A lokacin aikin extrusion na aluminum gami da extruded kayan, musamman aluminum profiles, a "pitting" lahani sau da yawa faruwa a kan surface. Takamaiman bayyanuwar sun haɗa da ƙananan ciwace-ciwace tare da ɗimbin yawa, wutsiya, da zahirin ji na hannu, tare da jin daɗi. Bayan oxidation ko electrophoretic surface jiyya, sukan bayyana a matsayin baki granules manne da saman samfurin.

A cikin extrusion samar da manyan-section profiles, wannan lahani ne mafi kusantar faruwa saboda da tasiri na ingot tsarin, extrusion zafin jiki, extrusion gudun, mold hadaddun, da dai sauransu Mafi yawa daga cikin lafiya barbashi na pitted lahani za a iya cire a lokacin profile surface pretreatment tsari, musamman da Alkali etching tsari, yayin da karamin adadin manyan-sized, barbashi da tabbaci shafi samfurin a kan bayyanar da inganci, da tabbaci a kan bayyanar.

A cikin ƙofa na yau da kullun da samfuran bayanin martaba na taga, abokan ciniki gabaɗaya suna karɓar ƙananan lahani, amma don bayanan martaba na masana'antu waɗanda ke buƙatar fifiko daidai kan kaddarorin injina da aikin kayan ado ko ƙarin fifiko kan aikin kayan ado, gabaɗaya abokan ciniki ba sa karɓar wannan lahani, musamman lahani waɗanda ba su dace da launi daban-daban ba.

Don yin nazarin tsarin samar da ƙananan ƙwayoyin cuta, an yi nazarin ilimin halittar jiki da abun da ke ciki na wurare masu lahani a ƙarƙashin nau'i-nau'i daban-daban da tsarin extrusion, kuma an kwatanta bambance-bambance tsakanin lahani da matrix. An gabatar da mafita mai ma'ana don magance ƙaƙƙarfan barbashi yadda ya kamata, kuma an gudanar da gwajin gwaji.

Don warware matsalar rami na bayanan martaba, ya zama dole a fahimci tsarin samar da lahani. A lokacin aiwatar da extrusion, aluminum manne wa mutu aiki bel ne babban dalilin pitting lahani a saman extruded aluminum kayan. Wannan shi ne saboda tsarin extrusion na aluminum ana aiwatar da shi a wani babban zafin jiki na kimanin 450 ° C. Idan an ƙara tasirin zafi na naƙasa da zafi mai jujjuyawa, zafin ƙarfe zai yi girma lokacin da ya fita daga cikin rami mai mutu. Lokacin da samfurin ya fita daga cikin rami mai mutu, saboda yawan zafin jiki, akwai wani abu na aluminum yana manne tsakanin karfe da bel ɗin aiki.

Siffar wannan haɗin kai sau da yawa: tsarin maimaitawa na haɗin gwiwa - tsagewa - haɗin kai - sake tsagewa, kuma samfurin yana gudana gaba, yana haifar da ƙananan ƙananan ramuka a saman samfurin.

Wannan al'amari na haɗin kai yana da alaƙa da abubuwa kamar ingancin ingot, yanayin yanayin bel ɗin aiki, yanayin zafi, saurin extrusion, matakin nakasawa, da juriya na nakasar ƙarfe.

1 Gwaji kayan aiki da hanyoyin

Ta hanyar bincike na farko, mun koyi cewa abubuwa irin su tsabtataccen ƙarfe, matsayi na mold, tsarin extrusion, sinadaran, da yanayin samarwa na iya rinjayar barbashi mai roughened. A cikin gwajin, an yi amfani da sandunan alloy guda biyu, 6005A da 6060, don fitar da sashe ɗaya. An yi nazarin ilimin halittar ɗan adam da abun da ke ciki na roughened barbashi matsayi ta hanyar kai tsaye karanta spectrometer da SEM gano hanyoyin, kuma idan aka kwatanta da kewaye al'ada matrix.

Domin a fayyace fayyace nau’in halitta guda biyu na pitted da barbashi, an ayyana su kamar haka:

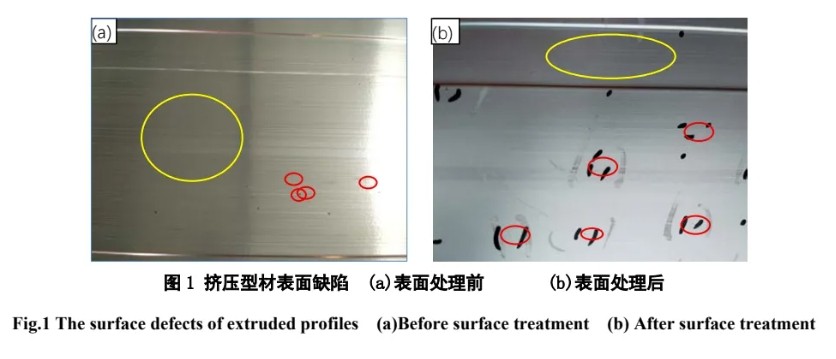

(1) Rashin lahani ko lahani na ja wani nau'in lahani ne wanda yake shi ne naƙasa mara kyau kamar tadpole ko ma'auni wanda ke bayyana a saman bayanin martaba. Lalacewar yana farawa daga ɗigon karce kuma yana ƙarewa tare da lahani yana faɗuwa, yana tarawa cikin wake na ƙarfe a ƙarshen layin karce. Girman lahani gabaɗaya 1-5mm, kuma yana juya duhu bayan jiyya na iskar shaka, wanda a ƙarshe yana shafar bayyanar bayanin martaba, kamar yadda aka nuna a da'irar ja a cikin hoto 1.

(2) Barbasar saman kuma ana kiranta da waken ƙarfe ko kuma ɓangarorin talla. Ana haɗe saman bayanin martabar alloy ɗin aluminium tare da barbashi mai launin toka-baƙi mai ƙarfi kuma yana da tsari mara kyau. Akwai nau'ikan bayanan allo na aluminum iri biyu: waɗanda za a iya gogewa da waɗanda ba za a iya goge su ba. Girman gabaɗaya bai wuce 0.5mm ba, kuma yana jin ƙaƙƙarfan taɓawa. Babu karce a sashin gaba. Bayan oxidation, bai bambanta da matrix ba, kamar yadda aka nuna a da'irar rawaya a cikin hoto 1.

2 Sakamakon gwaji da bincike

2.1 Lalacewar jan fuskar saman

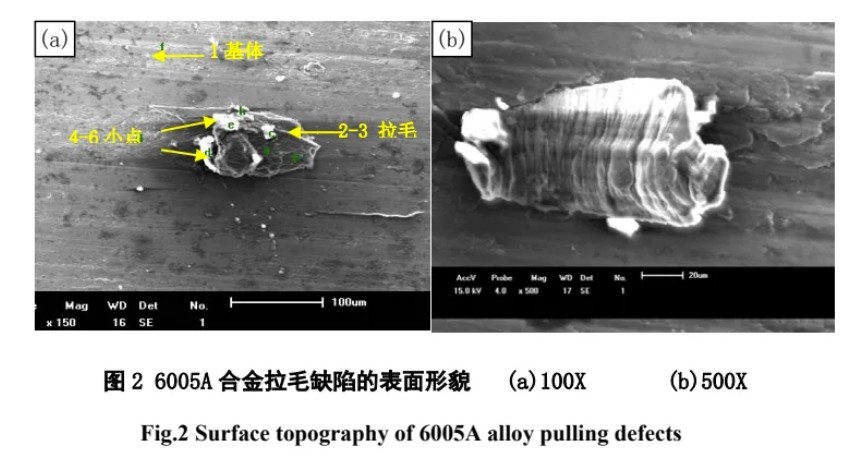

Hoto na 2 yana nuna ƙirar ƙirar ƙirar ƙira na lahani mai ja akan saman alloy na 6005A. Akwai karce-kamar mataki a ɓangaren gaba na ja, kuma suna ƙarewa da nodules ɗin da aka tattara. Bayan nodules sun bayyana, farfajiyar ta dawo al'ada. Wurin da ke da lahani ba shi da santsi ga taɓawa, yana da ƙaƙƙarfan jin ƙaya, kuma yana mannewa ko taruwa a saman bayanin martaba. Ta hanyar gwajin extrusion, an lura cewa ƙwanƙwasa ilimin halittar jiki na 6005A da 6060 extruded profiles yana kama da shi, kuma wutsiya na samfurin ya fi girman kai; Bambanci shine cewa girman girman 6005A gabaɗaya ya fi ƙanƙanta kuma zurfin karce ya raunana. Wannan na iya kasancewa yana da alaƙa da canje-canje a cikin abun da ke ciki na gami, yanayin sandar simintin gyare-gyare, da yanayin ƙira. An lura da shi a ƙarƙashin 100X, akwai alamun ɓarna a gaban ƙarshen yanki na ja, wanda aka haɓaka tare da jagorancin extrusion, kuma siffar ƙwayoyin nodule na ƙarshe ba daidai ba ne. A 500X, ƙarshen gaba na farfajiyar ja yana da matakan-kamar ɓarna tare da jagorar extrusion (girman wannan lahani shine kusan 120 μm), kuma akwai alamun tari a bayyane akan ƙwayoyin nodular a ƙarshen wutsiya.

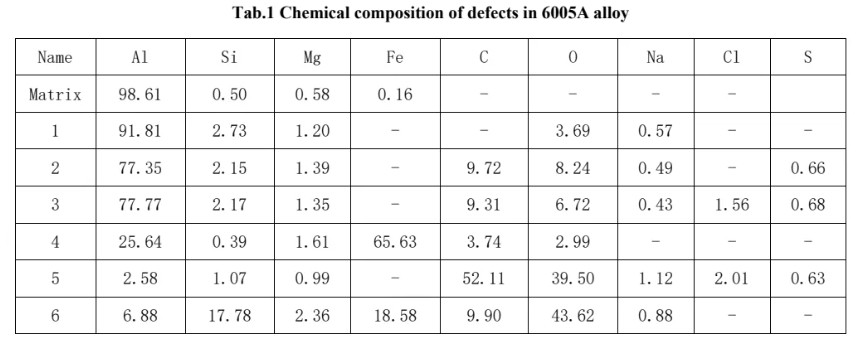

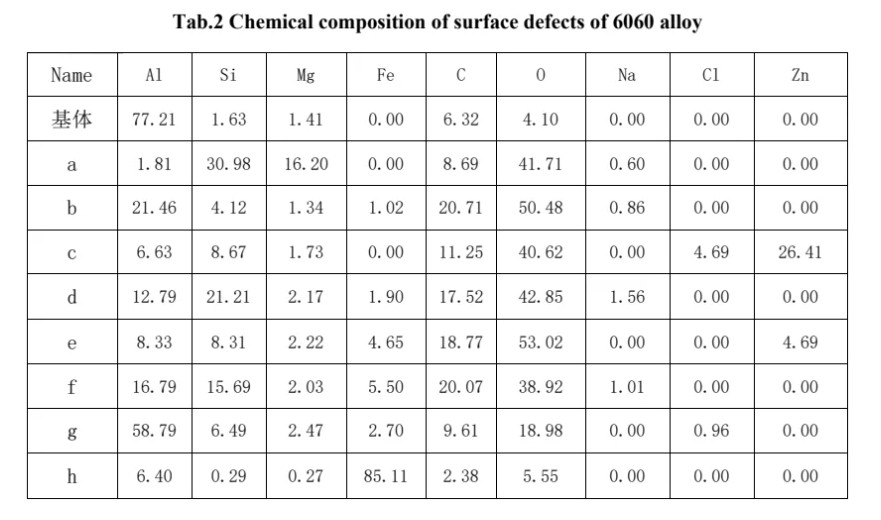

Don yin nazarin abubuwan da ke haifar da ja, an yi amfani da sikirin karantawa kai tsaye da EDX don gudanar da nazarin sassa akan wuraren lahani da matrix na abubuwan haɗin gwal guda uku. Table 1 yana nuna sakamakon gwajin bayanin martabar 6005A. Sakamakon EDX ya nuna cewa abun da ke ciki na matsayin stacking na ɓangarorin ja yana kama da na matrix. Bugu da kari, ana tara wasu ɓangarorin ƙazanta masu kyau a ciki da kuma kewaye da lahani na ja, kuma ɓangarorin najasa sun ƙunshi C, O (ko Cl), ko Fe, Si, da S.

Analysis na roughening lahani na 6005A lafiya oxidized extruded profiles nuna cewa ja barbashi ne manyan a size (1-5mm), da surface ne mafi yawa stacked, kuma akwai mataki-kamar scratches a kan gaba sashe; Abun da ke ciki yana kusa da Al matrix, kuma za a sami matakai daban-daban masu ɗauke da Fe, Si, C, da O da aka rarraba kewaye da shi. Ya nuna cewa tsarin da ake ja na nau'ikan alloli guda uku iri ɗaya ne.

A lokacin aiwatar da extrusion, juzu'in kwararar ƙarfe zai haifar da zafin jiki na bel ɗin aiki ya tashi, yana samar da "layin aluminum mai ɗaci" a ƙarshen ƙofar bel ɗin aiki. A lokaci guda, wuce haddi Si da sauran abubuwa kamar Mn da Cr a cikin aluminum gami suna da sauƙi don samar da mafita mai ƙarfi tare da Fe, wanda zai haɓaka samuwar "layin aluminum mai ɗaci" a ƙofar yankin aiki na mold.

Yayin da ƙarfen ke gudana gaba da gogewa da bel ɗin aiki, wani abu mai maimaitawa na ci gaba da haɗa haɗin kai-yaga-ƙulla yana faruwa a wani matsayi, yana haifar da ƙarfe ya ci gaba da girma a wannan matsayi. Lokacin da barbashi ya ƙaru zuwa ƙayyadaddun girman, samfurin da ke gudana zai janye shi kuma ya zama alamun karce akan saman ƙarfe. Zai kasance a saman saman ƙarfe kuma ya zama ɓangarorin ja a ƙarshen karce. Saboda haka, ana iya la'akari da cewa samuwar roughened barbashi ne yafi alaka da aluminum manne wa mold aiki bel. Matsalolin daban-daban da aka rarraba a kusa da shi na iya samo asali daga mai mai, oxides ko barbashi na kura, da kuma ƙazanta waɗanda ƙaƙƙarfan saman ingot ya kawo.

Koyaya, adadin ja a cikin sakamakon gwajin 6005A ya fi ƙanƙanta kuma digiri ya fi sauƙi. A daya hannun, shi ne saboda chamfering a fita daga mold aiki bel da kuma a hankali polishing na aiki bel don rage kauri daga cikin aluminum Layer; a gefe guda, yana da alaƙa da abubuwan da ke cikin Si.

Dangane da sakamakon abubuwan da aka haɗa na karatun kai tsaye, ana iya ganin cewa ban da Si a haɗe da Mg Mg2Si, sauran Si ya bayyana a cikin nau'in abu mai sauƙi.

2.2 Ƙananan barbashi a saman

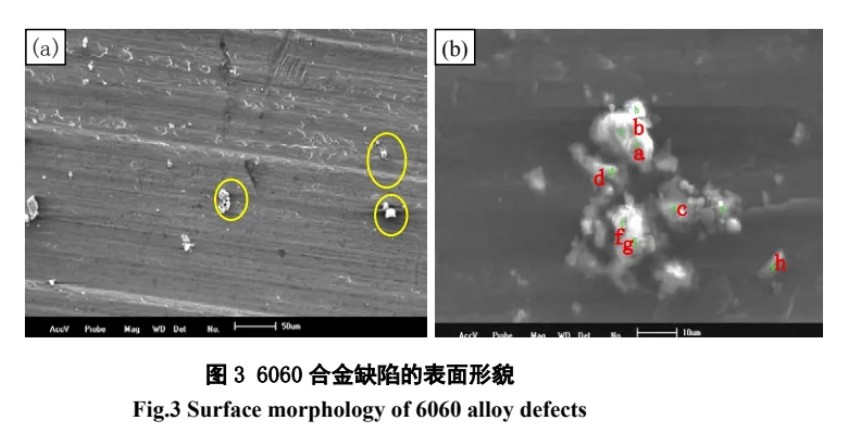

Ƙarƙashin ƙananan duban gani na gani, barbashi ƙananan ƙananan (≤0.5mm), ba su da santsi ga taɓawa, suna da jin dadi, kuma suna manne da saman bayanin martaba. An lura da shi a ƙarƙashin 100X, ƙananan ƙwayoyin da aka rarraba a saman suna rarraba ba tare da izini ba, kuma akwai ƙananan ƙananan ƙwayoyin da aka haɗe zuwa saman ba tare da la'akari da ko akwai raguwa ko a'a ba;

A 500X, ko da ko akwai bayyananne mataki-kamar scratches a kan surface tare da extrusion shugabanci, da yawa barbashi har yanzu a haɗe, da barbashi girma dabam dabam. Mafi girman girman barbashi shine kusan μm 15, kuma ƙananan ƙwayoyin suna kusan 5 μm.

Ta hanyar nazarin abun da ke ciki na 6060 alloy surface barbashi da kuma m matrix, barbashi an yafi hada da O, C, Si, da Fe abubuwa, da aluminum abun ciki ne sosai low. Kusan dukkan barbashi sun ƙunshi abubuwan O da C. A abun da ke ciki na kowane barbashi ne dan kadan daban-daban. Daga cikin su, ƙwayoyin suna kusa da 10 μm, wanda ya fi girma fiye da matrix Si, Mg, da O; A cikin sassan c, Si, O, da Cl sun fi girma a fili; Barbashi d da f sun ƙunshi babban Si, O, da Na; ɓangarorin e sun ƙunshi Si, Fe, da O; h barbashi su ne Fe-dauke da mahadi. Sakamakon ƙwayoyin 6060 sun yi kama da wannan, amma saboda abun ciki na Si da Fe a cikin 6060 kanta ba shi da ƙasa, abubuwan da ke cikin Si da Fe a cikin sassan saman ma sun yi ƙasa; abun ciki na C a cikin barbashi 6060 yana da ɗan ƙaramin ƙarfi.

Kwayoyin da ke saman ƙasa ba za su zama ƙananan ƙananan barbashi ba, amma kuma suna iya kasancewa a cikin nau'i na nau'i na ƙananan ƙwayoyin cuta masu yawa masu siffofi daban-daban, kuma yawan adadin abubuwa daban-daban a cikin barbashi daban-daban sun bambanta. An yi imani da cewa barbashi an yafi hada da iri biyu. Ɗaya shine hazo irin su AlFeSi da elemental Si, waɗanda suka samo asali daga babban yanayin narkewar ƙazanta kamar FeAl3 ko AlFeSi(Mn) a cikin ingot, ko matakan haɓaka yayin aiwatar da extrusion. Dayan kuma shi ne al'amarin waje mai ma'ana.

2.3 Tasirin rashin ƙarfi na ingot

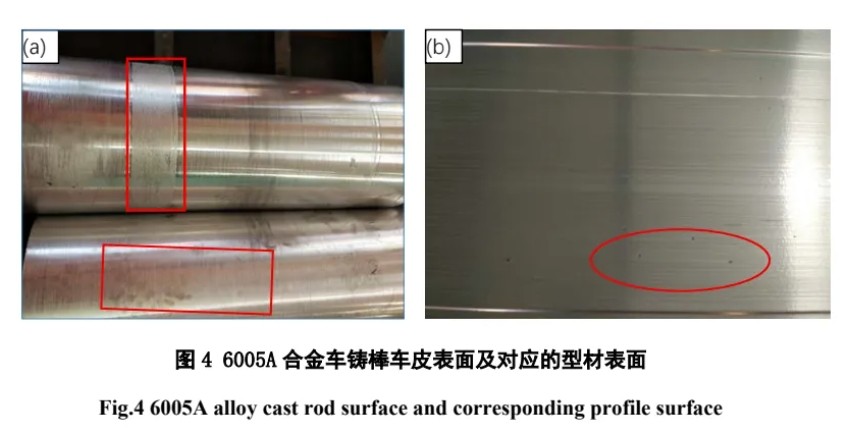

A lokacin gwajin, an gano cewa saman baya na 6005A simintin lathe na simintin gyare-gyare yana da ƙaƙƙarfa kuma yana cike da ƙura. Akwai sandunan simintin gyare-gyare guda biyu tare da alamar kayan aiki mai zurfi mafi zurfi a wurare na gida, wanda ya dace da karuwa mai yawa a cikin adadin ja bayan fitar da shi, kuma girman ja guda ɗaya ya fi girma, kamar yadda aka nuna a hoto na 7.

Simintin simintin 6005A ba shi da lathe, don haka ƙarancin ƙasa yana da ƙasa kuma an rage adadin ja. Bugu da kari, tunda babu ruwan yankan da ya wuce gona da iri da aka haɗe zuwa alamar lathe na sandar simintin gyare-gyare, abun cikin C yana raguwa. An tabbatar da cewa alamomin juyawa a saman sandar simintin gyare-gyaren za su ƙara ja da samuwar barbashi zuwa wani matsayi.

3 Tattaunawa

(1) Abubuwan da ke tattare da lahani na ja suna daidai da na matrix. Shi ne na waje barbashi, tsohon fata a saman da ingot da sauran datti tara a cikin extrusion ganga bango ko matattu yankin na mold a lokacin extrusion tsari, wanda aka kawo zuwa karfe surface ko aluminum Layer na mold aiki bel. Yayin da samfurin ke gudana gaba, ana haifar da ɓarna a saman, kuma lokacin da samfurin ya taru zuwa wani ƙayyadaddun girman, samfurin zai fitar da shi don yin ja. Bayan oxidation, cirewar ya lalace, kuma saboda girmansa, akwai lahani kamar rami a wurin.

(2) Barbasar saman wani lokaci suna bayyana a matsayin ƙananan barbashi guda ɗaya, wani lokaci kuma suna kasancewa a cikin tari. Haɗin su a fili ya bambanta da na matrix, kuma galibi ya ƙunshi abubuwan O, C, Fe, da Si. Wasu daga cikin ɓangarorin sun mamaye abubuwan O da C, wasu kuma sun mamaye O, C, Fe, da Si. Don haka, ana kiyasin cewa barbashi na saman sun fito ne daga tushe guda biyu: daya hazo ne kamar su AlFeSi da elemental Si, da kazanta kamar O da C suna manne da saman; Dayan kuma shi ne al'amarin waje mai ma'ana. Barbashi sun lalace bayan oxidation. Saboda ƙananan girman su, ba su da tasiri ko kadan a saman.

(3) Barbashi masu albarkar C da O sun fi fitowa ne daga mai mai, ƙura, ƙasa, iska da sauransu. Babban abubuwan da ake hadawa da man shafawa sune C, O, H, S, da sauransu, kuma babban bangaren kura da kasa shine SiO2. Abun cikin O na barbashi na saman gabaɗaya yana da girma. Saboda barbashi suna cikin yanayin zafi mai zafi nan da nan bayan barin bel ɗin aiki, kuma saboda ƙayyadaddun yanki na musamman na barbashi, suna sauƙaƙe adsorb O atom a cikin iska kuma suna haifar da iskar shaka bayan haɗuwa da iska, wanda ke haifar da mafi girman O abun ciki fiye da matrix.

(4) Fe, Si, da dai sauransu sun fito ne daga oxides, tsohuwar sikelin da ƙazanta a cikin ingot (high melting point ko na biyu lokaci wanda ba a cika kawar da shi ta hanyar homogenization). The Fe element ya samo asali ne daga Fe a cikin ingots na aluminum, yana samar da matakan ƙazanta mai zurfi kamar FeAl3 ko AlFeSi (Mn), wanda ba za a iya narkar da shi a cikin m bayani a lokacin homogenization tsari, ko ba a cika tuba; Si ya wanzu a cikin matrix aluminum a cikin nau'i na Mg2Si ko ingantaccen bayani mai ƙarfi na Si yayin aikin simintin. Yayin aikin fitar da simintin simintin gyare-gyare mai zafi na simintin gyare-gyare, yawan Si zai iya yin hazo. Solubility na Si a cikin aluminum shine 0.48% a 450 ° C da 0.8% (wt%) a 500 ° C. Yawan abubuwan da ke cikin Si a cikin 6005 shine kusan 0.41%, kuma hazo Si yana iya zama tarawa da hazo da hazo ya haifar da hazo.

(5) Aluminum mai manne wa bel ɗin aiki shine babban dalilin ja. Mutuwar extrusion shine yanayin zafi mai zafi da matsa lamba. Karfe kwarara gogayya zai ƙara yawan zafin jiki na aiki bel na mold, forming wani "m aluminum Layer" a yankan gefen ƙofar bel aiki.

A lokaci guda, wuce haddi Si da sauran abubuwa kamar Mn da Cr a cikin aluminum gami suna da sauƙi don samar da mafita mai ƙarfi tare da Fe, wanda zai haɓaka samuwar "layin aluminum mai ɗaci" a ƙofar yankin aiki na mold. Ƙarfe ɗin da ke gudana ta cikin "layin aluminum mai ɗaci" na cikin gogayya ne (zamiya mai ƙarfi a cikin ƙarfe). Ƙarfe yana lalacewa kuma yana taurare saboda juzu'i na ciki, wanda ke haɓaka ƙarfen da ke cikin ƙasa da gyaggyarawa don manne tare. A lokaci guda, bel ɗin da ke aiki yana lalacewa zuwa siffar ƙaho saboda matsa lamba, kuma aluminum mai ɗaci da aka kafa ta ɓangaren yanki na bel ɗin aiki yana tuntuɓar bayanin martaba yana kama da yankan gefen kayan aiki na juyawa.

Samuwar aluminium mai ɗanko shine tsari mai ƙarfi na girma da zubarwa. Ana fitar da barbashi akai-akai ta hanyar bayanin martaba. Mace da saman bayanin martaba, yana haifar da lahani. Idan yana gudana kai tsaye daga bel ɗin aiki kuma nan da nan an shayar da shi a saman bayanin martaba, ƙananan barbashi da thermally manne a saman ana kiran su "barbashi adsorption". Idan wasu barbashi za su karye ta hanyar daɗaɗɗen aluminum gami, wasu barbashi za su tsaya a saman bel ɗin aiki lokacin wucewa ta bel ɗin aiki, haifar da ɓarna a saman bayanin martaba. Ƙarshen wutsiya shine matrix na aluminum. Lokacin da aluminum mai yawa makale a tsakiyar bel ɗin aiki (haɗin yana da ƙarfi), zai ƙara ɓarna saman.

(6) Gudun extrusion yana da tasiri mai girma akan ja. Tasirin saurin extrusion. Dangane da abin da aka lura da allo na 6005, saurin extrusion yana ƙaruwa a cikin kewayon gwaji, zafin fitarwa yana ƙaruwa, kuma adadin abubuwan jan ƙarfe yana ƙaruwa kuma yana ƙaruwa yayin da layin injin ya karu. Ya kamata a kiyaye saurin extrusion a matsayin karko kamar yadda zai yiwu don guje wa canje-canjen saurin sauri. Wuce kima gudun extrusion da high kanti zafin jiki zai haifar da ƙara gogayya da tsanani barbashi ja. Ƙimar ƙayyadaddun ƙayyadaddun tasirin tasirin extrusion a kan abin da ke jawowa yana buƙatar biyo baya da tabbaci.

(7) Ingancin saman sandar simintin gyare-gyare kuma muhimmin abu ne da ke shafar ɓangarorin ja. Fuskar sandar simintin gyare-gyaren yana da daɗaɗawa, tare da ƙwanƙwasa ciyayi, tabon mai, ƙura, lalata, da dai sauransu, waɗanda duk suna haɓaka halayen ja.

4 Kammalawa

(1) Abubuwan da ke tattare da lahani na ja sun dace da na matrix; abun da ke ciki na matsayin barbashi a fili ya bambanta da na matrix, galibi yana ƙunshe da abubuwan O, C, Fe, da Si.

(2) Jawo barbashi lahani aka yafi lalacewa ta hanyar aluminum manne wa mold aiki bel. Duk wani abubuwan da ke haɓaka aluminum manne wa bel ɗin aiki zai haifar da lahani. A kan yanayin tabbatar da ingancin simintin simintin gyare-gyare, tsararrun abubuwan jan hankali ba su da tasiri kai tsaye a kan haɗin gwal.

(3) Daidaitaccen maganin kashe gobara yana da amfani don rage jan ƙasa.

Lokacin aikawa: Satumba-10-2024