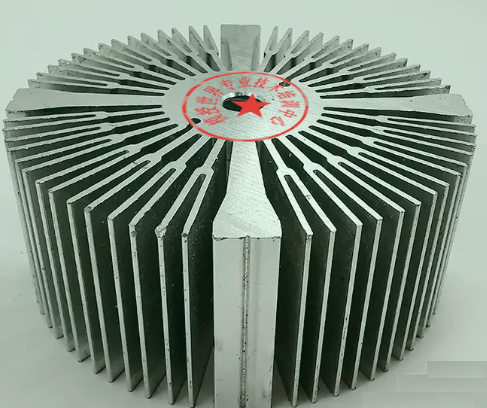

Saboda aluminium alloys suna da nauyi, masu kyau, suna da juriya mai kyau, kuma suna da kyakkyawan yanayin zafin jiki da aikin sarrafawa, ana amfani da su sosai azaman abubuwan haɓaka zafi a cikin masana'antar IT, kayan lantarki da masana'antar kera motoci, musamman a cikin masana'antar LED da ke tasowa a halin yanzu. Wadannan abubuwan da aka haɗar da wutar lantarki na aluminium suna da ayyuka masu kyau na zafi. A cikin samarwa, mabuɗin don ingantacciyar haɓakar haɓakar waɗannan bayanan bayanan radiyo shine mold. Domin wadannan bayanan martaba kullum suna da halaye na manyan da kuma m zafi dissipation hakora da kuma dogon dakatar shambura, gargajiya lebur mutu tsarin, tsaga mutu tsarin da Semi-m profile mutu tsarin ba zai iya da kyau hadu da bukatun na mold ƙarfi da extrusion gyare-gyare.

A halin yanzu, masana'antu sun fi dogara ga ingancin ƙura. Don inganta ƙarfin ƙura, ba sa jinkirin yin amfani da ƙarfe mai tsada daga waje. Farashin gyare-gyaren yana da yawa, kuma ainihin matsakaicin rayuwa na mold ɗin bai wuce 3t ba, wanda ya haifar da farashin kasuwa na radiyo yana da tsayi sosai, yana hana haɓakawa da kuma yada fitilun LED. Saboda haka, extrusion ya mutu don bayanin martabar radiyo mai siffar sunflower sun jawo hankali sosai daga aikin injiniya da ma'aikatan fasaha a cikin masana'antu.

Wannan labarin yana gabatar da fasahohi daban-daban na bayanan bayanan martaba na sunflower extrusion wanda aka samu ta tsawon shekaru na bincike mai ɗorewa da kuma maimaita gwajin gwaji ta hanyar misalai a cikin samarwa na ainihi, don tunani ta hanyar takwarorinsu.

1. Binciken halayen tsarin sassan bayanan martaba na aluminum

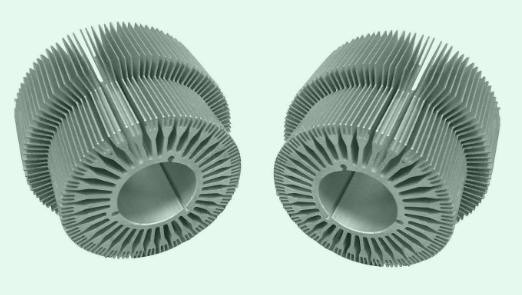

Hoto na 1 yana nuna ɓangaren giciye na bayanin martabar aluminum sunflower na yau da kullun. Yankin giciye na bayanin martaba shine 7773.5mm², tare da jimlar 40 haƙoran zubar da zafi. Matsakaicin girman buɗewar rataye da aka kafa tsakanin haƙora shine 4.46 mm. Bayan lissafi, rabon harshe tsakanin hakora shine 15.7. A lokaci guda, akwai babban yanki mai ƙarfi a tsakiyar bayanan martaba, tare da yanki na 3846.5mm².

Yin la'akari da sifofin sifofi na bayanin martaba, sararin samaniya tsakanin hakora za a iya la'akari da shi azaman bayanan martaba mai zurfi, kuma bayanin martabar radiyo ya ƙunshi bayanan martaba masu yawa. Sabili da haka, lokacin zayyana tsarin ƙirar, maɓalli shine la'akari da yadda ake tabbatar da ƙarfin ƙirar. Ko da yake ga Semi-m profiles, da masana'antu ya ɓullo da wani iri-iri balagagge mold Tsarin, kamar "rufe splitter mold", "yanke splitter mold", "dakatar gada splitter mold", da dai sauransu Duk da haka, wadannan Tsarin ba m zuwa kayayyakin hada da mahara Semi-m profiles. Tsarin al'ada yana la'akari da kayan kawai, amma a cikin gyare-gyaren extrusion, mafi girman tasiri akan ƙarfi shine ƙarfin extrusion yayin aikin extrusion, kuma tsarin ƙirar ƙarfe shine babban abin da ke haifar da ƙarfin extrusion.

Saboda babban babban yanki mai ƙarfi na bayanin martaba na hasken rana, yana da sauƙi sosai don haifar da yawan kwararar ruwa a cikin wannan yanki da sauri yayin aiwatar da extrusion, kuma ƙarin damuwa mai ƙarfi za a haifar da shi a kan bututun dakatarwar intertooth, wanda zai haifar da karyewar bututun dakatarwar intertooth. Saboda haka, a cikin zane na mold tsarin, ya kamata mu mayar da hankali a kan daidaita da karfe kwarara kudi da kuma kwarara kudi don cimma manufar rage extrusion matsa lamba da kuma inganta danniya yanayin da dakatar da bututu tsakanin hakora, don inganta ƙarfin mold.

2. Zaɓin tsarin ƙira da ƙarfin latsawa na extrusion

2.1 Tsarin tsari na Mold

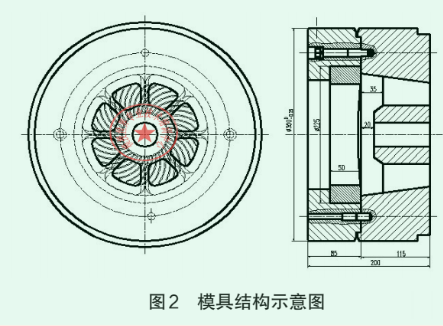

Don bayanin martabar radiyo na sunflower da aka nuna a cikin Hoto 1, kodayake ba shi da wani yanki mai zurfi, dole ne ya ɗauki tsarin tsaga kamar yadda aka nuna a cikin Hoto 2. Bambanci da tsarin shunt na gargajiya na gargajiya, an sanya ɗakin tashar sayar da ƙarfe a cikin mold na sama, kuma ana amfani da tsarin sakawa a cikin ƙananan mold. Manufar ita ce don rage farashin mold da rage sake zagayowar masana'anta. Dukansu na sama da ƙananan gyare-gyaren gyare-gyare na duniya ne kuma ana iya sake amfani da su. Mafi mahimmanci, ana iya sarrafa ɓangarorin ramin mutuwa da kansa, wanda zai iya tabbatar da daidaiton bel ɗin aikin rami na mutu. An tsara rami na ciki na ƙananan ƙira a matsayin mataki. Babban ɓangaren da kuma toshe rami mai ƙyalƙyali yana ɗaukar yarda dacewa, kuma ƙimar tazara a bangarorin biyu shine 0.06 ~ 0.1m; ƙananan ɓangaren yana ɗaukar tsangwama mai dacewa, kuma adadin tsangwama a bangarorin biyu shine 0.02 ~ 0.04m, wanda ke taimakawa tabbatar da haɗin kai da kuma sauƙaƙe taro, yana sa inlay ɗin ya fi dacewa, kuma a lokaci guda, zai iya guje wa lalacewar ƙwayar cuta ta hanyar tsoma baki ta thermal shigarwa.

2.2 Zaɓin ƙarfin extruder

Zaɓin zaɓin ƙarfin fitarwa shine, a gefe guda, don ƙayyade diamita mai dacewa na ciki na ganga mai fitarwa da matsakaicin ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun kayan aiki don saduwa da matsa lamba a lokacin samar da karfe. A daya hannun, shi ne don ƙayyade dace extrusion rabo da kuma zaži dace mold size bayani dalla-dalla dangane da kudin. Don bayanin martabar aluminum na sunflower radiator, rabon extrusion ba zai iya zama babba ba. Babban dalili shi ne cewa ƙarfin extrusion yana daidai da rabo na extrusion. Mafi girman rabon extrusion, mafi girman ƙarfin extrusion. Wannan yana da matuƙar cutarwa ga ƙirar bayanin martabar aluminum na sunflower.

Kwarewar ta nuna cewa ƙimar extrusion na bayanan martaba na aluminum don radiators sunflower bai wuce 25. Don bayanin martabar da aka nuna a cikin Hoto 1, an zaɓi 20.0 MN extruder tare da diamita na ciki na extrusion ganga na 208 mm. Bayan lissafi, matsakaicin takamaiman matsa lamba na extruder shine 589MPa, wanda shine ƙimar da ta dace. Idan ƙayyadadden matsa lamba ya yi yawa, matsa lamba akan ƙirar zai zama babba, wanda ke da lahani ga rayuwar ƙirar; idan takamaiman matsa lamba ya yi ƙasa da ƙasa, ba zai iya biyan buƙatun ƙirƙirar extrusion ba. Experiencewarewa ya nuna cewa takamaiman matsa lamba a cikin kewayon 550 ~ 750 MPa na iya mafi kyawun biyan buƙatun tsari daban-daban. Bayan lissafi, da extrusion coefficient ne 4.37. An zaɓi ƙayyadaddun girman ƙira a matsayin 350 mmx200 mm (diamita na waje x digiri).

3. Ƙayyadaddun sigogi na tsari na mold

3.1 Babban mold tsarin sigogi

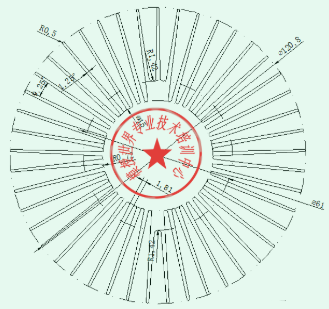

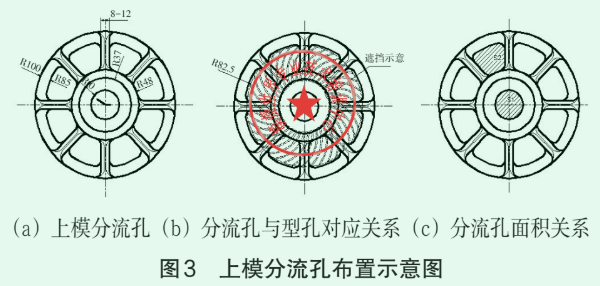

(1) Lamba da tsari na ramukan karkata. Don bayanin martabar sunflower shunt mold, yawan adadin ramukan shunt, mafi kyau. Don bayanan martaba masu siffofi masu kama da madauwari, 3 zuwa 4 ramukan shunt na gargajiya gabaɗaya ana zaɓin su. Sakamakon shi ne cewa nisa na shunt gada ya fi girma. Gabaɗaya, lokacin da ya fi girma fiye da 20mm, adadin weld ɗin ya ragu. Koyaya, lokacin zabar bel ɗin aiki na ramin mutuwa, bel ɗin aiki na ramin mutuwa a ƙasan gadar shunt dole ne ya zama ya fi guntu. A karkashin yanayin cewa babu daidaitattun hanyar ƙididdigewa don zaɓin bel ɗin aiki, zai iya haifar da ramin mutuwa a ƙarƙashin gada da sauran sassa don ba za a cimma daidai adadin kwararar ruwa ba yayin extrusion saboda bambanci a cikin bel ɗin aiki, Wannan bambance-bambance a cikin ƙimar kwarara zai haifar da ƙarin damuwa mai ƙarfi akan cantilever kuma yana haifar da karkatar da haƙoran zafi. Don haka, don extrusion na sunflower sun mutu tare da adadi mai yawa na hakora, yana da matukar mahimmanci don tabbatar da cewa yawan kwararar kowane hakori ya daidaita. Yayin da adadin ramukan shunt ya karu, adadin gadojin shunt zai karu daidai da haka, kuma yawan kwararar ruwa da rarrabawar karfe zai zama mafi girma. Wannan saboda yayin da adadin gadar shunt ya karu, za a iya rage nisa na gadojin shunt daidai.

Bayanai masu amfani sun nuna cewa adadin ramukan shunt gabaɗaya 6 ko 8 ne, ko ma fiye da haka. Tabbas, don wasu manyan bayanan bayanan zafi na sunflower, ƙirar babba kuma na iya shirya ramukan shunt bisa ga ka'idar shunt gada nisa ≤ 14mm. Bambanci shine cewa dole ne a ƙara faranti na gaba don rarrabawa da daidaita ƙarfin ƙarfe. Lamba da tsari na ramukan karkatarwa a cikin faranti na gaba za a iya aiwatar da su ta hanyar gargajiya.

Bugu da ƙari, lokacin shirya ramukan shunt, ya kamata a yi la'akari da yin amfani da mold na sama don dacewa da kariya ga shugaban cantilever na hakoran zafi don hana karfe daga kai tsaye ya buga kan tube na cantilever kuma don haka inganta yanayin damuwa na cantilever tube. Sashin da aka toshe na cantilever kan tsakanin hakora zai iya zama 1/5 ~ 1/4 na tsawon bututun cantilever. Ana nuna shimfidar ramukan shunt a hoto na 3

(2) Alakar yanki na shunt rami. Domin kaurin bangon tushen hakorin zafi kadan ne kuma tsayinsa ya yi nisa da tsakiya, kuma bangaren zahiri ya sha bamban da na tsakiya, shi ne mafi wahala wajen samar da karfe. Sabili da haka, mahimmin mahimmanci a cikin ƙirar ƙirar bayanin martabar sunflower shine don sanya yawan kwararar sashin tsakiya a hankali a hankali don tabbatar da cewa ƙarfe ya fara cika tushen hakori. Don cimma irin wannan sakamako, a gefe guda, shine zaɓi na bel ɗin aiki, kuma mafi mahimmanci, ƙaddarar yanki na rami mai karkatarwa, yawanci yankin tsakiya wanda ya dace da rami mai karkatarwa. Gwaje-gwaje da ƙididdige ƙididdigewa sun nuna cewa an sami sakamako mafi kyau lokacin da yanki na tsakiya na tsakiya S1 da kuma yanki na waje guda S2 ramin diverter S2 ya gamsar da dangantaka mai zuwa: S1 = (0.52 ~ 0.72) S2

Bugu da ƙari, tashar tashar ƙarfe mai tasiri mai mahimmanci na ramin tsaga na tsakiya ya kamata ya zama 20 ~ 25mm ya fi tsayi fiye da tashar wutar lantarki mai mahimmanci na ramin tsaga na waje. Wannan tsayin yana kuma la'akari da gefe da yiwuwar gyaran gyare-gyare.

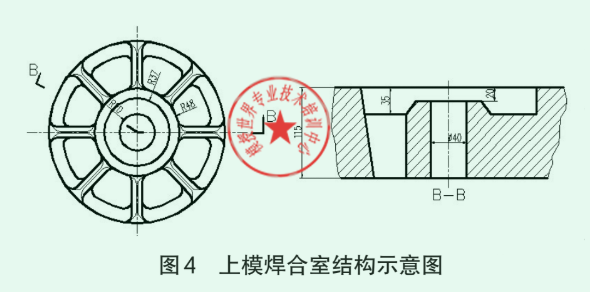

(3) Zurfin dakin walda. Mutuwar bayanin martabar sunflower radiyo ya bambanta da mutuwar shunt na gargajiya. Duk ɗakin walda ɗin sa dole ne ya kasance a cikin babban mutu. Wannan shine don tabbatar da daidaiton aikin toshe rami na ƙananan mutu, musamman madaidaicin bel ɗin aiki. Idan aka kwatanta da na gargajiya shunt mold, zurfin dakin walda na Sunflower profile shunt mold yana buƙatar ƙarawa. Mafi girman ƙarfin injin extrusion, haɓaka mafi girma a cikin zurfin ɗakin walda, wanda shine 15 ~ 25mm. Misali, idan an yi amfani da injin extrusion 20 MN, zurfin ɗakin walda na shunt ɗin gargajiya shine 20 ~ 22mm, yayin da zurfin ɗakin walda na shunt ya mutu na bayanin martabar sunflower ya kamata ya zama 35 ~ 40 mm. Amfanin wannan shine cewa karfe yana da cikakkiyar walƙiya kuma damuwa akan bututun da aka dakatar yana raguwa sosai. Ana nuna tsarin ɗakin waldawar ƙera na sama a hoto na 4.

3.2 Zane na saka ramin mutu

Zane-zanen toshe rami mai mutuƙar ya haɗa da girman rami mai mutu, bel ɗin aiki, diamita na waje da kauri na toshe madubi, da sauransu.

(1) Tabbatar da girman ramin mutu. Za a iya ƙayyade girman ramin mutuwa ta hanyar gargajiya, musamman la'akari da sikelin sarrafa zafin jiki na gami.

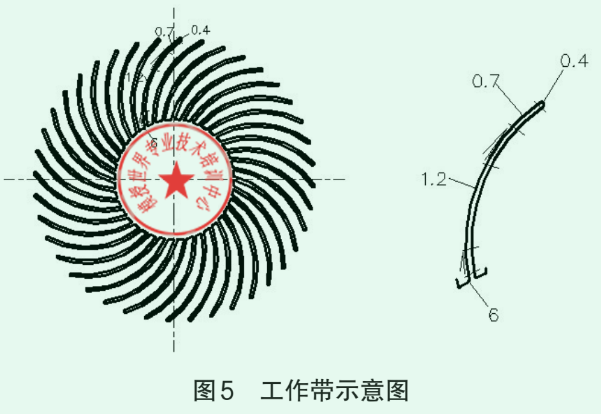

(2) Zaɓin bel ɗin aiki. Ka'idar zaɓin bel ɗin aiki shine a fara tabbatar da cewa samar da duk ƙarfe a kasan tushen hakori ya isa, ta yadda yawan kwararar da ke ƙasan tushen hakori ya fi sauran sassa sauri. Sabili da haka, bel ɗin aiki a kasan tushen hakori ya kamata ya zama mafi guntu, tare da darajar 0.3 ~ 0.6mm, kuma bel ɗin aiki a sassan da ke kusa ya kamata a ƙara da 0.3mm. Ka'idar ita ce haɓaka ta 0.4 ~ 0.5 kowane 10 ~ 15mm zuwa cibiyar; Abu na biyu, bel ɗin aiki a mafi girman ƙaƙƙarfan ɓangaren cibiyar bai kamata ya wuce 7mm ba. In ba haka ba, idan tsayin tsayin bel ɗin aiki ya yi girma, manyan kurakurai za su faru a cikin sarrafa na'urorin jan ƙarfe da sarrafa EDM na bel ɗin aiki. Wannan kuskuren na iya haifar da jujjuyawar haƙori cikin sauƙi yayin aikin fitar da haƙori. Ana nuna bel ɗin aiki a hoto na 5.

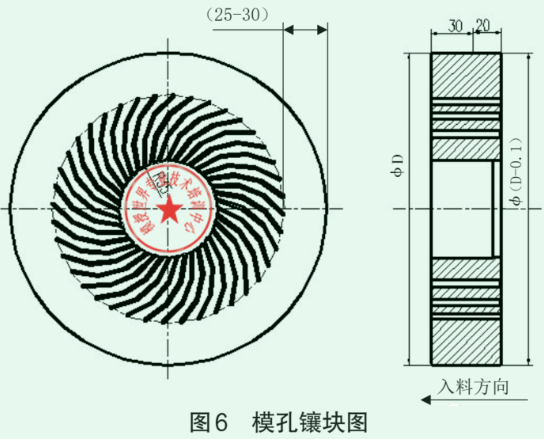

(3) Diamita na waje da kauri na abin da aka saka. Don gyare-gyaren shunt na gargajiya, kauri na rami rami shine kauri na ƙananan mold. Koyaya, don ƙirar radiyon sunflower, idan kauri mai tasiri na ramin mutu ya yi girma, bayanin martaba zai iya yin karo da ƙirar a sauƙaƙe yayin fitarwa da fitarwa, yana haifar da rashin daidaituwar haƙora, ɓarna ko ma haƙori. Wadannan zasu sa hakora su karye.

Bugu da ƙari, idan kaurin ramin mutu ya yi tsayi da yawa, a gefe guda, lokacin sarrafawa yana da tsawo a lokacin aikin EDM, kuma a gefe guda, yana da sauƙi don haifar da lalatawar lantarki, kuma yana da sauƙi don haifar da haƙori yayin extrusion. Tabbas, idan kauri ramin mutu yayi ƙanƙanta, ƙarfin haƙora ba zai iya tabbatarwa ba. Saboda haka, yin la'akari da waɗannan abubuwa guda biyu, ƙwarewa ya nuna cewa ramin ramin mutuwa na ƙananan mold shine gaba ɗaya 40 zuwa 50; kuma diamita na waje na saka rami mai mutu ya kamata ya zama 25 zuwa 30 mm daga mafi girman gefen ramin mutuwa zuwa da'irar waje na saka.

Don bayanin martaba da aka nuna a Hoto 1, diamita na waje da kauri na toshe ramin mutuwa sune 225mm da 50mm bi da bi. An nuna saka rami mai mutu a cikin hoto na 6. D a cikin adadi shine ainihin girman kuma girman ƙididdiga shine 225mm. Matsakaicin ƙayyadaddun girman girmansa yana daidaita daidai da ramin ciki na ƙananan ƙirar don tabbatar da cewa tazarar ɗaya ta kasance tsakanin kewayon 0.01 ~ 0.02mm. An nuna toshe rami mai mutu a cikin Hoto na 6. Girman ƙididdiga na ramin ciki na toshe ramin mutuwar da aka sanya akan ƙananan ƙirar shine 225mm. Dangane da girman ma'auni na ainihi, toshe ramin mutuwar ya dace daidai da ka'idar 0.01 ~ 0.02mm a kowane gefe. Za a iya samun diamita na waje na toshe rami mai mutu a matsayin D , amma don dacewa da shigarwa, za a iya rage girman diamita na diamita na ramin ramin madubi da kyau a cikin kewayon 0.1m a ƙarshen ciyarwa, kamar yadda aka nuna a cikin adadi.

4. Maɓalli na fasaha na ƙirar ƙira

Mashin ɗin gyare-gyaren bayanin martaba na Sunflower ba shi da bambanci da na na yau da kullun na bayanin martaba na aluminum. Bambancin bayyane yana nunawa a cikin sarrafa wutar lantarki.

(1) Dangane da yankan waya, wajibi ne a hana nakasar na’urar lantarki ta tagulla. Domin wutar lantarkin tagulla da ake amfani da ita don EDM suna da nauyi, haƙora sun yi ƙanƙanta, wutar lantarki da kanta tana da laushi, ba ta da ƙarfi sosai, kuma yanayin zafi na gida da ake samu ta hanyar yankan waya yana sa wutar lantarki ta zama cikin sauƙi a lokacin aikin yanke waya. Lokacin amfani da gurɓatattun na'urorin lantarki na jan ƙarfe don sarrafa bel ɗin aiki da wuƙaƙe maras amfani, haƙoran da ba su da kyau za su faru, wanda zai iya haifar da ɓarke da sauƙi yayin sarrafawa. Sabili da haka, ya zama dole don hana nakasar na'urorin lantarki na jan karfe yayin aikin masana'antar kan layi. Babban matakan rigakafi sune: kafin yanke waya, daidaita shingen tagulla tare da gado; yi amfani da alamar bugun kira don daidaita tsaye a farkon; Lokacin yankan waya, fara daga sashin hakori da farko, sannan a yanke sashin da bango mai kauri; Kowane lokaci a cikin ɗan lokaci, yi amfani da wariyar azurfa don cika sassan da aka yanke; bayan an yi waya, sai a yi amfani da injin waya don yanke wani ɗan gajeren sashe na kusan mm 4 tare da tsayin da aka yanke na jan ƙarfe.

(2) Injin fitar da wutar lantarki a fili ya bambanta da na yau da kullun. EDM yana da matukar muhimmanci a cikin sarrafa kayan aikin radiyo na sunflower. Ko da zane ya kasance cikakke, ƙananan lahani a cikin EDM zai haifar da kullun da aka lalata. Injin fitar da wutar lantarki baya dogaro da kayan aiki kamar yankan waya. Ya dogara da yawa akan ƙwarewar aiki da ƙwarewar ma'aikacin. Injin fitar da wutar lantarki ya fi mai da hankali ga abubuwa biyar masu zuwa:

①Machining na fitar da wutar lantarki. 7 ~ 10 Za'a iya amfani da halin yanzu don aikin EDM na farko don rage lokacin aiki; 5 ~ 7 Ana iya amfani da halin yanzu don kammala machining. Manufar yin amfani da ƙananan halin yanzu shine don samun wuri mai kyau;

② Tabbatar da lallausan fuskar ƙarshen ƙuraje da kuma a tsaye na lantarki na jan ƙarfe. Rashin kwanciyar hankali na ƙarshen mold fuska ko rashin isasshen tsaye na lantarki na jan ƙarfe yana sa ya zama da wahala a tabbatar da cewa tsayin bel ɗin aiki bayan sarrafa EDM ya yi daidai da tsayin bel ɗin da aka tsara. Yana da sauƙi ga tsarin EDM ya kasa ko ma shiga bel ɗin aikin hakori. Sabili da haka, kafin sarrafa, dole ne a yi amfani da injin niƙa don daidaita ƙarshen duka biyun don saduwa da daidaitattun buƙatun, kuma dole ne a yi amfani da alamar bugun kira don gyara madaidaiciyar lantarki ta jan ƙarfe;

③ Tabbatar cewa tazarar da ke tsakanin wuƙaƙen da babu kowa a ciki ya yi daidai. A lokacin aikin injiniya na farko, bincika ko kayan aikin da ba komai an biya su kowane 0.2 mm kowane 3 zuwa 4 mm na sarrafawa. Idan kashewa ya yi girma, zai yi wahala a gyara shi tare da gyare-gyare na gaba;

④ Cire ragowar da aka samar a lokacin aikin EDM a cikin lokaci. Lalacewar fitar da walƙiya za ta haifar da raguwa mai yawa, wanda dole ne a tsabtace shi a cikin lokaci, in ba haka ba tsawon bel ɗin aiki zai bambanta saboda tsayi daban-daban na ragowar;

⑤ Dole ne a lalatar da mold kafin EDM.

5. Kwatanta sakamakon extrusion

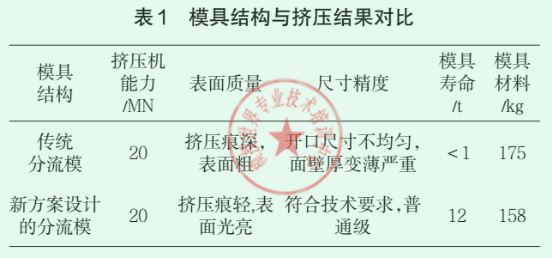

An gwada bayanin martabar da aka nuna a Hoto 1 ta amfani da tsaga na gargajiya da kuma sabon tsarin ƙira da aka gabatar a cikin wannan labarin. Ana nuna kwatancen sakamakon a cikin Tebu 1.

Ana iya gani daga sakamakon kwatancen cewa tsarin ƙirar yana da tasiri mai girma akan rayuwar ƙira. Samfurin da aka ƙera ta amfani da sabon tsarin yana da fa'ida a bayyane kuma yana inganta rayuwar ƙura.

6. Kammalawa

Fayil ɗin sunflower radiyo extrusion mold nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'i ne wanda ke da wuyar ƙira da ƙira, kuma ƙirarsa da masana'anta suna da rikitarwa. Saboda haka, don tabbatar da nasarar extrusion da kuma rayuwar sabis na mold, dole ne a cimma wadannan maki:

(1) Tsarin tsari na mold dole ne a zaba da kyau. Tsarin tsari dole ne ya kasance mai dacewa don rage ƙarfin extrusion don rage damuwa a kan ƙwanƙwasa ƙura da aka kafa ta hakora masu zafi na zafi, don haka inganta ƙarfin ƙirar. Makullin shine don ƙayyade ƙima da tsari na ramukan shunt da yanki na ramukan shunt da sauran sigogi: na farko, nisa na gadar shunt da aka kafa tsakanin ramukan shunt kada ya wuce 16mm; Na biyu, ya kamata a ƙayyade yankin ramin rabe don rabon rabo ya kai fiye da 30% na extrusion rabo kamar yadda zai yiwu yayin da tabbatar da ƙarfin mold.

(2) Haƙiƙa zaɓi bel ɗin aiki da ɗaukar matakan da suka dace yayin injin lantarki, gami da fasahar sarrafa na'urorin lantarki da ma'aunin daidaitattun lantarki na injin lantarki. Mahimmin mahimmin abu na farko shi ne cewa wutar lantarkin tagulla yakamata ta kasance ƙasa ƙasa kafin yanke waya, sannan a yi amfani da hanyar shigar lokacin yankan waya don tabbatar da ita. Wutar lantarki ba su da sako-sako ko nakasu.

(3) A lokacin aikin injin lantarki, lantarki dole ne a daidaita daidai gwargwado don guje wa karkacewar hakori. Hakika, bisa ga m zane da kuma masana'antu, yin amfani da high quality-zafi-aiki mold karfe da kuma injin zafi magani tsari na uku ko fiye da fushi na iya kara yawan m mold da kuma cimma sakamako mafi kyau. Daga ƙira, masana'anta zuwa samar da extrusion, kawai idan kowane hanyar haɗin kai daidai ne za mu iya tabbatar da cewa an fitar da ƙirar bayanin martabar sunflower.

Lokacin aikawa: Agusta-01-2024