Aluminum simintin gyare-gyare hanya ce don samar da babban juriya da sassa masu inganci ta hanyar zuba narkakkar aluminum a cikin ingantaccen ƙira da ƙima mai ƙima, ƙira, ko tsari. Yana da ingantaccen tsari don samar da hadaddun, sassauƙa, cikakkun bayanai waɗanda suka dace daidai da ƙayyadaddun ƙirar asali.

Tsarin Simintin Aluminum

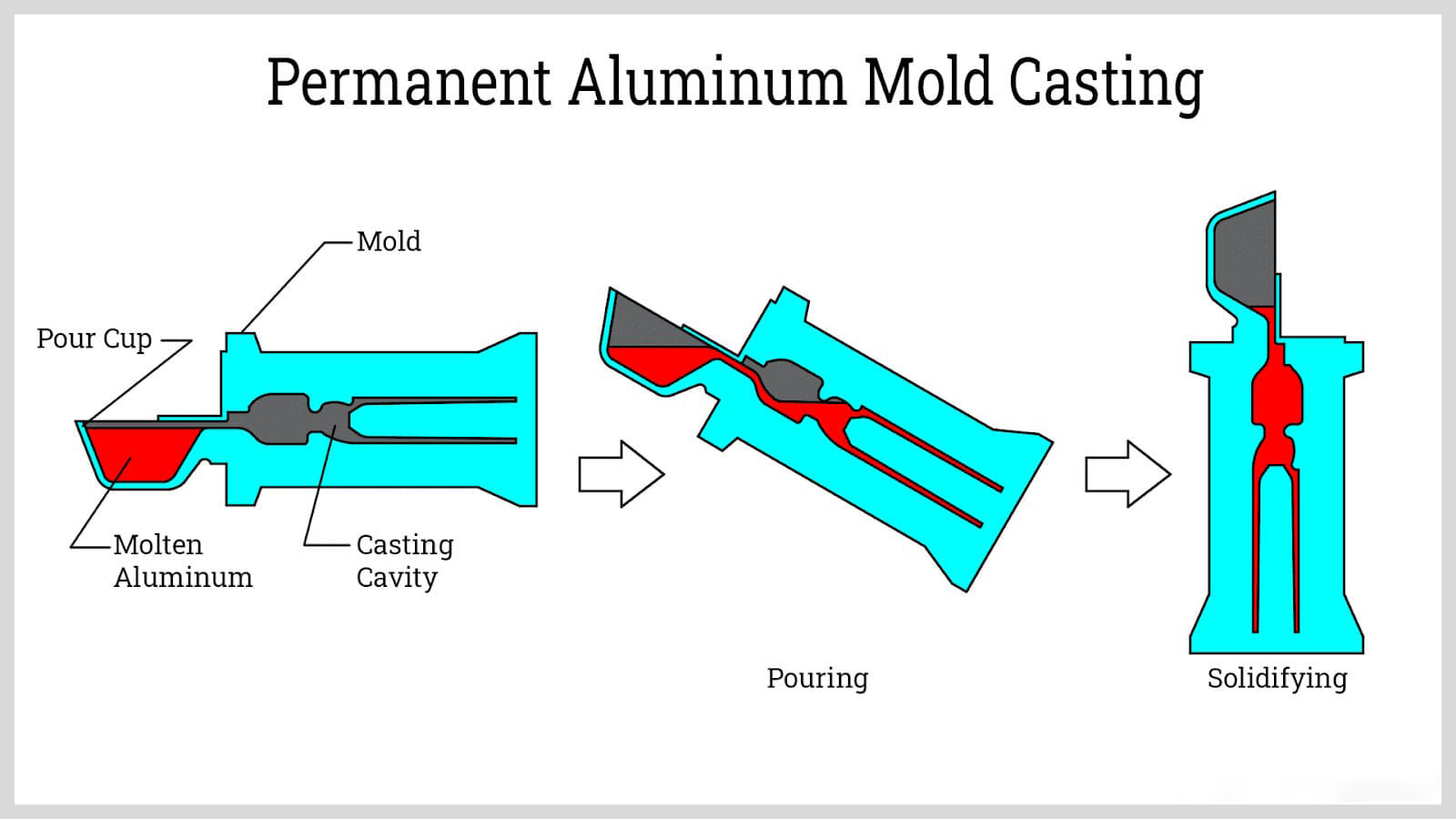

1. Dindindin Simintin gyare-gyare

Yawancin kuɗin da ake kashewa na simintin gyare-gyaren aluminum na dindindin shine gyare-gyare da gyare-gyare na ƙirar, wanda yawanci ana yin shi daga ƙarfe mai launin toka ko karfe. An tsara nau'in nau'in nau'in nau'i na geometric na ɓangaren da aka tsara tare da ƙayyadaddun bayanai da siffar ɓangaren zuwa kashi biyu. A cikin aikin allurar, ana rufe rabin ƙullun ta yadda babu iska ko gurɓataccen abu. Ana ɗora ƙuran kafin a zubar da narkakkar aluminum, wanda za'a iya ɗora, zuba, ko allura.

A ƙarshen tsari, ana ba da izini don yin sanyi don ƙyale ɓangaren aluminum ya ƙarfafa. Da zarar an sanyaya, an cire ɓangaren da sauri daga ƙirar don hana samuwar lahani.

Komai yadda tsarin zai iya zama mai sauƙi, hanya ce ta kimiyya da fasaha don samar da sassa masu girma.

2.Yashi Casting

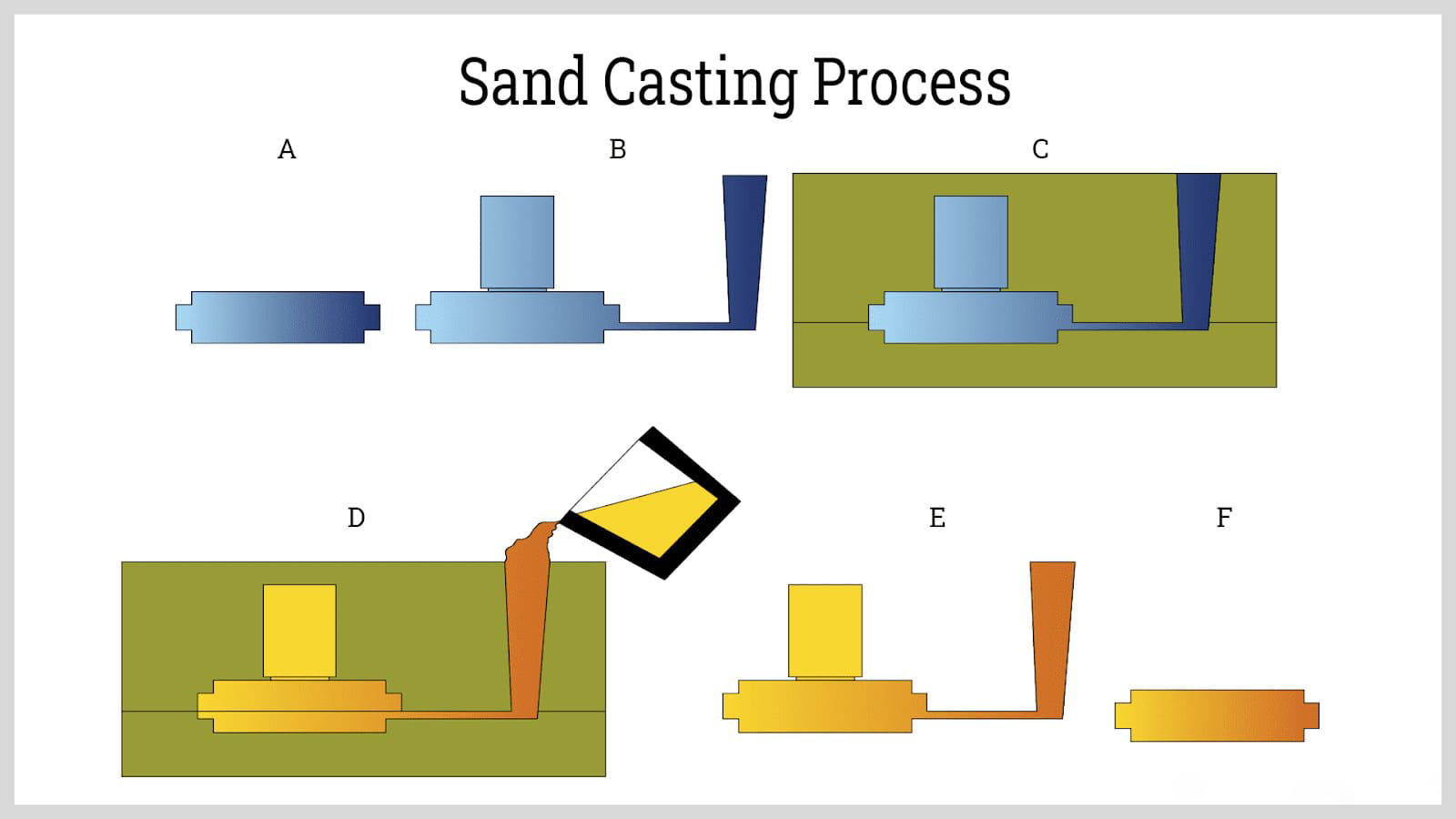

Tsarin simintin yashi ya ƙunshi tattara yashi a kusa da tsarin sake amfani da shi wanda ke da siffa, cikakkun bayanai, da daidaitawar samfurin ƙarshe. Haɗe a cikin ƙirar akwai masu tashi waɗanda ke ba da damar zub da narkakkar ƙarfe a cikin ƙirar kuma don aluminium mai zafi don ciyar da simintin gyare-gyare yayin ƙarfafawa don hana haɓakar porosity.

Ƙunshe a cikin ƙirar akwai sprue wanda ke ba da damar sanya narkakkar ƙarfe a cikin ƙirar. Girman ƙirar sun ɗan fi girma fiye da samfurin don lissafin raguwa yayin aikin sanyaya. Yashi yana da nauyi da ƙarfi don kula da siffar ƙirar kuma yana da juriya don yin hulɗa tare da narkakken ƙarfe.

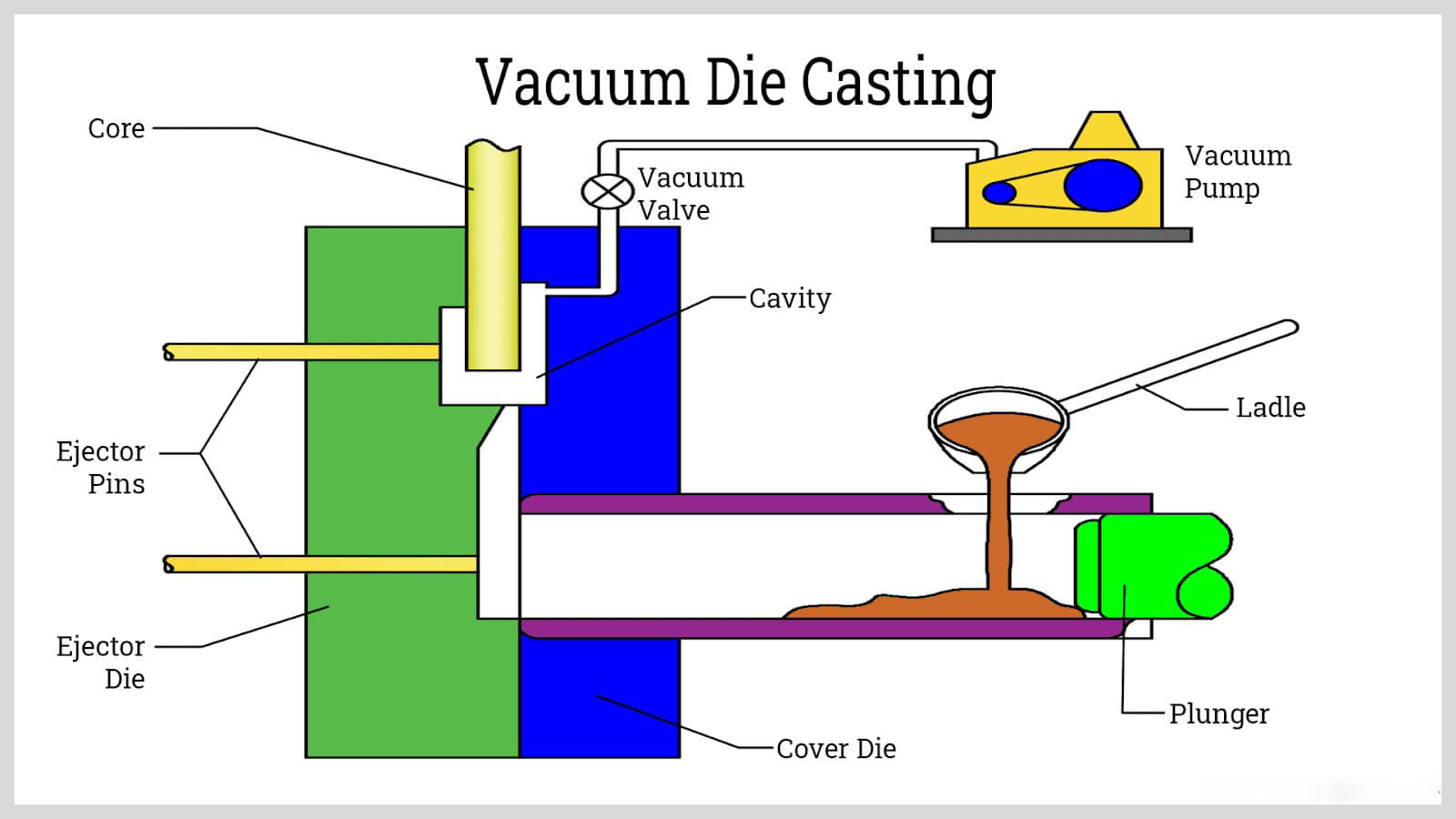

4.Vacuum Die Casting

4.Vacuum Die Casting Vacuum die simintin yana amfani da gidan kararrawa mara iska wanda ke da buɗaɗɗen buɗaɗɗen buɗaɗɗiya a ƙasa da mashigar injin a sama. Tsarin yana farawa ta hanyar nutsar da sprue a ƙasa da narkakken aluminum. An ƙirƙiri vacuum a cikin mai karɓa yana haifar da bambancin matsa lamba tsakanin rami mai mutu da narkakken aluminium a cikin crucible.

Bambancin matsin lamba yana haifar da narkakkar aluminum don gudana sama da sprue cikin rami mai mutu, inda narkakkar aluminum ta ƙarfafa. Ana cire mutuwa daga mai karɓa, buɗewa, kuma an fitar da sashin.

Sarrafa vacuum da bambancin matsa lamba tsakanin rami mai mutu da narkakken aluminium yana ba da damar sarrafa ƙimar cika da ake buƙata ta ƙirar ɓangaren da buƙatun gating. Sarrafa adadin cika yana haɓaka ikon tantance ingancin ɓangaren da aka gama.

Samun sprue da aka nutsar a ƙarƙashin saman narkakkar aluminum yana tabbatar da cewa narkar da aluminum zai zama mafi tsaftataccen gami da ba shi da oxides da ɗigo. Sassan suna da tsabta da sauti tare da ƙarancin kayan waje.

5.Cin Jari

Yin simintin saka hannun jari, wanda kuma aka sani da simintin kakin zuma da aka rasa, yana farawa da allura da kakin zuma a cikin mutu don ƙirƙirar ƙirar ƙãre samfurin. An haɗa sifofin da aka yi da kakin zuma zuwa sprue don samar da tsarin tsarin itace. Ana tsoma bishiyar a cikin slurry sau da yawa, wanda ke samar da harsashi mai ƙarfi na yumbu a kusa da siffar kakin zuma.

Da zarar yumbura ya saita kuma ya taurare, ana dumama shi a cikin autoclave don kammala ƙonawar dewax. Don cimma kyakkyawan zafin jiki na harsashi, an riga an riga an cika shi da narkakken aluminum, wanda aka zuba a cikin sprue kuma ya wuce ta jerin masu gudu da ƙofofi a cikin gyare-gyare. Lokacin da sassan suka taurare, yumbura yana ƙwanƙwasa yana barin sassan da aka haɗa itace da za a yanke daga itacen.

6.Rasa Kumfa

Bacewar tsarin simintin kumfa wani nau'in simintin saka hannun jari ne inda aka maye gurbin kakin zuma da kumfa polystyrene. Anyi gyare-gyaren ƙirar daga polystyrene a cikin taron tari kamar mai gudu da ɓangarorin saka hannun jari. Ana shigar da beads na polystyrene a cikin gyare-gyaren aluminum masu zafi a ƙananan matsa lamba tare da ƙara tururi don faɗaɗa polystyrene don cika ramukan.

Ana sanya tsarin a cikin busasshen yashi mai cike da ɗimbin jijjiga don kawar da ɓarna ko aljihunan iska. Yayin da aka zuba narkakken aluminum a cikin yashi, kumfa yana ƙonewa, kuma ana yin simintin.

Aikace-aikace gama gari Na Simintin Aluminum

Saboda kyawawan halayensa na zahiri da sinadarai, manyan masana'antu da yawa suna amfani da simintin aluminum. Anan akwai 'yan aikace-aikacen gama gari na kayan.

1. Masana'antar Likita

Masu kera sashin likitanci sun dogara da simintin gyare-gyaren aluminum don ƙarfinsu da nauyi a cikin yin gyaran fuska, tiren tiyata, da sauransu. Baya ga haka, tsarin ya dace da yin sarƙaƙƙiya da ingantattun siffofi waɗanda masana'antar ta shahara da su. Har ila yau, aluminum shine kayan da ya dace saboda juriya na lalata tun lokacin da yawancin kayan aikin likita suna haɗuwa da ruwan jiki.

2. Masana'antar kera motoci

Masu kera sassan mota sun dogara da simintin gyare-gyare na aluminum don kaddarorinsu masu nauyi ba tare da sun ƙunshi ƙarfi da dorewa ba. A sakamakon haka, ya inganta ingancin man fetur. Bugu da ƙari, yin sassa na mota tare da hadaddun sifofi tare da tsarin simintin aluminum yana da sauƙi. Simintin gyare-gyare na aluminum sun dace don yin sassa kamar birki da tuƙi.

3. Masana'antar Abinci

Aluminum Cast yana da amfani a cikin masana'antar dafa abinci saboda ƙarfinsa, juriyar lalata, nauyi mai nauyi, da kyakkyawan yanayin zafi. Baya ga haka, kayan sun dace da yin girki saboda kyakkyawan yanayin zafi, watau yana iya yin zafi da sanyi da sauri.

4. Masana'antar Jiragen Sama

Sassan Aluminum sun dace da masana'antar jirgin sama saboda nauyi da ƙarfi. Nauyinsa mai sauƙi yana ba da damar jirgin sama ya yi amfani da ƙarancin mai don ɗaukar nauyi.

Source:

https://www.iqsdirectory.com/articles/die-casting/aluminum-casting.html

https://waykenrm.com/blogs/cast-aluminum/#Common-Applications-of-Casting-Aluminum

May Jiang ta gyara daga MAT Aluminum

Lokacin aikawa: Yuli-26-2023