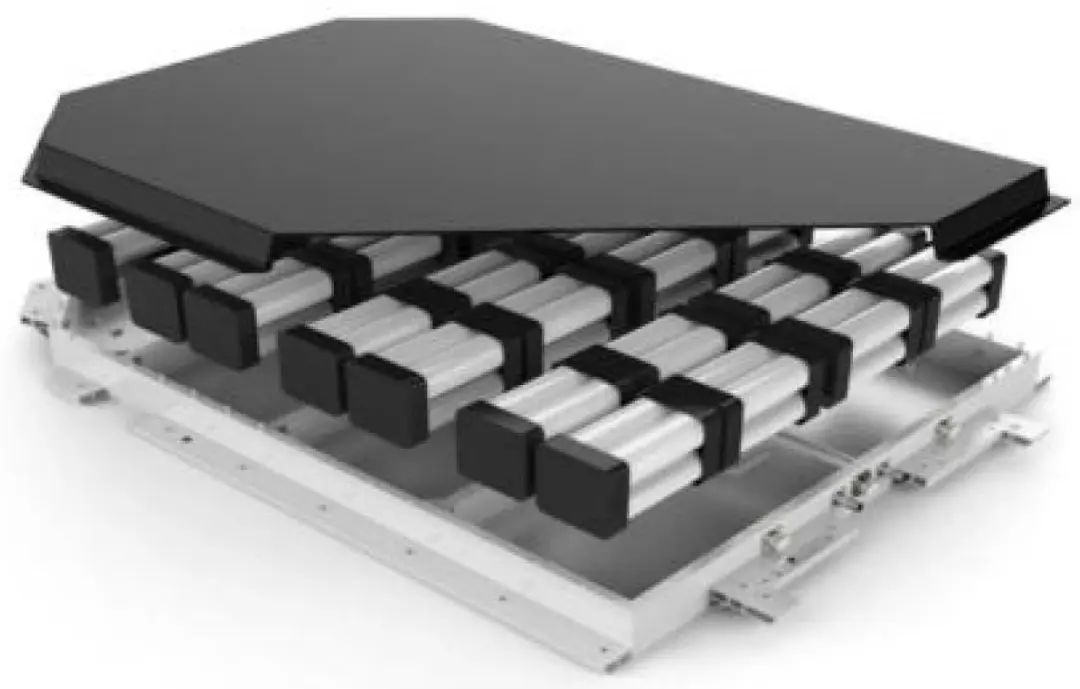

Baturin shine ainihin ɓangaren abin hawa na lantarki, kuma aikinsa yana ƙayyade alamun fasaha kamar rayuwar baturi, yawan kuzari, da rayuwar sabis na motar lantarki. Tireren baturi a cikin tsarin baturi shine babban abin da ke aiwatar da ayyukan ɗauka, karewa, da sanyaya. An shirya fakitin baturi na modular a cikin tiren baturi, an daidaita shi a kan chassis na mota ta hanyar baturin baturi, kamar yadda aka nuna a cikin hoto 1. Tun da yake an shigar da shi a kasan jikin abin hawa kuma yanayin aiki ya kasance mai tsanani, tiren baturi yana buƙatar samun aikin hana tasirin dutse da huda don hana tsarin baturi daga lalacewa. Tireren baturi muhimmin sashi ne na aminci na motocin lantarki. Mai zuwa yana gabatar da tsarin ƙirƙira da ƙirar ƙira na tiren baturin alloy na aluminum don motocin lantarki.

Hoto 1 (Tireren baturi na alloy)

1 Tsarin bincike da ƙirar ƙira

1.1 Binciken simintin gyare-gyare

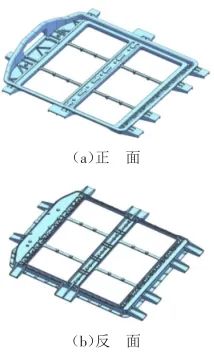

Ana nuna tiren baturi na aluminum alloy don motocin lantarki a cikin Hoto 2. Girman gabaɗaya shine 1106mm × 1029mm × 136mm, kauri na bango na asali shine 4mm, ƙimar simintin yana kusan 15.5kg, kuma ingancin simintin bayan aiki shine kusan 12.5kg. The abu ne A356-T6, tensile ƙarfi ≥ 290MPa, yawan amfanin ƙasa ƙarfi ≥ 225MPa, elongation ≥ 6%, Brinell taurin ≥ 75 ~ 90HBS, bukatar saduwa da iska tightness da IP67 & IP69K bukatun.

Hoto na 2 (Tiren baturi na alloy)

1.2 Binciken tsari

Mutuwar ƙaramin matsi hanya ce ta musamman ta simintin simintin simintin gyare-gyare tsakanin simintin simintin nauyi da simintin nauyi. Ba wai kawai yana da abũbuwan amfãni daga yin amfani da karfe molds ga duka biyu, amma kuma yana da halaye na barga cika. Matsakaicin mutuwar simintin gyare-gyare yana da fa'idodin cikewar ƙarancin sauri daga ƙasa zuwa sama, mai sauƙin sarrafa saurin gudu, ƙaramin tasiri da fantsama na aluminium na ruwa, ƙarancin oxide slag, ƙarancin nama da manyan kaddarorin inji. A karkashin ƙananan matsi na mutu simintin gyare-gyare, ruwan aluminum yana cika sumul, kuma simintin yana ƙarfafawa da crystallizes a ƙarƙashin matsin lamba, kuma ana iya samun simintin tare da babban tsari mai yawa, manyan kayan inji da kyawawan bayyanar, wanda ya dace da kafa manyan simintin gyare-gyare na bakin ciki.

Dangane da kaddarorin injinan da ake buƙata na simintin, kayan simintin shine A356, wanda zai iya biyan bukatun abokan ciniki bayan jiyya na T6, amma yawan ruwan wannan kayan gabaɗaya yana buƙatar kulawa mai ma'ana na ƙirar ƙira don samar da manyan simintin gyare-gyare.

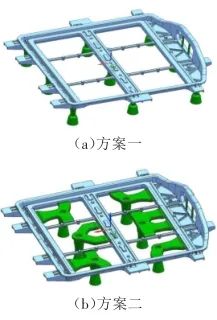

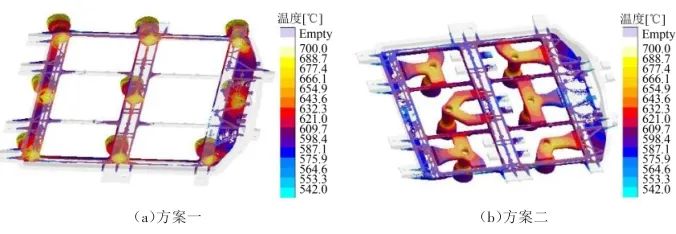

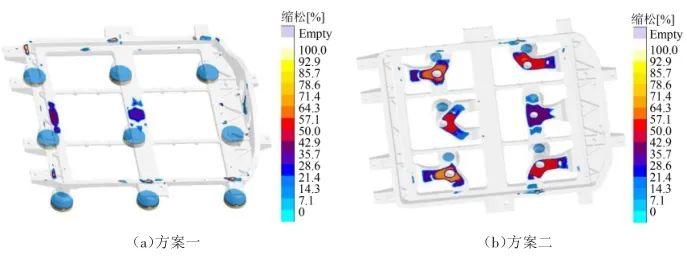

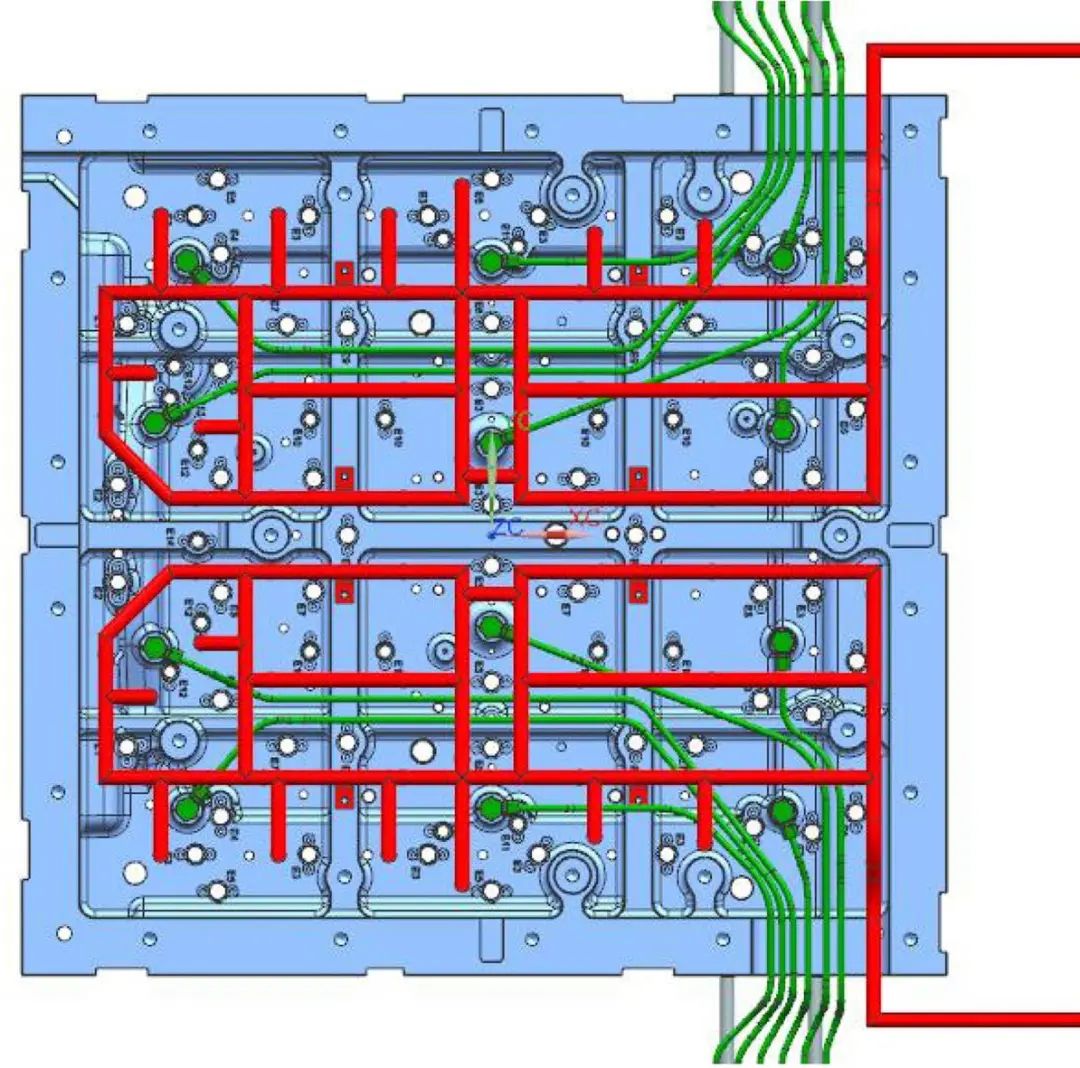

1.3 Tsarin Zuba

Dangane da halaye na simintin gyare-gyare masu girma da na bakin ciki, ana buƙatar tsara ƙofofi da yawa. A lokaci guda, don tabbatar da ingantaccen cikawar ruwa na aluminum, ana ƙara tashoshi masu cikawa a taga, wanda ke buƙatar cirewa ta hanyar aiwatarwa. An tsara tsarin tsari guda biyu na tsarin zubar da ruwa a farkon mataki, kuma an kwatanta kowane makirci. Kamar yadda aka nuna a cikin Hoto na 3, makirci na 1 ya shirya ƙofofi 9 kuma yana ƙara tashoshin ciyarwa a taga; makirci 2 yana shirya kofofi 6 suna zubo daga gefen simintin da za a kafa. Ana nuna nazarin simintin simintin CAE a cikin Hoto na 4 da Hoto 5. Yi amfani da sakamakon simintin don inganta tsarin ƙira, ƙoƙarin guje wa mummunan tasirin ƙirar ƙira akan ingancin simintin gyare-gyare, rage yuwuwar lahani na simintin gyare-gyare, da rage ci gaban ci gaba na simintin gyare-gyare.

Hoto na 3 (kwatanta tsarin tsari guda biyu don ƙananan matsa lamba

Hoto na 4 (kwatancen filin zafin jiki yayin cikawa)

Hoto na 5 (Kwantancin lahani na rashin ƙarfi bayan ƙarfafawa)

Sakamakon kwaikwaiyo na tsare-tsaren biyu na sama sun nuna cewa ruwa na aluminum a cikin rami yana motsawa zuwa sama kusan a layi daya, wanda ya dace da ka'idar daidaitaccen cikawar aluminum ruwa gaba ɗaya, da kuma sassan sassa na simintin gyare-gyare na simintin gyare-gyare ana warware su ta hanyar ƙarfafa sanyaya da sauran hanyoyin.

Amfanin tsare-tsare guda biyu: Yin la'akari da yanayin zafi na aluminum na ruwa yayin cikar siminated, zazzabi na ƙarshen ƙarshen simintin da aka kafa ta hanyar makirci 1 yana da daidaituwa mafi girma fiye da na makirci 2, wanda ke dacewa da cika rami. Simintin gyare-gyaren da aka yi ta tsari na 2 ba shi da ragowar ƙofar kamar makirci 1. Ƙunƙarar ƙaƙƙarfan ƙazamin ya fi na makirci 1.

Lalacewar tsare-tsare guda biyu: Domin an shirya ƙofa akan simintin gyare-gyaren da za a yi a cikin tsarin na 1, za a sami ragowar kofa a kan simintin, wanda zai ƙaru kusan 0.7ka idan aka kwatanta da ainihin simintin. daga zafin jiki na ruwa aluminum a cikin makirci 2 simulated cika, da zafin jiki na ruwa aluminum a m karshen ya riga ya ragu, kuma simulation ne a karkashin manufa yanayin da mold zafin jiki, don haka da kwarara iya aiki na ruwa aluminum iya zama kasa isa a cikin ainihin jihar, kuma za a sami matsala na wahala a simintin gyaran kafa.

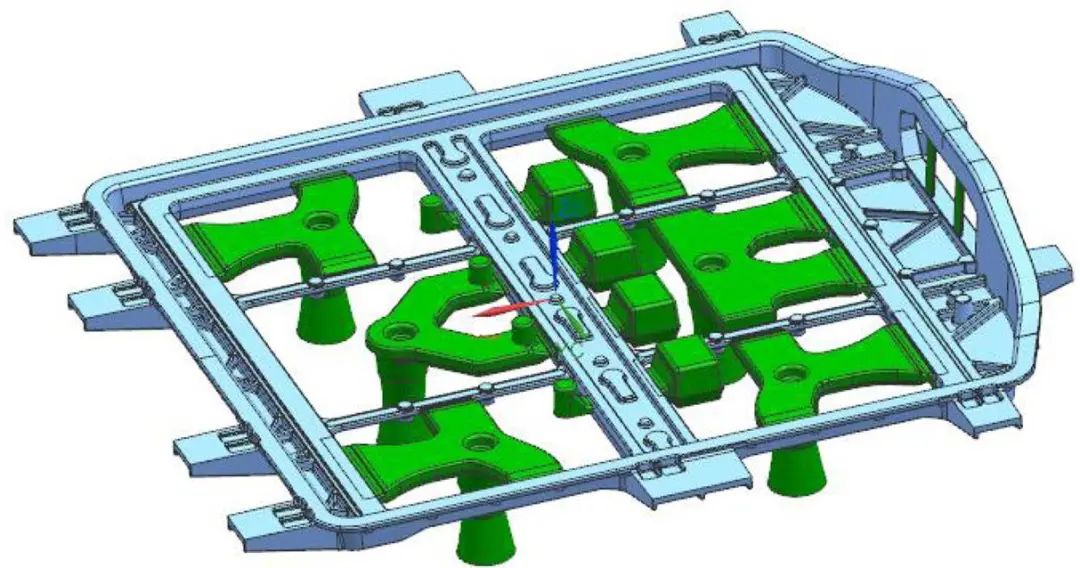

Haɗe tare da nazarin dalilai daban-daban, an zaɓi makirci 2 azaman tsarin zubar da ruwa. Dangane da gazawar makirci na 2, tsarin zubar da ruwa da tsarin dumama an inganta su a cikin ƙirar ƙira. Kamar yadda aka nuna a cikin hoto na 6, an ƙara mai hawan mai ambaliya, wanda ke da fa'ida ga cikowar aluminium mai ruwa kuma yana rage ko guje wa faruwar lahani a cikin simintin gyare-gyare.

Hoto na 6 (Ingantaccen tsarin zubewa)

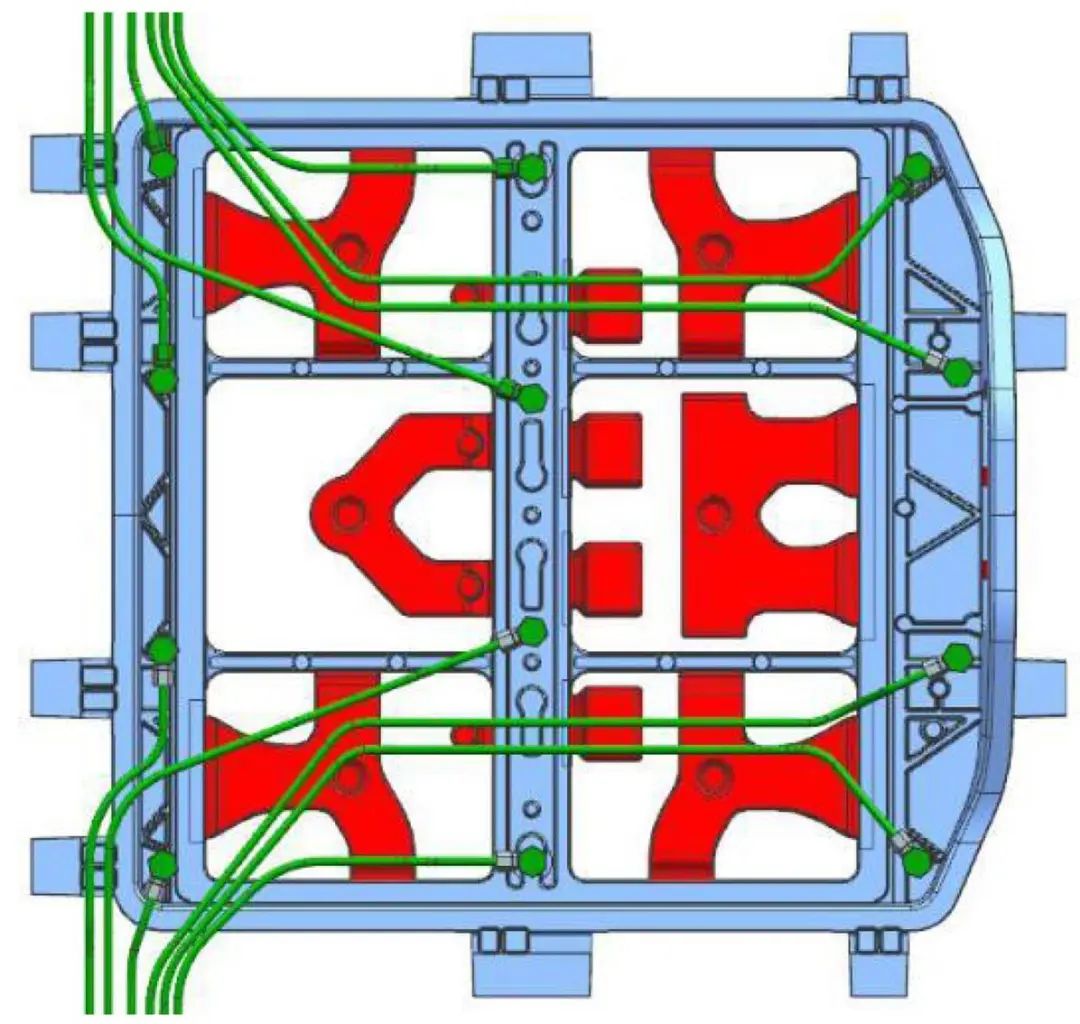

1.4 Tsarin sanyaya

Abubuwan da ke ɗauke da damuwa da wuraren da ke da buƙatun aikin injina na simintin gyare-gyare suna buƙatar a sanyaya su da kyau ko ciyar da su don guje wa raguwar porosity ko fashewar zafi. Asalin kaurin bangon simintin gyare-gyaren shine 4mm, kuma ƙarfafawar za ta yi tasiri ta hanyar zubar da zafi na ƙirar kanta. Don mahimman sassansa, an saita tsarin sanyaya, kamar yadda aka nuna a cikin Hoto na 7. Bayan an gama cikawa, a ba da ruwa don yin sanyi, kuma takamaiman lokacin sanyaya yana buƙatar daidaitawa a wurin da ake zubarwa don tabbatar da cewa an kafa jerin abubuwan ƙarfafawa daga nesa daga ƙarshen ƙofar zuwa ƙarshen ƙofar, kuma ƙofar da riser suna ƙarfafa a ƙarshen don cimma tasirin abinci. Bangaren da ke da kauri mai kauri na bango yana ɗaukar hanyar ƙara sanyaya ruwa zuwa saka. Wannan hanya tana da tasiri mafi kyau a ainihin aikin simintin gyare-gyare kuma zai iya guje wa raguwar porosity.

Hoto na 7 (tsarin sanyaya)

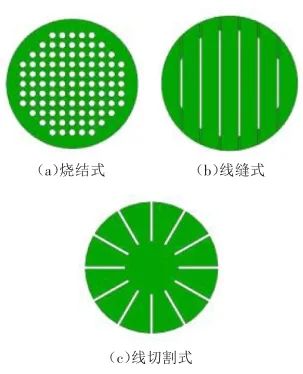

1.5 Tsarin cirewa

Tun da rami na low matsa lamba mutu simintin karfe da aka rufe, shi ba shi da kyau iska permeability kamar yashi molds, kuma bã ya shaye ta risers a general nauyi simintin, da shaye na low-matsa lamba simintin cavity zai shafi ciko aiwatar da ruwa aluminum da kuma ingancin simintin gyaran kafa. The low matsa lamba mutu simintin gyaran kafa za a iya ƙãre ta cikin gibba, shaye tsagi da shaye matosai a cikin rabuwa surface, tura sanda da dai sauransu.

Ƙirar ƙirar ƙira a cikin tsarin shaye-shaye ya kamata ya zama mai dacewa don shayewa ba tare da zubar da ruwa ba, tsarin daɗaɗɗa mai dacewa zai iya hana simintin gyare-gyare daga lahani kamar ƙarancin cikawa, ƙasa mai laushi, da ƙananan ƙarfi. Yankin cikawa na ƙarshe na aluminium na ruwa yayin aikin zubar da ruwa, kamar sauran gefen gefe da mai tashi na ƙera na sama, yana buƙatar sanye take da iskar gas. Dangane da gaskiyar cewa aluminium mai sauƙi yana gudana cikin ratawar filogin shaye-shaye a cikin ainihin aiwatar da ƙarancin matsin lamba mutu simintin, wanda ke haifar da yanayin da ake fitar da toshewar iska lokacin da aka buɗe ƙirar, ana amfani da hanyoyi guda uku bayan yunƙuri da gyare-gyare da yawa: Hanyar 1 tana amfani da toshe foda na ƙarfe na ƙarfe, kamar yadda aka nuna a cikin Hoto 8 (a), rashin lahani shi ne cewa farashin masana'anta yana da yawa; Hanya ta 2 tana amfani da filogi mai nau'in kabu tare da rata na 0.1 mm, kamar yadda aka nuna a cikin hoto 8 (b), rashin amfani shine cewa ana iya toshe kabuwar sharar bayan fesa fenti; Hanya ta 3 tana amfani da filogin shaye-shaye da aka yanke, ratar shine 0.15 ~ 0.2 mm, kamar yadda aka nuna a hoto 8 (c). Abubuwan da ba su da amfani su ne ƙarancin aiki yadda ya dace da tsadar masana'anta. Ana buƙatar zaɓin matosai daban-daban bisa ga ainihin wurin yin simintin. Gabaɗaya, ana amfani da matosai da aka yanke da magudanar huɗa don rami na simintin, kuma ana amfani da nau'in ɗin don saman yashi.

Hoto na 8 (nau'ikan matosai 3 da suka dace da ƙaramin matsa lamba mutu simintin)

1.6 Tsarin dumama

Simintin gyare-gyaren yana da girma a girman kuma sirara a kaurin bango. A cikin bincike na gyare-gyaren ƙirƙira, ƙimar ruwa na aluminum na ruwa a ƙarshen cika bai isa ba. Dalili kuwa shi ne, aluminium ruwa ya yi tsayi da yawa ba zai iya zubowa ba, yanayin zafin jiki ya ragu, kuma ruwan aluminium yana da ƙarfi a gaba kuma ya rasa ƙarfinsa, rufewar sanyi ko rashin isasshen ruwa yana faruwa, mai hawan na sama ba zai iya cimma tasirin ciyarwa ba. Dangane da waɗannan matsalolin, ba tare da canza kauri na bango da siffar simintin gyare-gyare ba, ƙara yawan zafin jiki na aluminium na ruwa da zafin jiki, inganta yanayin ruwa na aluminum, da magance matsalar rufewar sanyi ko rashin isasshen zuba. Duk da haka, yawan zafin jiki na aluminium mai ruwa da zafin jiki zai haifar da sabbin mahaɗar thermal ko raguwar porosity, yana haifar da wuce gona da iri bayan sarrafa simintin gyaran kafa. Sabili da haka, ya zama dole don zaɓar zafin jiki mai dacewa na ruwa na aluminum da zafin jiki mai dacewa. Bisa ga kwarewa, da zazzabi na ruwa aluminum ana sarrafa a game da 720 ℃, da mold zafin jiki ne sarrafawa a 320 ~ 350 ℃.

Dangane da babban girma, kauri na bango na bakin ciki da ƙananan tsayin simintin, an shigar da tsarin dumama a saman ɓangaren ƙirar. Kamar yadda aka nuna a cikin Hoto na 9, alkiblar harshen wuta tana fuskantar ƙasa da gefen ƙirar don dumama jirgin ƙasa da gefen simintin. Dangane da halin da ake ciki a kan shafin yanar gizon, daidaita lokacin dumama da harshen wuta, sarrafa zafin jiki na ɓangaren mold na sama a 320 ~ 350 ℃, tabbatar da ruwa na aluminum na ruwa a cikin kewayon da ya dace, da kuma sanya aluminum aluminum ya cika rami da riser. A cikin ainihin amfani, tsarin dumama zai iya tabbatar da ingancin ruwa na aluminum.

Hoto 9 (Tsarin dumama)

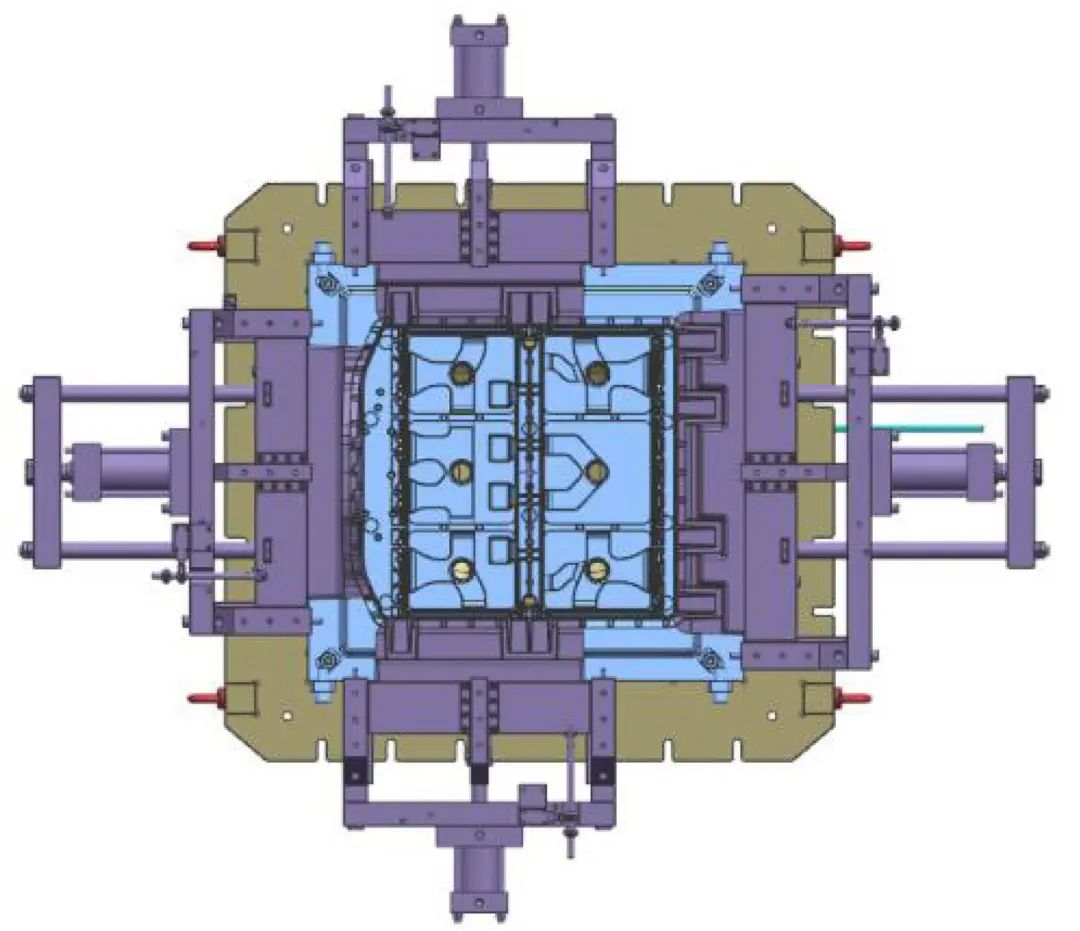

2. Tsarin mold da ka'idar aiki

Bisa ga ƙananan matsa lamba mutu simintin gyare-gyare, haɗe tare da halaye na simintin gyare-gyare da kuma tsarin na kayan aiki, domin tabbatar da cewa kafa simintin gyaran kafa ya tsaya a cikin babba mold, gaba, raya, hagu da dama core-ja Tsarin da aka tsara a kan babba mold. Bayan an samar da simintin gyaran kafa da ƙarfafa, ana buɗe gyare-gyare na sama da na ƙasa da farko, sannan a ja cibiya a cikin kwatance 4, kuma a ƙarshe saman farantin saman na sama yana fitar da simintin da aka kafa. Ana nuna tsarin ƙira a hoto na 10.

Hoto 10 (Tsarin Tsari)

May Jiang ta gyara daga MAT Aluminum

Lokacin aikawa: Mayu-11-2023