Lokacin riƙewa na bayanan bayanan martaba na aluminium an ƙaddara shi ne ta hanyar ingantaccen ƙimar ƙarfin lokaci. A m kudi kudi na ƙarfafa lokaci yana da alaka da quenching zafi zafin jiki, da yanayi na gami, jihar, da sashe girman da aluminum profile, da dumama yanayi, da matsakaici da kuma yawan tanderun loading dalilai.

Lokacin da yawan zafin jiki na gabaɗaya ya karkata zuwa iyakar babba, lokacin riƙe da aluminum ya fi guntu daidai; Bayan babban zafin jiki extrusion, nakasawa digiri ya fi girma, lokacin riƙewa ya fi guntu. Don bayanin martabar aluminium da aka riga aka shafe, saboda lokacin ƙarfafawa yana haɓaka sannu a hankali kuma yana da ƙarfi, ƙimar rushewar lokacin ƙarfafawa yana da hankali, don haka lokacin riƙewa ya fi tsayi daidai.

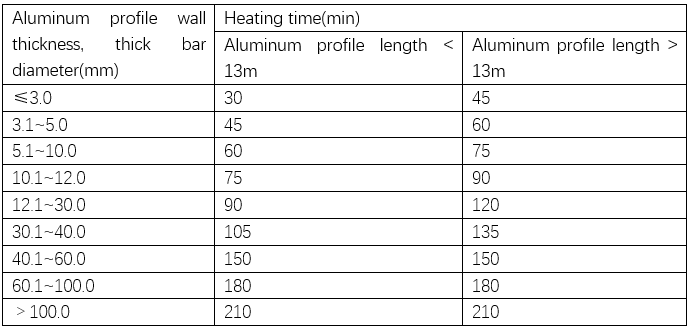

Lokacin riƙe bayanan bayanan aluminum masu zafi a cikin iska mai zafi ya bambanta da na a cikin wanka na gishiri, kuma lokacin dumama a cikin wanka na gishiri ya fi guntu. Yawancin bayanan martaba na masana'antu na aluminum ko sanduna suna amfani da tanderu mai kashe iska a tsaye, kuma ana ƙididdige lokacin riƙewa lokacin da zafin saman ƙarfe ko zafin tanderu ya kai ƙananan iyakar zafin wuta. Tebu na 1 ya lissafa lokutan dumama da riƙon bayanan bayanan aluminum da sanduna masu girma dabam dabam a cikin tanderun da ke kashe iska a tsaye.

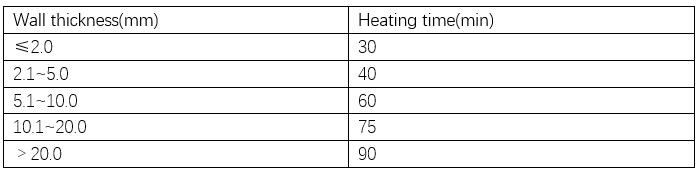

Tebur na 2 yana nuna dumama da riƙe lokacin bututu tare da kaurin bango daban-daban a cikin tanderun da ke kashe iska a tsaye. Lokacin riƙewa na kashe zafi dole ne tabbatar da cewa lokacin ƙarfafawa ya cika cikakke don samun iyakar ƙarfin ƙarfafawa, amma lokacin zafi bai kamata ya yi tsayi da yawa ba, a wasu lokuta, zai rage aikin bayanin martaba.

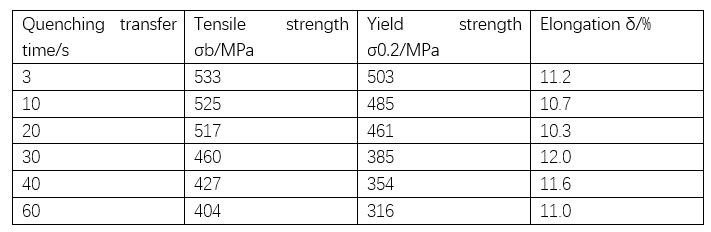

Yawancin bayanan martabar aluminium masu zafi na masana'antu irin su 2A12, 7A04 da sauran bayanan martaba masu ƙarfi ba za a iya kashe su a cikin iska kamar bayanan martaba na aluminum na gine-gine kamar 6063 gami, wato, ƙaramin adadin sanyaya na iya hana hazo na matakan ƙarfafawa. Ana fitar da su daga cikin tanderun zafi mai kashewa, an tura su zuwa tankin ruwa mai kashewa, kuma a sanyaya su cikin iska na ƴan daƙiƙa kaɗan, za a sami hazo na matakan ƙarfafawa, wanda zai shafi tasirin ƙarfafawa. Table 3 ya lissafa tasirin lokutan canja wuri daban-daban na 7A04 alloy akan kayan aikin injiniya bayan quenching.

(Table 3 - 7A04 alloy quenching lokacin canja wurin tasirin akan kayan injin bayanan bayanan aluminum)

Sabili da haka, lokacin canja wuri na quenching yana ɗaya daga cikin sigogin tsari waɗanda dole ne a ƙayyade a cikin tsarin kashe bayanan martaba na aluminum, wato, canja wurin bayanan martaba na aluminum daga tanderun wuta zuwa matsakaicin quenching dole ne a kammala shi a cikin ƙayyadadden lokacin canja wuri, wanda ake kira matsakaicin lokacin canja wuri da aka ba da izini ko lokacin jinkiri. Wannan lokacin yana da alaƙa da abun da ke ciki na haɗin gwiwa, siffar bayanin martaba, da kuma matakin sarrafa kayan aiki na kayan aiki. Idan sharuɗɗa sun yarda, guntun lokacin canja wuri, mafi kyau. Ka'idojin tsari na gabaɗaya: lokacin canja wurin ƙananan bayanan martaba bai kamata ya wuce 20s ba, manyan ko batch quenched aluminum profiles kada ya wuce 40s; don manyan bayanan martaba kamar 7A04, lokacin canja wuri bai kamata ya wuce 15s ba.

May Jiang ta gyara daga MAT Aluminum

Lokacin aikawa: Oktoba-21-2023