Sauƙaƙan nauyin motoci shine manufa ɗaya ta masana'antar kera motoci ta duniya. Ƙara yawan amfani da kayan aluminium a cikin kayan haɗin mota shine jagorancin ci gaba don sababbin motocin zamani. 6082 aluminum gami ne mai zafi-treatable, ƙarfafa aluminum gami da matsakaici ƙarfi, m formability, weldability, gajiya juriya, da kuma lalata juriya. Ana iya fitar da wannan gami a cikin bututu, sanduna, da bayanan martaba, kuma ana amfani da shi sosai a cikin abubuwan keɓancewa na kera motoci, sassan tsarin walda, sufuri, da masana'antar gini.

A halin yanzu, akwai iyakataccen bincike akan 6082 aluminum gami don amfani da sabbin motocin makamashi a China. Sabili da haka, wannan binciken na gwaji yana bincikar tasirin 6082 aluminium alloy element na kewayon abun ciki, sigogin tsarin extrusion, hanyoyin kashewa, da dai sauransu, akan aikin bayanin alloy da microstructure. Wannan binciken yana nufin haɓaka abubuwan haɗin gwal da sigogin tsari don samar da kayan gami na aluminum na 6082 wanda ya dace da sabbin motocin makamashi.

1. Kayayyakin Gwaji da Hanyoyi

Gwajin tsari kwarara: Alloy abun da ke ciki rabo – Ingot narkewa – Ingot homogenization – Ingot sawing cikin billets – Extrusion na profiles – In-line quenching na bayanan martaba – Artificial tsufa – Shiri na gwaji samfurori.

1.1 Shiri Ingot

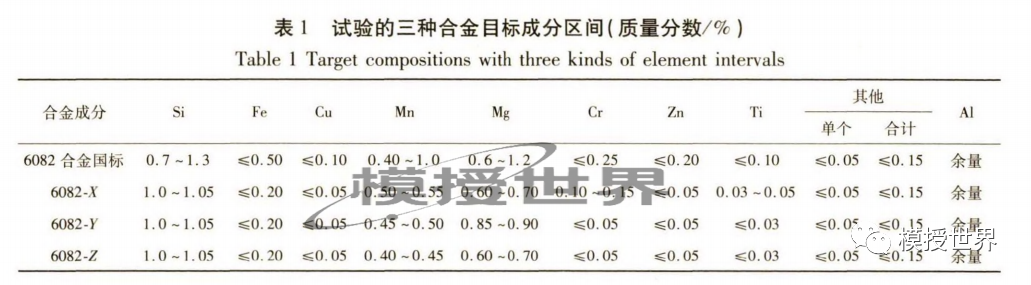

A cikin kewayon ƙasashen duniya na 6082 aluminium gami, an zaɓi abubuwan ƙira guda uku tare da kunkuntar kewayon sarrafawa, mai lakabin 6082-/6082″, 6082-Z, tare da abun ciki na Si iri ɗaya. Abubuwan da ke cikin Mg, y > z; Mn abun ciki, x > y > z; Cr, abun ciki na Ti, x > y = z. Ana nuna ƙimar ƙimar ƙayyadaddun ƙayyadaddun kayan haɗin gwal a cikin Tebura 1. An yi simintin simintin gyare-gyare ta hanyar amfani da hanyar simintin sanyaya ruwa mai ci gaba da ci gaba, sannan maganin homogenization. Dukkanin ingots guda uku an daidaita su ta amfani da tsarin kafa na masana'anta a 560 ° C na awanni 2 tare da sanyaya hazo na ruwa.

1.2 Fitar Bayanan Bayanai

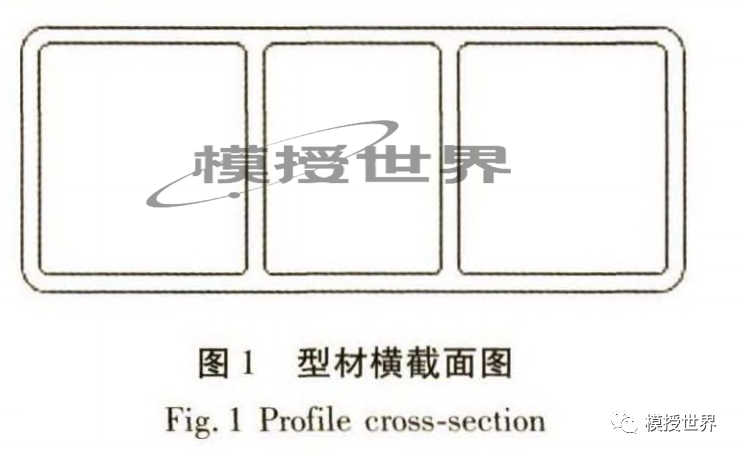

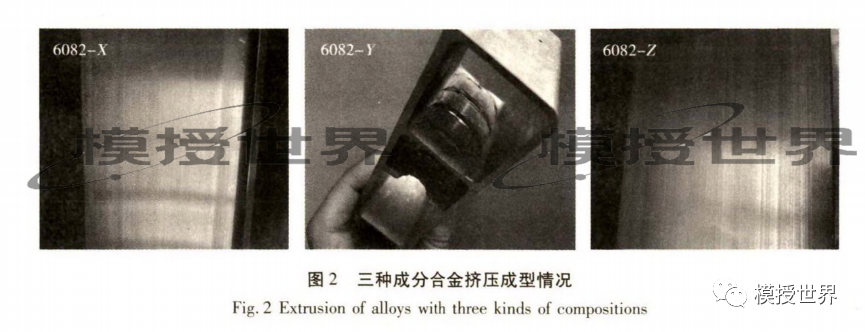

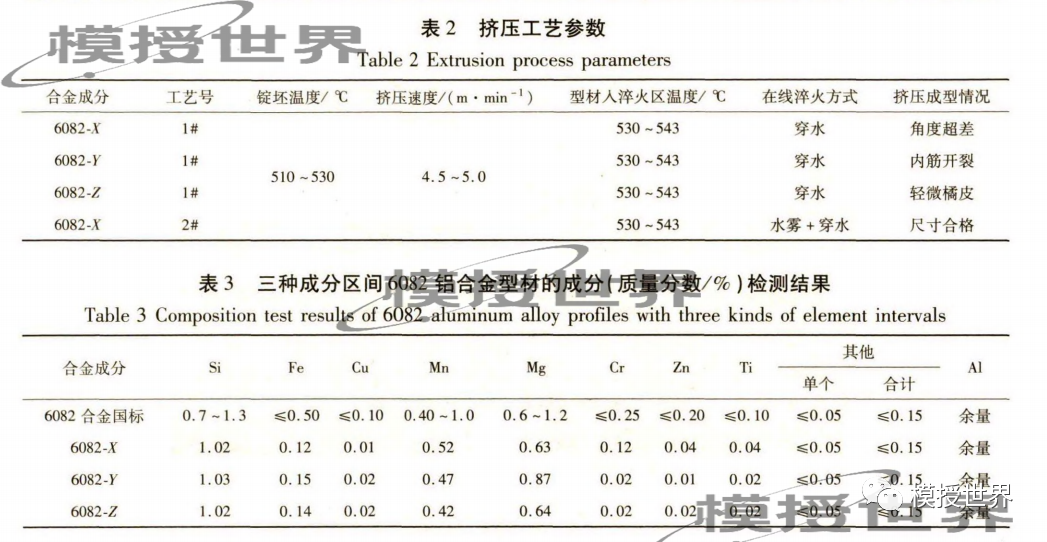

An daidaita sigogin tsarin extrusion daidai don dumama zafin billet da ƙimar sanyaya. An nuna sashin giciye na bayanan bayanan da aka fitar a cikin Hoto 1. An nuna sigogin tsarin extrusion a cikin Tebur 2. Matsayin kafa na bayanan martaba an nuna shi a cikin Hoto 2.

2.Sakamakon Gwaji da Nazari

Ƙayyadaddun ƙayyadaddun sinadarai na bayanan bayanan alloy na 6082 na aluminium a cikin jeri guda uku an ƙaddara ta amfani da sikirin karantawa kai tsaye na Swiss ARL, kamar yadda aka nuna a cikin Table 3.

2.1 Gwajin Aiki

Don kwatantawa, an yi nazarin aikin bayanan martaba na kewayon abun ciki guda uku tare da hanyoyi daban-daban na quenching, sigogi iri ɗaya na extrusion, da matakan tsufa.

2.1.1 Aikin Injini

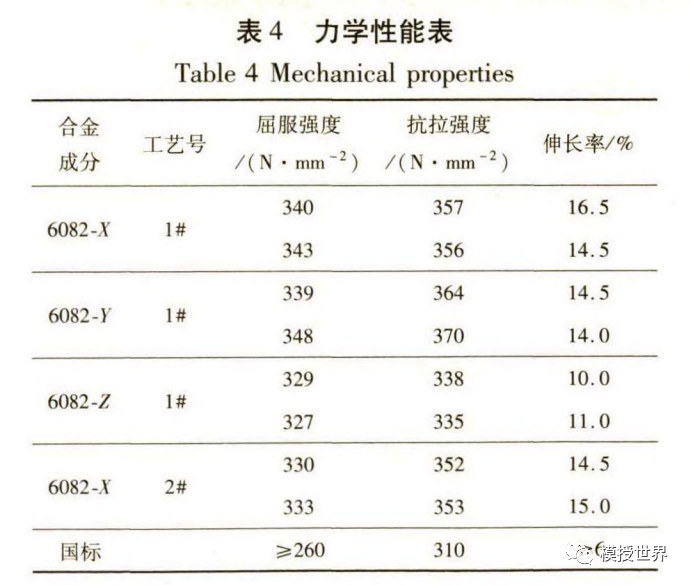

Bayan tsufa na wucin gadi a 175 ° C na tsawon sa'o'i 8, an ɗauki daidaitattun samfurori daga hanyar extrusion na bayanan martaba don gwajin tensile ta amfani da na'urar gwajin lantarki ta Shimadzu AG-X100. Ayyukan injina bayan tsufa na wucin gadi don abubuwan ƙira daban-daban da hanyoyin kashewa ana nuna su a cikin Tebura 4.

Daga Table 4, ana iya ganin cewa aikin injiniya na duk bayanan martaba ya wuce daidaitattun ƙimar ƙasa. Bayanan bayanan da aka samar daga 6082-Z alloy billlets suna da ƙananan haɓaka bayan karaya. Bayanan martaba da aka samar daga 6082-7 alloy billlets sun sami mafi girman aikin injina. 6082-X alloy profiles, tare da daban-daban m hanyoyin mafita, nuna mafi girma yi tare da m sanyaya hanyoyin quenching.

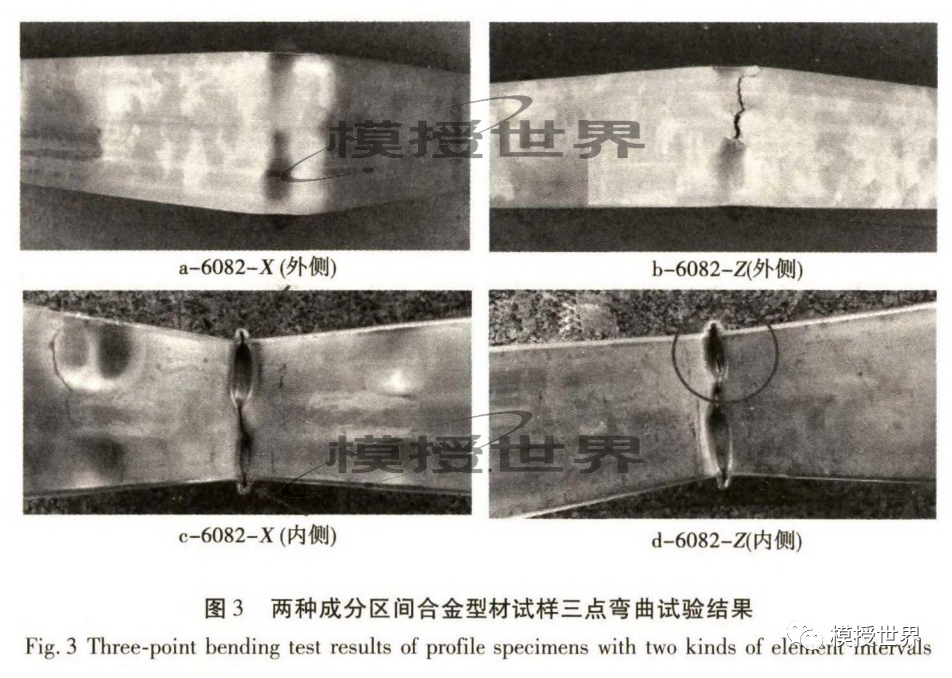

2.1.2 Lankwasawa Gwajin Aiki

Yin amfani da na'urar gwajin lantarki ta duniya, an gudanar da gwaje-gwajen lankwasa maki uku akan samfurori, kuma an nuna sakamakon lankwasawa a cikin Hoto na 3. Hoto na 3 ya nuna cewa samfurori da aka samar daga 6082-Z alloy billlets suna da bawon lemu mai tsanani a saman da kuma fashewa a bayan samfuran lanƙwasa. Kayayyakin da aka samar daga 6082-X alloy billlets sun sami kyakkyawan aiki na lankwasa, filaye masu santsi ba tare da kwasfa na lemu ba, kuma ƙananan fasa a wurare da aka iyakance ta yanayin geometric a bayan samfuran lanƙwasa.

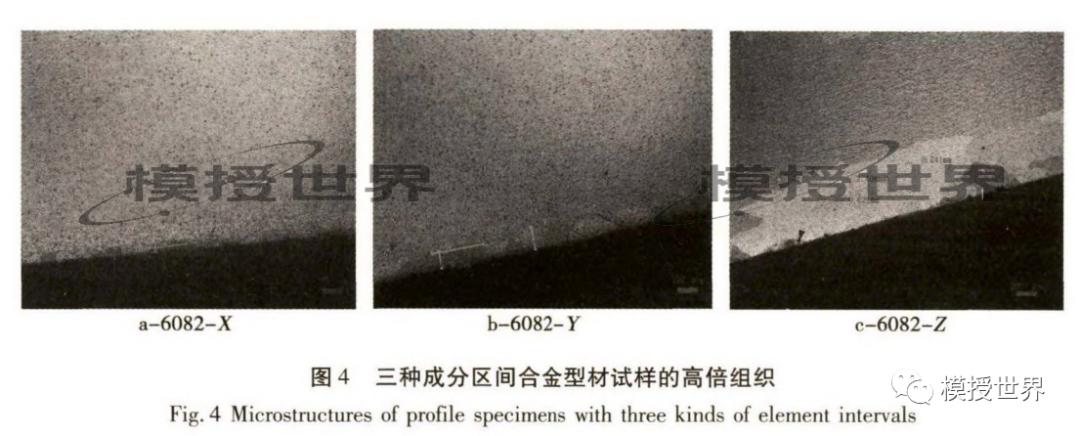

2.1.3 Babban Dubawa Mai Girma

An lura da samfurori a ƙarƙashin na'urar gani na gani na Carl Zeiss AX10 don nazarin microstructure. Sakamakon bincike na microstructure na nau'in nau'i na nau'i na nau'i na nau'in nau'i guda uku an nuna su a cikin Hoto 4. Hoto 4 yana nuna cewa girman hatsi na samfurori da aka samar daga 6082-X sanda da 6082-K alloy billets sun kasance irin wannan, tare da ƙananan ƙwayar hatsi a cikin 6082-X alloy idan aka kwatanta da 6082-y alloy. Kayayyakin da aka samar daga 6082-Z alloy billlets suna da girman hatsi masu girma da yadudduka masu kauri, wanda cikin sauƙi ya haifar da bawon lemu da raunin haɗin ƙarfe na ciki.

2.2 Binciken Sakamako

Dangane da sakamakon gwajin da ke sama, ana iya ƙarasa da cewa ƙira na kewayon abun ciki na gami yana tasiri sosai ga microstructure, aiki, da haɓakar bayanan bayanan da aka fitar. Ƙara yawan abun ciki na Mg yana rage ƙyallen alloy kuma yana haifar da samuwar fashewa yayin extrusion. Mafi girma Mn, Cr, da abun ciki na Ti suna da tasiri mai kyau a kan tace ƙananan ƙananan abubuwa, wanda hakan yana tasiri tasiri mai kyau a saman, aikin lankwasawa, da kuma aikin gaba ɗaya.

3.Kammalawa

Mg element muhimmanci rinjayar inji yi na 6082 aluminum gami. Ƙara yawan abun ciki na Mg yana rage ƙyallen alloy kuma yana haifar da samuwar fashewa yayin extrusion.

Mn, Cr, da Ti suna da tasiri mai kyau akan gyaran gyare-gyare na microstructure, wanda ke haifar da ingantacciyar inganci da kuma lankwasawa na samfuran extruded.

Daban-daban quenching sanyaya intensities suna da m tasiri a kan yi na 6082 aluminum gami profiles. Don amfani da mota, ɗaukar tsarin kashe hazo na ruwa wanda ke biye da sanyayawar ruwa yana samar da ingantacciyar aikin injina kuma yana tabbatar da siffar bayanan martaba da daidaiton girma.

May Jiang ta gyara daga MAT Aluminum

Lokacin aikawa: Maris 26-2024