Anodizing wani tsari ne da ake amfani da shi don ƙirƙirar fim ɗin aluminum oxide a saman saman aluminum ko aluminum gami kayayyakin. Ya haɗa da sanya samfurin aluminum ko aluminum a matsayin anode a cikin maganin lantarki da kuma amfani da wutar lantarki don samar da fim din aluminum oxide. Anodizing yana inganta juriya na lalata, juriya, da kayan ado na bayanan martaba na aluminum. Yayin aiwatar da anodizing na bayanan martaba na aluminum, fasalulluka na lahani da yawa na iya faruwa. Bari mu fara fahimtar abubuwan da ke haifar da lahani. Lalacewar kayan abu, gurɓataccen wanka, hazo na alloy matakai na biyu, ko tasirin galvanic na iya haifar da lahani. An bayyana su kamar haka:

1.Acid ko alkali etching

Kafin anodizing, aluminium abu na iya zama gurɓata ta acid ko alkaline ruwaye, ko kuma a shafa da acid ko alkaline tururi, haifar da gida fili aibobi a saman. Idan lalata ta yi tsanani, manyan wuraren rami na iya haifarwa. Yana da wahala a iya tantancewa da tsiraicin ko lalatawar acid ko alkali ne ke haifar da shi, amma ana iya bambanta shi cikin sauƙi ta hanyar lura da sashin da ya lalace a ƙarƙashin na'urar hangen nesa. Idan kasan ramin zagaye ne kuma ba tare da lalata intergranular ba, yana haifar da etching alkali. Idan kasan ba daidai ba ne kuma yana tare da lalatawar intergranular, tare da ramuka masu zurfi, ana haifar da etching acid. Rashin ajiya da kulawa da kyau a cikin masana'anta kuma na iya haifar da irin wannan lalata. Turin Acid daga sinadarai masu gogewa ko wasu tururin acidic, da kuma masu rage ƙorafin chlorinated, sune tushen fitar da acid. Etching na alkali na yau da kullun yana faruwa ta hanyar watsawa da zubar da turmi, toka siminti, da ruwan wanke alkaline. Da zarar an gano dalilin, ƙarfafa gudanar da ayyuka daban-daban a cikin masana'anta na iya magance matsalar.

2.Atmospheric lalata

Bayanan martaba na aluminum da aka fallasa ga iska mai ɗanɗano na iya haɓaka farar tabo, waɗanda galibi suna daidaitawa tare da layin mold. Lalacewar yanayi gabaɗaya baya da ƙarfi kamar acid ko alkali etching kuma ana iya cire ta ta hanyoyin inji ko wanke alkaline. Lalacewar yanayi galibi ba ta zama wuri ba kuma tana faruwa akan wasu filaye, kamar ƙananan wuraren zafin jiki inda tururin ruwa ke takurawa cikin sauƙi ko saman saman sama. Lokacin da lalata yanayi ya fi tsanani, ɓangaren giciye na wuraren rami yana bayyana kamar namomin kaza. A wannan yanayin, wankewar alkaline ba zai iya kawar da wuraren ramuka ba kuma yana iya kara girman su. Idan an ƙaddara lalatawar yanayi, yakamata a bincika yanayin ajiya a masana'anta. Kada a adana kayan aluminium a wuraren da ke da ƙananan yanayin zafi don hana tururin ruwa. Wurin ajiya ya kamata ya bushe, kuma zafin jiki ya kamata ya zama iri ɗaya kamar yadda zai yiwu.

3. Lalacewar takarda (tabobin ruwa)

Lokacin da aka sanya takarda ko kwali tsakanin kayan aluminium ko amfani da shi don marufi, yana hana abrasion. Duk da haka, idan takardar ta zama datti, ɓarna suna bayyana a saman aluminum. Lokacin da aka yi amfani da kwali, layukan lalata na yau da kullun suna bayyana a wuraren hulɗa da katako. Ko da yake a wasu lokuta ana iya ganin lahani kai tsaye akan saman aluminum, galibi ana bayyana su bayan wankewar alkaline da anodizing. Waɗannan tabo gaba ɗaya suna da zurfi kuma suna da wahala a cire su ta hanyar inji ko wanke alkaline. Rushewar takarda ( allo) yana haifar da ions acid, galibi SO42- da Cl-, waɗanda ke cikin takarda. Sabili da haka, yin amfani da takarda (kwandali) ba tare da chlorides da sulfates ba da kuma guje wa shiga cikin ruwa sune hanyoyi masu tasiri don hana takarda (kwal) lalata.

4.Cleaning ruwa lalata (kuma aka sani da snowflake lalata)

Bayan wankin alkaline, gogewar sinadarai, ko tsinken acid sulfuric, idan ruwan kurkurewar ya ƙunshi najasa, zai iya haifar da tabo mai siffar tauraro ko kyalli a saman. Zurfin lalata ba shi da zurfi. Irin wannan lalata yana faruwa a lokacin da ruwan tsaftacewa ya gurɓata sosai ko kuma lokacin da yawan zubar da ruwa ya yi ƙasa. Ya yi kama da lu'ulu'u masu siffar dusar ƙanƙara a cikin bayyanar, don haka sunan "lalata dusar ƙanƙara." Dalilin shine amsawa tsakanin ƙazantattun zinc a cikin aluminum da SO42- da Cl- a cikin ruwan tsaftacewa. Idan rufin tanki ba shi da kyau, tasirin galvanic zai iya tsananta wannan lahani. A cewar majiyoyin waje, lokacin da abun ciki na Zn a cikin aluminum alloy ya fi 0.015%, Cl- a cikin ruwa mai tsabta ya fi 15 ppm, irin wannan lalata zai iya faruwa. Yin amfani da acid nitric don pickling ko ƙara 0.1% HNO3 zuwa ruwan tsaftacewa zai iya kawar da shi.

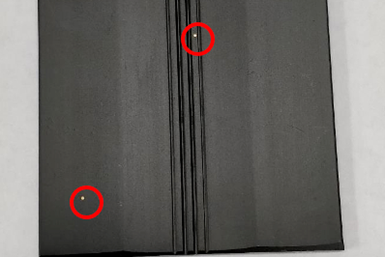

5.Cloride lalata

Kasancewar ƙaramin adadin chloride a cikin sulfuric acid anodizing bath shima zai iya haifar da lalata. Siffar bayyanar ita ce ramuka mai siffar tauraro mai zurfi mai zurfi, wanda ya fi mayar da hankali a gefuna da sasanninta na workpiece ko a wasu wurare tare da mafi girma na yanzu. Wuraren rami ba su da fim ɗin anodized, kuma kauri na fim ɗin a cikin sauran wuraren "al'ada" ya fi ƙasa da ƙimar da ake tsammani. Babban abun ciki na gishiri a cikin ruwan famfo shine babban tushen gurɓataccen iska a cikin wanka.

6.Galvanic lalata

A cikin tanki mai kuzari (anodizing ko canza launin electrolytic), tasirin galvanic tsakanin aikin aikin da tanki (tankin karfe), ko tasirin igiyoyin ruwa a cikin tanki mara kuzari (rinsing ko rufewa), na iya haifar da lalata lalatawar rami.

May Jiang ta gyara daga MAT Aluminum

Lokacin aikawa: Dec-15-2023