1 Bayani

Tsarin samarwa na bayanin martabar rufin thermal yana da ɗan rikitarwa, kuma tsarin zaren da laminating ya ɗan yi latti. Abubuwan da aka gama kammalawa waɗanda ke gudana cikin wannan tsari ana kammala su ta hanyar aiki tuƙuru na ma'aikatan gaba-gaba da yawa. Da zarar kayan sharar sun bayyana a cikin tsarin tsiro, za su Idan ya haifar da asara mai tsanani na tattalin arziki, zai haifar da asarar yawancin sakamakon aikin da ya gabata, wanda zai haifar da sharar gida mai yawa.

A lokacin samar da thermal insulation zaren bayanan martaba, bayanan martaba galibi ana goge su saboda dalilai daban-daban. Babban abin da ke haifar da tarkace a cikin wannan tsari shine tsagewar ƙwanƙolin tsiri mai hana zafi. Akwai dalilai da yawa da ke haifar da tsagewar tsiri mai hana zafi, a nan mun fi mayar da hankali ne kan tsarin gano dalilan da ke haifar da lahani kamar wutsiya mai ruɗi da rarrabuwar kawuna da tsarin extrusion ke haifar da shi, wanda ke haifar da tsattsage bayanan martaba na allo na aluminum gami da bayanan kula da yanayin zafi a lokacin zaren da laminating, da magance wannan matsala ta hanyar inganta mold da sauran hanyoyin.

2 Matsaloli masu tasowa

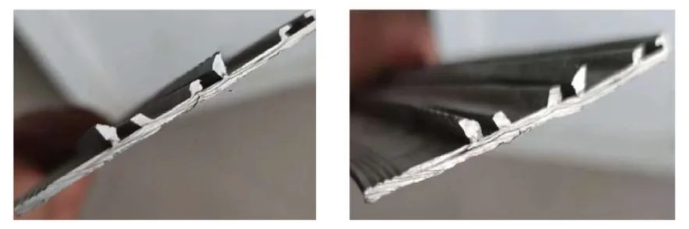

A lokacin aikin samar da kayan aikin da aka haɗa na bayanan zaren zaren zafi, kwatsam ya bayyana fashe-fashe na ƙima mai hana zafi. Bayan dubawa, abin fashewa yana da wani tsari. Duk ya fashe a ƙarshen wani samfurin, kuma tsayin tsaga duk iri ɗaya ne. Yana cikin wani kewayon (20-40cm daga ƙarshe), kuma zai dawo al'ada bayan ɗan lokaci na fashe. Hotunan bayan tsaga ana nuna su a Hoto na 1 da Hoto na 2.

3 Nemo matsala

1) Da farko, a rarraba bayanan da ke da matsala kuma a adana su tare, bincika abin da ya faru daya bayan daya, kuma gano abubuwan gama gari da bambance-bambance a cikin tsagewa. Bayan bin diddigin maimaitawa, lamarin fashewa yana da takamaiman tsari. Duk ya fashe a ƙarshen samfurin guda ɗaya. Siffar ƙirar ƙira wani abu ne na kowa ba tare da rami ba, kuma tsayin daka yana cikin wani yanki. A cikin (20-40cm daga ƙarshe), zai dawo al'ada bayan fashe na ɗan lokaci.

2) Daga katin sa ido na samfurin wannan tsari na bayanan martaba, zamu iya gano lambar ƙira da aka yi amfani da ita wajen samar da wannan nau'in, yayin samarwa, ana gwada girman girman girman wannan ƙirar, kuma girman geometric na tsiri mai rufin zafi, kayan injin bayanan martaba da taurin saman duk suna cikin kewayon da ya dace.

3) A lokacin tsarin samar da kayan aiki, an bi diddigin sigogin tsari da ayyukan samarwa. Babu rashin daidaituwa, amma har yanzu akwai fashe lokacin da aka samar da rukunin bayanan martaba.

4) Bayan duba karaya a tsagewar, an sami wasu tsarukan da aka dakatar. Ganin cewa dalilin wannan al'amari ya kamata ya faru ne ta hanyar lahani na extrusion wanda tsarin extrusion ya haifar.

5) Daga abin da ya faru a sama, za a iya ganin cewa dalilin tsagewar ba shine taurin bayanin martaba da tsarin tsari ba, amma an ƙaddara shi da farko ta hanyar lahani na extrusion. Domin a kara tabbatar da musabbabin matsalar, an yi gwaje-gwaje kamar haka.

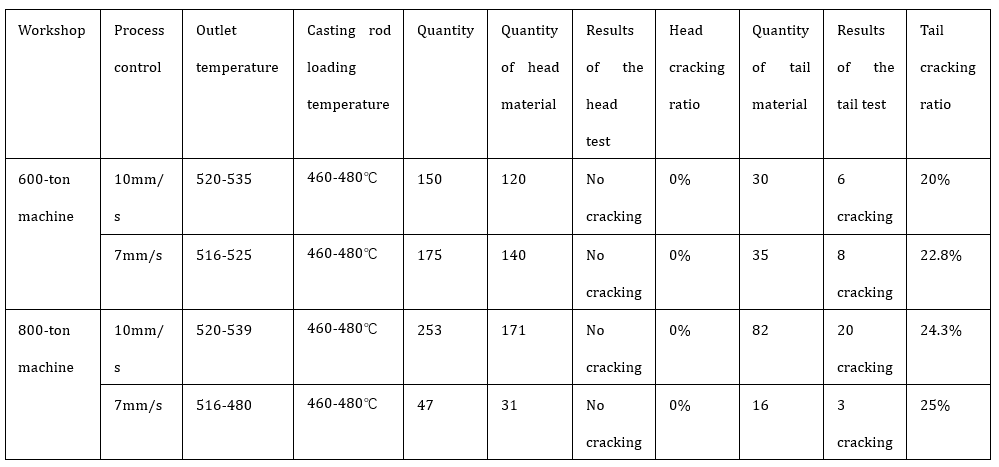

6) Yi amfani da tsari iri ɗaya don gudanar da gwaje-gwaje akan injunan ton daban-daban tare da saurin extrusion daban-daban. Yi amfani da injin tan 600 da injin tan 800 don gudanar da gwajin bi da bi. Alama kan abu da wutsiya dabam dabam kuma shirya su cikin kwanduna. Taurin bayan tsufa a 10-12HW. An yi amfani da hanyar lalata ruwa na alkaline don gwada bayanin martaba a kai da wutsiya na kayan. An gano cewa wutsiya na abu yana da raguwar wutsiya da abubuwan ban mamaki. An gano dalilin tsagewar da wutsiya mai rugujewa da ƙullawa. Hotunan bayan etching alkali an nuna su a cikin hotuna na 2 da 3. An gudanar da gwaje-gwaje masu yawa akan wannan rukunin bayanan don duba abin da ya faru. Ana nuna bayanan gwajin a Table 1.

Hoto na 2 da 3

7) Daga bayanan da ke cikin teburin da ke sama, ana iya ganin cewa babu wani fashewa a kan kayan, kuma yawan raguwa a wutsiya na kayan shine mafi girma. Dalilin tsagewar ba shi da alaƙa da girman injin da saurin injin ɗin. Matsakaicin raguwa na kayan wutsiya shine mafi girma, wanda ke da alaƙa kai tsaye da tsayin sawing na kayan wutsiya. Bayan an jiƙa ɓangaren tsagewa a cikin ruwan alkaline kuma an gwada shi, wutsiya mai ruɗi da ƙwanƙwasa zai bayyana. Da zarar an yanke wutsiya mai raguwa da sassan sassa, ba za a sami fashewa ba.

4 Hanyoyin magance matsalolin da matakan rigakafi

1) Don rage ƙwanƙwasa ƙirƙira da wannan dalili ke haifarwa, haɓaka yawan amfanin ƙasa, da rage sharar gida, ana ɗaukar matakan sarrafawa masu zuwa. Wannan bayani ya dace da wasu samfurori masu kama da wannan samfurin inda extrusion mutu ya mutu. Ƙunƙarar wutsiya da abubuwan ban mamaki da aka samar a lokacin samar da extrusion za su haifar da matsalolin inganci kamar fashewar ƙarshen ƙima yayin haɗuwa.

2) Lokacin karɓar mold, tsananin sarrafa girman daraja; yi amfani da yanki ɗaya na abu guda ɗaya don yin gyare-gyare na haɗin gwiwa, ƙara ɗakunan waldawa biyu zuwa ƙirar, ko buɗe ƙirar tsaga na ƙarya don rage ingancin tasirin wutsiya da ƙima akan samfurin da aka gama.

3) A lokacin samar da extrusion, saman sandar aluminum dole ne ya kasance mai tsabta kuma ba tare da ƙura, mai da sauran gurɓata ba. Tsarin extrusion ya kamata ya ɗauki yanayin extrusion a hankali a hankali. Wannan na iya rage saurin fitarwa a ƙarshen extrusion kuma ya rage raguwar wutsiya da ƙima.

4) Low zafin jiki da kuma high gudun extrusion ana amfani a lokacin extrusion samar, da kuma yawan zafin jiki na aluminum sanda a kan inji ana sarrafa tsakanin 460-480 ℃. The mold zafin jiki ne sarrafawa a 470 ℃ ± 10 ℃, da extrusion ganga zafin jiki ne sarrafawa a game da 420 ℃, da extrusion kanti zafin jiki ne sarrafawa tsakanin 490-525 ℃. Bayan extrusion, ana kunna fan don sanyaya. Ya kamata a ƙara tsawon ragowar da fiye da 5mm fiye da yadda aka saba.

5) Lokacin samar da irin wannan bayanin martaba, yana da kyau a yi amfani da na'ura mafi girma don ƙara ƙarfin extrusion, inganta matakin haɗin ƙarfe, da tabbatar da yawan kayan.

6) A lokacin samar da extrusion, dole ne a shirya guga ruwa na alkali a gaba. Mai aiki zai ga wutsiya na kayan don duba tsawon wutsiya mai rugujewa da daidaitawa. Baƙaƙen ratsi a saman alkali-etched suna nuna cewa raguwar wutsiya da ƙima sun faru. Bayan ci gaba da sawing, Har sai ɓangaren giciye yana da haske kuma ba shi da ratsan baki, duba sandunan aluminum 3-5 don ganin tsawon ya canza bayan wutsiya da raguwa. Don kauce wa raguwar wutsiya da ɓacin rai daga kawowa ga samfuran bayanan martaba, an ƙara 20cm bisa ga mafi tsayi, ƙayyade tsayin tsayin wutsiya na ƙirar ƙira, cire ɓangaren matsala kuma fara sawa cikin samfurin da aka gama. A lokacin aiki, kai da wutsiya na kayan za a iya yin tagulla da sassaƙa sassa, amma ba dole ba ne a kawo lahani ga samfurin bayanin martaba. Ana kulawa da dubawa ta hanyar duba ingancin injin. Idan tsayin wutsiya mai raguwa da rarrabuwa ya shafi yawan amfanin ƙasa, cire mold ɗin a cikin lokaci kuma a datse ƙirar har sai ya zama al'ada kafin a fara samar da al'ada.

5 Takaitawa

1) An gwada batches da yawa na bayanan bangon da ke hana zafi da aka samar ta amfani da hanyoyin da ke sama kuma ba a sami fashewa mai kama da haka ba. Ƙididdiga masu ƙima na bayanan martaba duk sun kai daidaitattun GB / T5237.6-2017 bukatun "Aluminum Alloy Building Profiles No. 6 Part: for Insulating Profiles".

2) Don hana faruwar wannan matsala, an samar da tsarin dubawa na yau da kullun don magance matsalar cikin lokaci tare da yin gyare-gyare don hana bayanan martaba masu haɗari daga shiga cikin tsari mai haɗaka da rage ɓarna a cikin aikin samarwa.

3) Bugu da kari ga guje wa fatattaka lalacewa ta hanyar extrusion lahani, shrink wutsiya da stratification, ya kamata mu ko da yaushe kula da fatattaka sabon abu lalacewa ta hanyar dalilai kamar lissafi na daraja, da surface taurin da inji Properties na abu da tsari sigogi na hadawa tsari.

May Jiang ta gyara daga MAT Aluminum

Lokacin aikawa: Juni-22-2024