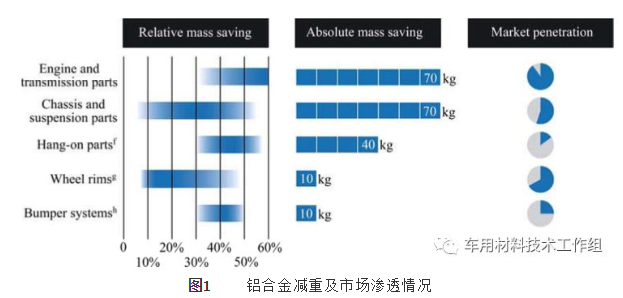

Masana'antar kera motoci ta Turai ta shahara saboda ci gaba da sabbin abubuwa. Tare da haɓaka manufofin ceton makamashi da manufofin rage fitar da iska, don rage yawan amfani da man fetur da iskar carbon dioxide, ingantattun abubuwan da aka tsara da ƙira na aluminum ana amfani da su sosai a cikin ƙirar mota. Bisa kididdigar da aka yi, a cikin shekaru goma da suka wuce, matsakaicin adadin aluminum da ake amfani da shi a cikin motocin fasinja ya ninka sau biyu, kuma an nuna nauyin rage nauyin aluminum a cikin hoto na 1 da ke ƙasa. Dangane da sabbin dabarun ƙira, wannan yanayin zai ci gaba a cikin ƴan shekaru masu zuwa.

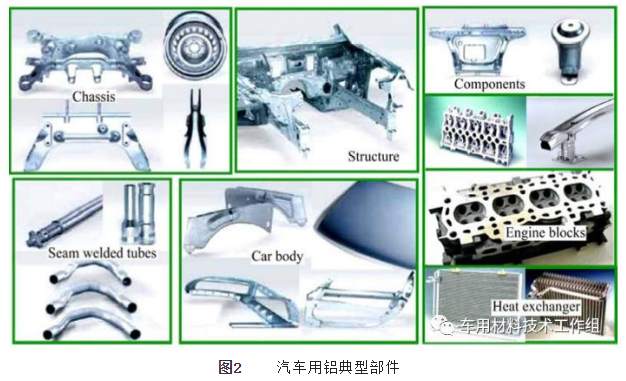

A cikin tsarin ci gaba mai sauƙi, kayan aikin aluminum suna fuskantar gasa mai tsanani tare da wasu sababbin kayan aiki, irin su ƙarfe mai ƙarfi, wanda har yanzu zai iya kula da karfi bayan zane-zane na bakin ciki. Bugu da ƙari, akwai magnesium, titanium, gilashi ko carbon fiber composite kayan, wanda na karshen wanda aka riga yadu amfani a cikin sararin samaniya. Yanzu an haɗa manufar ƙirar abubuwa da yawa a cikin ƙirar mota, kuma ana ƙoƙarin yin amfani da kayan da suka dace zuwa sassa masu dacewa. Kalubale mai mahimmanci shine matsalar haɗin gwiwa da jiyya na sama, kuma an samar da mafita daban-daban, irin su injin toshewa da kayan aikin jirgin ƙasa, ƙirar firam (Audi A2, A8, BMW Z8, Lotus Elise), tsarin farantin bakin ciki (Honda NSX, Jaguar, Rover), dakatarwa (DC-E class, Renault, Peugeot) da sauran abubuwan ƙirar tsarin. Hoto na 2 yana nuna sassan aluminum da ake amfani da su a cikin motoci.

Dabarun Zane na BIW

Jiki-in-fari shine mafi nauyi a cikin motar al'ada, yana lissafin kashi 25% zuwa 30% na nauyin abin hawa. Akwai zane-zane guda biyu a cikin tsarin jiki-in-fari.

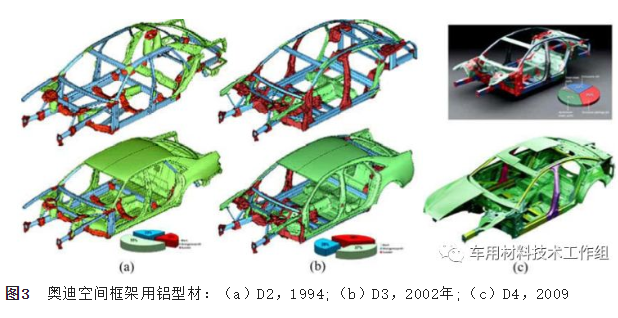

1"Profile space frame design" don ƙananan motoci masu girma da matsakaici: Audi A8 ne na hali misali, jiki a cikin farin nauyi 277 kg, kunshi 59 profiles (61 kg), 31 simintin (39 kg) da kuma 170 sheet karfe (177 kg). An haɗa su da riveting, MIG waldi, walƙiya Laser, sauran matasan walda, gluing, da dai sauransu.

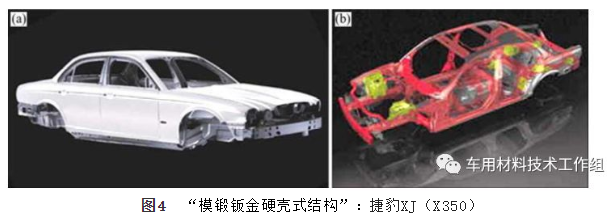

2. "Die-kirgire sheet karfe monocoque tsarin" for matsakaici zuwa manyan-iya aiki mota aikace-aikace: misali, Jaguar XJ (X350), 2002 model (kamar yadda aka nuna a Figure 4 kasa), 295 kg taro "stamped jiki monocoque tsarin" jiki-in-farar kunshi 22 profiles (21 kg), 15 simintin (15 kg) da 273 sheet karfe sassa (259 kg). Hanyoyin haɗin sun haɗa da haɗin gwiwa, riveting, da walda na MIG.

Aikace-aikacen Alloy na Aluminum akan Jiki

1. Shekaru taurare Al-Mg-Si gami

Siffofin 6000 sun ƙunshi magnesium da silicon kuma a halin yanzu ana amfani da su a cikin zanen jikin mota kamar A6016, A6111 da A6181A. A Turai, 1-1.2mm EN-6016 yana da kyakkyawan tsari da juriya na lalata kuma ana amfani dashi ko'ina.

2. Al-Mg-Mn alloy mara zafi magani

Saboda ƙayyadaddun ƙarfin ƙarfin sa, Al-Mg-Mn alloys suna nuna kyakkyawan tsari da ƙarfi mai ƙarfi, kuma ana amfani da su sosai a cikin zanen gado mai zafi da sanyi mai birgima da bututun hydroformed. Aikace-aikace a cikin chassis ko ƙafafun sun fi tasiri saboda yawan raguwar sassa masu motsi da ba a so su bugu da ƙari yana haɓaka jin daɗin tuƙi kuma yana rage matakan amo.

3. Aluminum profile

A cikin Turai, an gabatar da sabbin dabarun mota gabaɗaya bisa ƙirar bayanan martabar aluminium, alal misali, firam ɗin alloy na aluminium da hadaddun sassa. Babban yuwuwar su don ƙira masu rikitarwa da haɗin kai na aiki ya sa su fi dacewa don samar da jerin ƙididdiga masu inganci. Domin quenching ake bukata a lokacin extrusion, matsakaici ƙarfi 6000 da high ƙarfi 7000 shekaru hardenable gami ana amfani. Ana sarrafa tsari da ƙarfi na ƙarshe ta hanyar taurin shekaru ta dumama na gaba. Aluminum gami bayanan martaba ana amfani da su musamman a ƙirar firam, igiyoyin haɗari da sauran abubuwan haɗin gwiwa.

4. Fitar da aluminum

Simintin gyare-gyare sune mafi yawan abubuwan da ake amfani da su na aluminum a cikin motoci, kamar tubalan injin, kawunan silinda da abubuwan chassis na musamman. Hatta injunan dizal, waɗanda suka ƙaru sosai a kasuwanninsu a Turai, suna jujjuya zuwa simintin aluminum saboda karuwar buƙatun ƙarfi da dorewa. A lokaci guda kuma, ana amfani da simintin gyare-gyaren aluminium a cikin ƙirar firam, sassan shaft da sassa na tsari, da babban simintin gyare-gyare na sabon AlSiMgMn aluminum gami ya sami babban ƙarfi da ductility.

Aluminum kayan zaɓi ne don aikace-aikacen kera da yawa kamar chassis, jiki da yawancin abubuwan tsarin saboda ƙarancin ƙarancinsa, kyakkyawan tsari da kyakkyawan juriya na lalata. Aluminum da aka yi amfani da shi a cikin ƙirar tsarin jiki na iya cimma aƙalla raguwar nauyi 30% a ƙarƙashin jigo na biyan buƙatun aiki. Hakanan, ana iya amfani da allunan aluminium zuwa yawancin sassan murfin na yanzu. A wasu lokuta tare da babban ƙarfin buƙatun, 7000 jerin gami na iya har yanzu kula da fa'idodin inganci. Sabili da haka, don aikace-aikacen girma mai girma, mafitacin rage girman allo na aluminum shine mafi kyawun hanyar tattalin arziki.

May Jiang ta gyara daga MAT Aluminum

Lokacin aikawa: Dec-08-2023