Gabatarwa

Tare da haɓaka masana'antar kera motoci, kasuwa don tasirin tasirin tasirin aluminum shima yana haɓaka cikin sauri, kodayake har yanzu ƙanƙanta a cikin girman gabaɗaya. Dangane da hasashen da Ƙungiyar Ƙirƙirar Fasaha ta Fasaha ta Fasaha ta Automotive Lightweight Technology don kasuwar tasirin katako ta aluminum na kasar Sin, ya nuna cewa nan da shekarar 2025, an kiyasta bukatar kasuwa ta kai tan 140,000, tare da girman kasuwar da ake sa ran zai kai RMB biliyan 4.8. Nan da shekarar 2030, ana hasashen bukatar kasuwar za ta kai tan 220,000, tare da kiyasin girman kasuwar da ya kai RMB biliyan 7.7, da adadin karuwar shekara-shekara na kusan kashi 13%. Haɓaka haɓakar haɓakar nauyi da saurin haɓakar samfuran abin hawa na tsakiyar zuwa-ƙarshe sune mahimman abubuwan tuƙi don haɓaka tasirin tasirin aluminum a cikin Sin. Hasashen kasuwa don tasirin tasirin katako na hadarurruka suna da alƙawarin.

Yayin da farashin ke raguwa da ci gaban fasaha, ginshiƙan alloy na gaban tasirin aluminum da akwatunan haɗari suna ƙara yaɗuwa a hankali. A halin yanzu, ana amfani da su a cikin nau'ikan abin hawa na tsakiyar-zuwa-ƙarshe kamar Audi A3, Audi A4L, jerin BMW 3, BMW X1, Mercedes-Benz C260, Honda CR-V, Toyota RAV4, Buick Regal, da Buick LaCrosse.

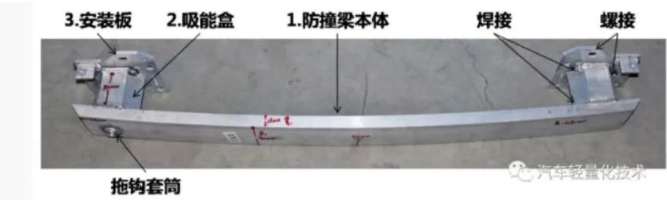

Ƙwayoyin tasiri na Aluminum sun haɗa da tasiri na giciye, akwatunan haɗari, hawa baseplates, da kuma hannun rigar ƙugiya, kamar yadda aka nuna a hoto 1.

Hoto 1: Aluminum Alloy Impact Beam Assembly

Akwatin hadarin akwatin karfe ne da ke tsakanin katako mai tasiri da igiyoyin tsayi biyu na abin hawa, da gaske suna aiki azaman akwati mai ɗaukar kuzari. Wannan makamashi yana nufin ƙarfin tasiri. Lokacin da abin hawa ya fuskanci karo, tasirin tasirin yana da wani matakin iya ɗaukar kuzari. Koyaya, idan makamashin ya wuce ƙarfin tasirin tasirin, zai canza kuzarin zuwa akwatin hatsarin. Akwatin hatsarin yana ɗaukar duk ƙarfin tasiri kuma yana lalata kansa, yana tabbatar da cewa ƙullun na tsaye ba su lalace ba.

1 Bukatun samfur

1.1 Girma dole ne su bi ka'idodin haƙuri na zane, kamar yadda aka nuna a hoto 2.

1.3 Bukatun Ayyukan Injini:

Ƙarfin Ƙarfin Ƙarfi: ≥215 MPa

Ƙarfin Haɓaka: ≥205 MPa

Tsawaita A50: ≥10%

1.4 Aiki Crash Box:

Tare da X-axis na abin hawa, ta yin amfani da farfajiyar karo mafi girma fiye da sashin giciye na samfurin, lodi a gudun 100 mm/min har sai an murkushe, tare da matsa lamba na 70%. Tsawon farko na bayanin martaba shine 300 mm. A mahaɗin haƙarƙarin ƙarfafawa da bangon waje, tsagewar ya kamata ya zama ƙasa da mm 15 don a ɗauka karɓuwa. Ya kamata a tabbatar da cewa fashewar da aka ba da izini ba ta yin lahani ga murkushe bayanan martabar ƙarfin ɗaukar kuzari, kuma kada a sami faɗuwar fage a wasu wurare bayan murkushe su.

2 Hanyar Ci gaba

Don saduwa da buƙatun aikin injiniya lokaci guda da aikin murƙushewa, tsarin haɓakawa shine kamar haka:

Yi amfani da sandar 6063B tare da haɗin gwal na farko na Si 0.38-0.41% da Mg 0.53-0.60%.

Yi quenching iska da tsufa na wucin gadi don cimma yanayin T6.

Yi amfani da hazo + kashe iska da gudanar da maganin tsufa don cimma yanayin T7.

3 Samar da Jirgin Sama

3.1 Yanayin Extrusion

Ana aiwatar da samarwa akan 2000T extrusion press tare da wani extrusion rabo na 36. Kayan da aka yi amfani da shi ne homogenized aluminum sanda 6063B. The dumama yanayin zafi na aluminum sanda ne kamar haka: IV zone 450-III zone 470-II zone 490-1 zone 500. Babban Silinda ta nasara matsa lamba ne a kusa da 210 mashaya, tare da barga extrusion lokaci da ciwon extrusion matsa lamba kusa da 180 bar. Gudun shaft ɗin extrusion shine 2.5 mm / s, kuma saurin extrusion bayanin martaba shine 5.3 m / min. Zazzabi a wurin fitarwa shine 500-540 ° C. Ana yin quenching ta amfani da sanyaya iska tare da ikon fan na hagu a 100%, ikon fan na tsakiya a 100%, da ikon fan dama a 50%. Matsakaicin yanayin sanyaya a cikin yankin quenching ya kai 300-350 ° C/min, kuma zafin jiki bayan barin yankin quenching shine 60-180 ° C. Don hazo + iska quenching, matsakaicin yawan sanyaya a cikin yankin dumama ya kai 430-480 ° C/min, kuma zafin jiki bayan barin yankin quenching shine 50-70 ° C. Bayanan martaba ba ya nuna wani muhimmin lanƙwasa.

3.2 Tsufa

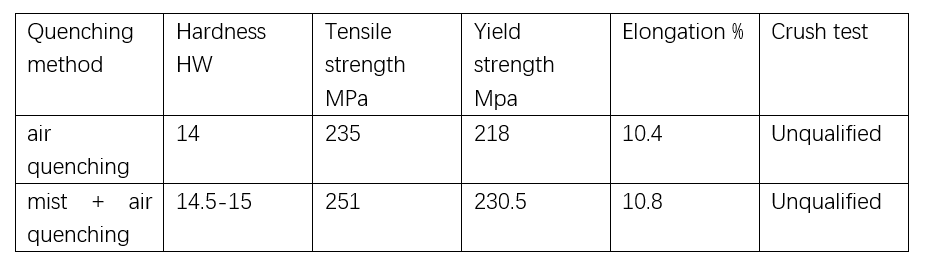

Bayan tsarin tsufa na T6 a 185 ° C na tsawon sa'o'i 6, taurin kayan da kayan aikin injiniya sune kamar haka:

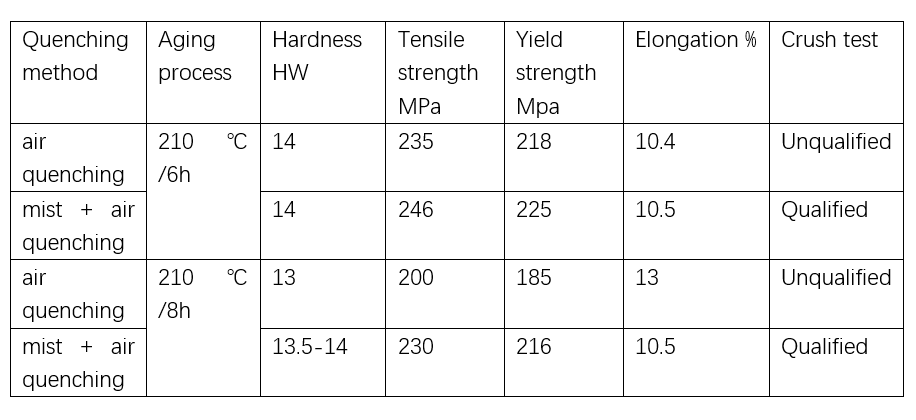

Dangane da tsarin tsufa na T7 a 210 ° C na sa'o'i 6 da sa'o'i 8, taurin kayan da kayan aikin injiniya sune kamar haka:

Dangane da bayanan gwajin, hazo + hanyar kashe iska, haɗe tare da tsarin tsufa na 210 ° C / 6h, ya cika buƙatun duka aikin injiniya da gwajin murkushewa. Idan aka yi la'akari da ingancin farashi, hazo + hanyar kashe iska da tsarin tsufa na 210°C/6h an zaɓi don samarwa don biyan buƙatun samfurin.

3.3 Gwajin murƙushewa

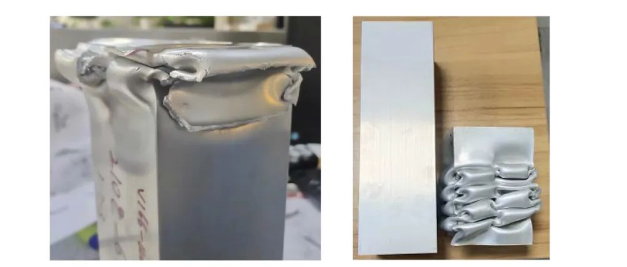

Don sanduna na biyu da na uku, an yanke ƙarshen kai da 1.5m, kuma an yanke wutsiya ta 1.2m. Ana ɗaukar samfurori guda biyu kowanne daga sassan kai, tsakiya, da wutsiya, tare da tsawon 300mm. Ana gudanar da gwaje-gwajen murkushewa bayan tsufa a 185 ° C / 6h da 210 ° C / 6h da 8h (bayanan aikin injiniya kamar yadda aka ambata a sama) akan injin gwajin kayan duniya. Ana gudanar da gwaje-gwaje a cikin saurin lodi na 100 mm / min tare da adadin matsawa na 70%. Sakamakon shine kamar haka: don hazo + iska tare da tsarin tsufa na 210 ° C / 6h da 8h, gwaje-gwajen murkushewa sun cika buƙatun, kamar yadda aka nuna a cikin Hoto 3-2, yayin da samfurin da aka kashe da iska yana nuna fashewa ga duk matakan tsufa.

Dangane da sakamakon gwajin murkushe, hazo + iska mai kashewa tare da matakan tsufa na 210°C/6h da 8h sun cika buƙatun abokin ciniki.

4 Kammalawa

Haɓaka matakan kashewa da tsufa yana da mahimmanci don ci gaban samfur mai nasara kuma yana ba da ingantaccen tsari don samfurin akwatin hatsari.

Ta hanyar m gwaji, an ƙaddara cewa abu jihar ga hadarin akwatin samfurin ya zama 6063-T7, da quenching Hanyar ne hazo + iska sanyaya, da kuma tsufa tsari a 210 ° C / 6h ne mafi kyau zabi ga extruding aluminum sanduna da yanayin zafi jere daga 480-500 ° C, extrusion shaft mutuwa da zafin jiki na 2.5 ° C, da kuma extrusion shaft gudun na 2.5 ° C. zafin jiki na extrusion na 500-540 ° C.

May Jiang ta gyara daga MAT Aluminum

Lokacin aikawa: Mayu-07-2024