Tare da kara wayar da kan jama'a game da kare muhalli, haɓakawa da bayar da shawarwarin sabbin makamashi a duniya ya sanya haɓakawa da aikace-aikacen motocin makamashin nan gaba. A lokaci guda kuma, abubuwan da ake buƙata don haɓakar kayan haɓakar ƙananan nauyi, amintaccen aikace-aikacen allo na aluminum, da ingancin saman su, girman su da kaddarorin injin suna ƙara girma da girma. Ɗaukar EV tare da nauyin abin hawa na 1.6t a matsayin misali, kayan haɗin aluminum yana da kusan 450kg, yana lissafin kimanin 30%. Lalacewar da ke bayyana a cikin tsarin samar da extrusion, musamman ma matsalar ƙwayar hatsi a kan ciki da waje, yana da matukar tasiri ga samar da bayanan martaba na aluminum kuma ya zama ƙwanƙwasa na ci gaban aikace-aikacen su.

Don bayanan bayanan da aka fitar, ƙira da ƙira na mutuwar extrusion suna da matuƙar mahimmanci, don haka bincike da haɓaka mutuwa don bayanan martabar aluminum na EV yana da mahimmanci. Bayar da hanyoyin magance kimiya da ma'ana mai ma'ana na iya ƙara haɓaka ƙwararrun ƙima da haɓaka haɓakar bayanan martaba na EV aluminum don biyan buƙatun kasuwa.

1 Matsayin Samfura

(1) Abubuwan da ake amfani da su, jiyya na ƙasa da kuma lalata sassan sassa da sassan za su bi ka'idodin da suka dace na ETS-01-007 "Bukatun Fasaha don Sassan Bayanan Bayanan Aluminum" da ETS-01-006 "Bukatun Fasaha don Jiyya na Anodic Oxidation Surface Jiyya".

(2) Jiyya na saman: Anodic hadawan abu da iskar shaka, farfajiyar dole ne ba ta da ƙananan hatsi.

(3) Ba a yarda saman sassan ya kasance da lahani kamar tsagewa da lanƙwasa. Ba a yarda sassan su gurɓata bayan oxidation.

(4) Abubuwan da aka haramta na samfurin sun dace da bukatun Q/JL J160001-2017 "Bukatun don Abubuwan da aka Haramta da Ƙuntatawa a cikin Abubuwan Mota da Kayan Aiki".

(5) Bukatun aikin injiniya: ƙarfin ƙarfi ≥ 210 MPa, ƙarfin yawan amfanin ƙasa ≥ 180 MPa, elongation bayan karaya A50 ≥ 8%.

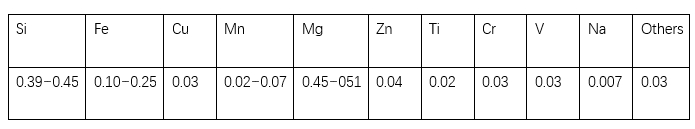

(6) Abubuwan buƙatun don abun da ke ciki na aluminium don sabbin motocin makamashi an nuna su a cikin Tebur 1.

2 Ingantawa da kwatankwacin nazari na tsarin mutuwar extrusion manyan yanke wuta yana faruwa

(1) Magani na al'ada 1: wato, don inganta ƙirar gaban extrusion mutu, kamar yadda aka nuna a cikin Hoto 2. Dangane da ra'ayin zane na al'ada, kamar yadda aka nuna ta kibiya a cikin adadi, ana sarrafa matsayi na haƙarƙari na tsakiya da matsayi na sublingual magudanar ruwa, babba da ƙananan magudanar ruwa suna 20 ° a gefe ɗaya, kuma ana amfani da magudanar ruwa H15 mm don samar da molten aluminum. An canja wuka mara komai a cikin sublingual a kusurwar dama, kuma narkar da aluminum ya kasance a kusurwa, wanda yake da sauƙi don samar da matattun yankuna tare da aluminum slag. Bayan samarwa, an tabbatar da iskar oxygen cewa saman yana da saurin kamuwa da matsalolin hatsi.

An yi abubuwan ingantawa na farko zuwa tsarin masana'anta na gargajiya:

a. Dangane da wannan nau'in, mun yi ƙoƙarin ƙara yawan samar da aluminum zuwa haƙarƙari ta hanyar ciyarwa.

b. Dangane da zurfin asali, zurfin wuka mara kyau na sublingual yana zurfafa, wato, an ƙara 5mm zuwa ainihin 15mm;

c. An faɗaɗa nisa na ruwan komai na sublingual da 2mm dangane da ainihin 14mm. Ana nuna ainihin hoton bayan ingantawa a hoto na 3.

Sakamakon tabbatarwa ya nuna cewa bayan abubuwan ingantawa na farko guda uku na sama, har yanzu akwai lahani na hatsi a cikin bayanan martaba bayan jiyya na iskar shaka kuma ba a warware su da kyau ba. Wannan yana nuna cewa shirin haɓakawa na farko har yanzu ba zai iya biyan buƙatun samar da kayan gami na aluminum don EVs ba.

(2) An gabatar da sabon tsari na 2 dangane da ingantawa na farko. An nuna ƙirar ƙira na Sabon Tsarin 2 a cikin Hoto 4. Bisa ga "ƙa'idar ruwa ta ƙarfe" da "dokar mafi ƙarancin juriya", ingantattun sassa na kera motoci suna ɗaukar tsarin ƙira na "bude baya rami". Matsayin haƙarƙari yana taka rawa a cikin tasirin kai tsaye kuma yana rage juriya; an tsara filin ciyarwa don zama "siffar murfin tukunya" kuma ana sarrafa matsayi na gada a cikin nau'in amplitude, manufar ita ce rage juriya na juriya, inganta haɓaka, da rage matsa lamba; gadar tana nutsewa gwargwadon yadda zai yiwu don hana matsalar ƙwayar hatsi a kasan gadar, kuma nisa na wuka mara kyau a ƙarƙashin harshen gadar ƙasa shine ≤3mm; Bambancin mataki tsakanin bel ɗin aiki da ƙananan bel ɗin aiki na mutuwa shine ≤1.0mm; wuka mara komai a ƙarƙashin harshen mutuƙar babba yana da santsi kuma a ko'ina yana canzawa, ba tare da barin shinge mai gudana ba, kuma an buga rami mai kafa kai tsaye kamar yadda zai yiwu; bel ɗin aiki tsakanin shugabannin biyu a tsakiyar haƙarƙari na ciki yana da ɗan gajeren lokaci kamar yadda zai yiwu, gabaɗaya yana ɗaukar ƙimar 1.5 zuwa sau 2 kauri na bango; magudanar magudanar ruwa yana da sauƙi mai sauƙi don saduwa da buƙatun isassun ruwa na aluminum na ƙarfe wanda ke gudana a cikin rami, yana ba da cikakkiyar yanayin da aka haɗa, kuma ba tare da barin wani yanki da ya mutu ba a kowane wuri (wukar da ba ta da komai a bayan babban mutuwa ba ta wuce 2 zuwa 2.5mm ba). Ana nuna kwatancen tsarin mutuwar extrusion kafin da bayan haɓakawa a cikin hoto na 5.

(3) Kula da haɓaka bayanan sarrafawa. Matsayin gada yana gogewa kuma an haɗa shi da kyau, bel ɗin aiki na sama da na ƙasa suna lebur, ƙarancin juriya yana raguwa, kuma ana haɓaka kwararar ƙarfe don rage nakasar da ba ta dace ba. Yana iya yadda ya kamata murkushe matsaloli kamar m hatsi da waldi, game da shi tabbatar da cewa haƙarƙari fitarwa matsayi da kuma gudun na gada tushen suna aiki tare da sauran sassa, da kuma m da kuma a kimiyyance danne surface matsaloli kamar m hatsi waldi a saman aluminum profile . Ana nuna kwatancen gabanin da bayan ingantaccen magudanar ruwa a cikin hoto na 6.

3 Tsarin extrusion

Don 6063-T6 aluminum gami don EVs, an ƙididdige ƙimar extrusion na tsagawar mutun don zama 20-80, kuma ƙimar extrusion na wannan kayan aluminium a cikin injin 1800t shine 23, wanda ya dace da bukatun aikin injin. Ana nuna tsarin extrusion a cikin Table 2.

Table 2 Extrusion tsarin samar da bayanan martaba na aluminum don hawan katako na sabbin fakitin baturi na EV

Kula da abubuwa masu zuwa lokacin extruding:

(1) An haramta zafi da molds a cikin wannan tanderun, in ba haka ba da mold zafin jiki zai zama m kuma crystallization zai faru da sauƙi.

(2) Idan wani mummunan rufewa ya faru a lokacin aikin extrusion, lokacin rufewa bazai wuce minti 3 ba, in ba haka ba dole ne a cire samfurin.

(3) An haramta komawa cikin tanderun don dumama sa'an nan kuma fitar da kai tsaye bayan rushewa.

4. Matakan gyaran gyare-gyare da tasirin su

Bayan ɗimbin gyare-gyaren gyare-gyare da gyare-gyare na gwaji, ana gabatar da shirin gyaran gyare-gyare mai dacewa.

(1) Yi gyare-gyare na farko da daidaitawa zuwa ainihin ƙirar:

① Yi ƙoƙarin nutse gada kamar yadda zai yiwu, kuma nisa na gada ya kamata ya zama ≤3mm;

② Bambancin mataki tsakanin bel ɗin aiki na kai da bel ɗin aiki na ƙananan ƙirar ya kamata ya zama ≤1.0mm;

③ Kada ku bar shingen kwarara;

④ Belin aiki a tsakanin shugabannin maza biyu a cikin haƙarƙari na ciki ya kamata ya zama takaice kamar yadda zai yiwu, kuma sauye-sauye na magudanar ruwa ya kamata ya zama santsi, babba da santsi kamar yadda zai yiwu;

⑤ Aiki bel na ƙananan mold ya kamata ya zama takaice kamar yadda zai yiwu;

⑥ Kada a bar yankin da ya mutu a kowane wuri (wuka mara komai bai kamata ya wuce 2mm ba);

⑦ Gyara gyare-gyare na sama tare da ƙananan hatsi a cikin rami na ciki, rage bel ɗin aiki na ƙananan ƙira da ƙaddamar da toshe kwarara , ko ba shi da shinge mai gudana kuma ya rage bel ɗin aiki na ƙananan mold.

(2) Dangane da ƙarin gyare-gyaren gyare-gyare da haɓakawa na samfurin da ke sama, ana yin gyare-gyaren gyare-gyare masu zuwa:

① Kawar da matattun yankuna na shugabannin maza biyu;

② Cire shingen kwarara;

③ Rage tsayin daka tsakanin kai da yanki mai aiki na ƙasa;

④ Rage ƙananan yankin aiki na mutu.

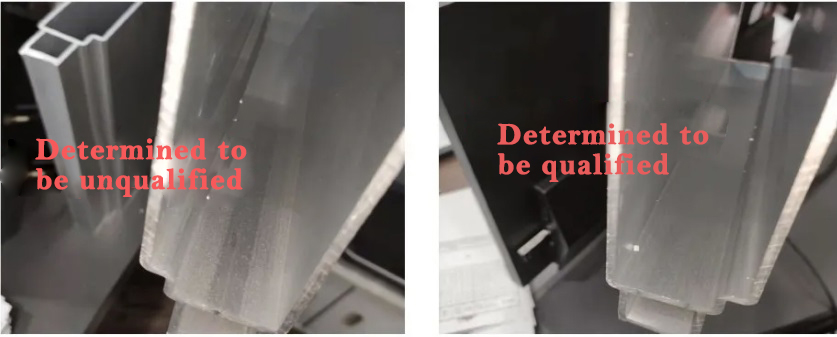

(3) Bayan gyaran gyare-gyare da ingantawa, ingancin samfurin da aka gama ya kai matsayi mai kyau, tare da haske mai haske kuma babu hatsi mai laushi, wanda zai magance matsalolin ƙwayar hatsi, walda da sauran lahani da ke wanzu a saman bayanan martaba na aluminum don EVs.

(4) Ƙarfin extrusion ya karu daga asali na 5 t / d zuwa 15 t / d, yana inganta ingantaccen samarwa.

5 Kammalawa

Ta hanyar haɓakawa da haɓaka ƙirar asali akai-akai, an warware babbar matsalar da ke da alaƙa da ƙaƙƙarfan hatsi a saman da walda bayanan bayanan aluminum don EVs gaba ɗaya.

(1) Raunan hanyar haɗin asali na asali, layin matsayi na haƙarƙari, an inganta shi da hankali. By kawar da matattu zones na biyu shugabannin, flattening da kwarara block , rage tsawo bambanci tsakanin kai da ƙananan mutu aiki zone , da kuma rage ƙananan mutu aiki yankin, da surface lahani na 6063 aluminum gami amfani a cikin irin wannan mota, kamar m hatsi da waldi, an samu nasarar shawo kan.

(2) Ƙarfin extrusion ya karu daga 5 t / d zuwa 15 t / d, yana inganta ingantaccen samarwa.

(3) Wannan nasara mai nasara na extrusion mutu zane da masana'antu shine wakilci kuma ana iya magana a cikin samar da bayanan martaba iri ɗaya kuma ya cancanci gabatarwa.

Lokacin aikawa: Nuwamba-16-2024