Babban bangon kauri 6061T6 aluminum gami yana buƙatar kashe bayan zafi mai zafi. Saboda ƙayyadaddun ƙayyadaddun ƙaddamarwa, wani ɓangare na bayanin martaba zai shiga yankin mai sanyaya ruwa tare da jinkiri. Lokacin da aka ci gaba da fitar da gajeriyar ingot na gaba, wannan ɓangaren bayanan za a yi jinkirin quenching. Yadda za a magance yankin jinkirin quenching al'amari ne da kowane kamfani ke buƙatar yin la'akari da shi. Lokacin da sharar ƙarewar wutsiya ta ƙare ta gajere, samfuran wasan kwaikwayon da aka ɗauka wani lokaci sun cancanta kuma wani lokacin rashin cancanta. Lokacin sake fasalin daga gefe, aikin ya sake cancanta. Wannan labarin yana ba da bayanin daidai ta hanyar gwaji.

1. Gwajin kayan aiki da hanyoyin

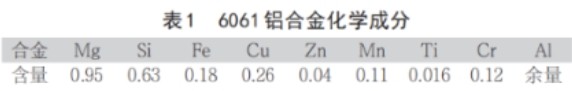

Abubuwan da aka yi amfani da su a cikin wannan gwaji shine 6061 aluminum gami. Abubuwan da ke tattare da sinadarai da aka auna ta hanyar bincike na kallo sune kamar haka: Ya dace da GB/T 3190-1996 na kasa da kasa 6061 aluminium abun da ke ciki.

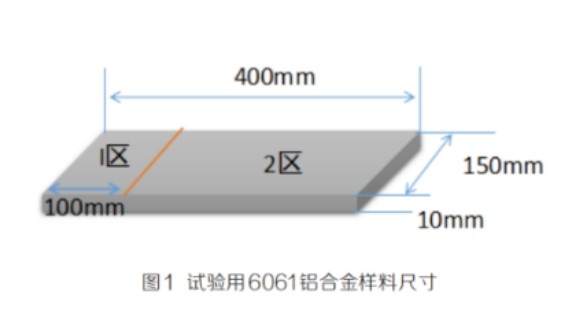

A cikin wannan gwaji, an ɗauki wani ɓangare na bayanin martabar da aka fitar don ingantaccen magani. An raba bayanin martaba mai tsayi 400mm zuwa wurare biyu. Wuri na 1 kai tsaye an sanyaya ruwa kuma an kashe shi. An sanyaya wuri na 2 a cikin iska don 90 seconds sannan kuma a sanyaya ruwa. Ana nuna hoton gwajin a hoto na 1.

6061 aluminium alloy profile da aka yi amfani da shi a cikin wannan gwaji an fitar da shi ta hanyar 4000UST extruder. The mold zafin jiki ne 500 ° C, da simintin sanda zafin jiki ne 510 ° C, da extrusion kanti zafin jiki ne 525 ° C, da extrusion gudun ne 2.1mm / s, high-m ruwa sanyaya da ake amfani a lokacin extrusion tsari, da kuma 400mm tsawon gwajin yanki da aka dauka daga tsakiyar extruded gama profile. Nisa samfurin shine 150mm kuma tsayin shine 10.00mm.

Samfuran da aka ɗauka an raba su sannan kuma an sake yin maganin maganin. Maganin zafin jiki shine 530 ° C kuma lokacin maganin shine 4 hours. Bayan fitar da su, an sanya samfurori a cikin babban tanki na ruwa tare da zurfin ruwa na 100mm. Babban tankin ruwa mai girma zai iya tabbatar da cewa yawan zafin jiki na ruwa a cikin tankin ruwa ya canza kadan bayan samfurin a cikin yanki na 1 yana sanyaya ruwa, yana hana karuwar yawan zafin ruwa daga tasirin ruwan sanyi. A lokacin aikin sanyaya ruwa, tabbatar da cewa zafin ruwan yana cikin kewayon 20-25 ° C. Samfurin da aka kashe sun kasance a 165 ° C * 8h.

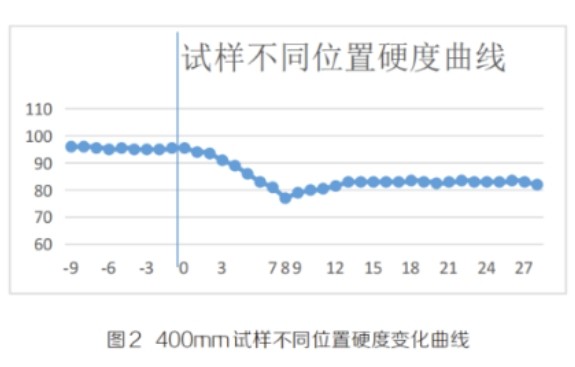

Ɗauki wani ɓangare na samfurin 400mm tsawon 30mm faɗin kauri 10mm, kuma yi gwajin taurin Brinell. Yi ma'auni 5 kowane 10mm. Ɗauki matsakaicin ƙimar 5 Brinell hardnesses a matsayin sakamakon taurin Brinell a wannan lokacin, kuma ku lura da yanayin canjin taurin.

An gwada kayan aikin injiniya na bayanin martaba, kuma sashin layi na 60mm an sarrafa shi a wurare daban-daban na samfurin 400mm don lura da kaddarorin ƙwanƙwasa da wuri mai fashe.

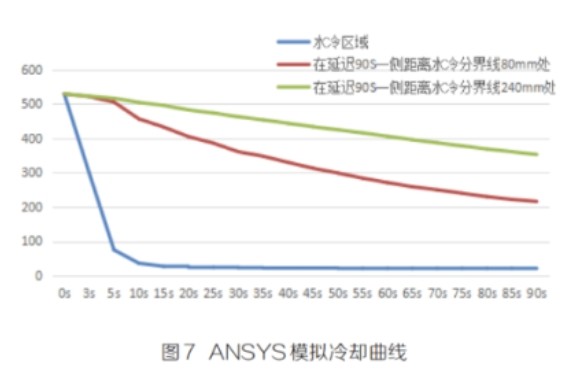

Filin zafin jiki na ruwan sanyi mai sanyi na samfurin samfurin da kuma quenching bayan jinkiri na 90s an kwatanta shi ta hanyar software na ANSYS, kuma an yi nazarin yanayin sanyi na bayanan martaba a wurare daban-daban.

2. Sakamakon gwaji da bincike

2.1 Sakamakon gwajin taurin

Hoto na 2 yana nuna alamar canjin taurin tsayin samfurin 400mm wanda aka auna ta mai gwajin taurin Brinell (tsawon naúrar abscissa yana wakiltar 10mm, kuma ma'auni na 0 shine layin rarraba tsakanin al'ada quenching da jinkirta quenching). Ana iya gano cewa taurin a ƙarshen ruwan sanyi yana da ƙarfi a kusan 95HB. Bayan layin raba tsakanin quenching mai sanyaya ruwa da jinkirin 90s mai sanyaya ruwa quenching, taurin ya fara raguwa, amma raguwar raguwa yana jinkirin a farkon mataki. Bayan 40mm (89HB), taurin yana faɗuwa sosai, kuma ya faɗi zuwa mafi ƙasƙanci (77HB) a 80mm. Bayan 80mm, taurin bai ci gaba da raguwa ba, amma ya karu zuwa wani matsayi. Ƙaruwar ya kasance kaɗan. Bayan 130mm, taurin ya kasance bai canza ba a kusa da 83HB. Ana iya yin hasashe cewa saboda tasirin zafi mai zafi, adadin sanyaya na ɓangaren da aka jinkirta ya canza.

2.2 Sakamakon gwajin aiki da bincike

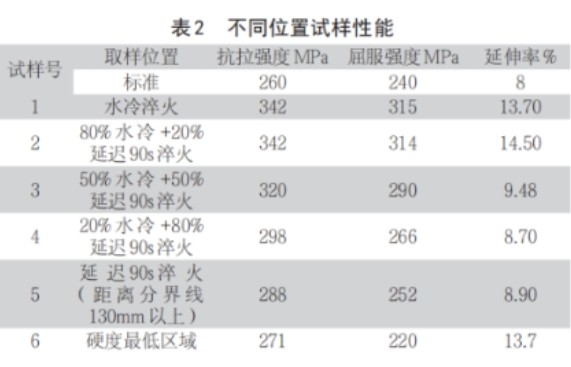

Shafin 2 yana nuna sakamakon gwaje-gwajen da aka yi a kan samfurori da aka ɗauka daga wurare daban-daban na sashin layi daya. Ana iya gano cewa ƙarfin ƙarfi da ƙarfin samar da ƙarfi na No. 1 da No. 2 ba su da kusan canji. Yayin da adadin jinkirin ƙarewar ƙarewa ya ƙaru, ƙarfin juzu'i da ƙarfin abin da ake samu na gami yana nuna babban yanayin ƙasa. Koyaya, ƙarfin juzu'i a kowane wurin samfur yana sama da daidaitaccen ƙarfin. Sai kawai a cikin yanki tare da mafi ƙasƙanci mafi ƙasƙanci, ƙarfin yawan amfanin ƙasa ya fi ƙasa da samfurin samfurin, aikin samfurin bai cancanta ba.

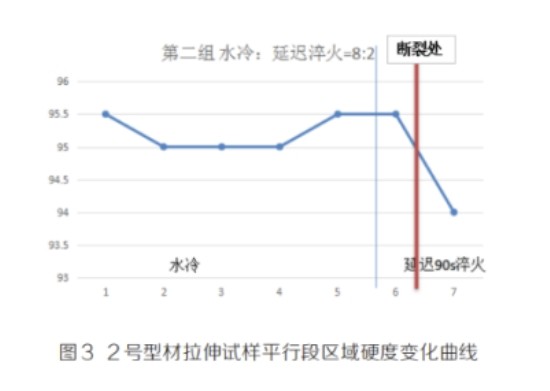

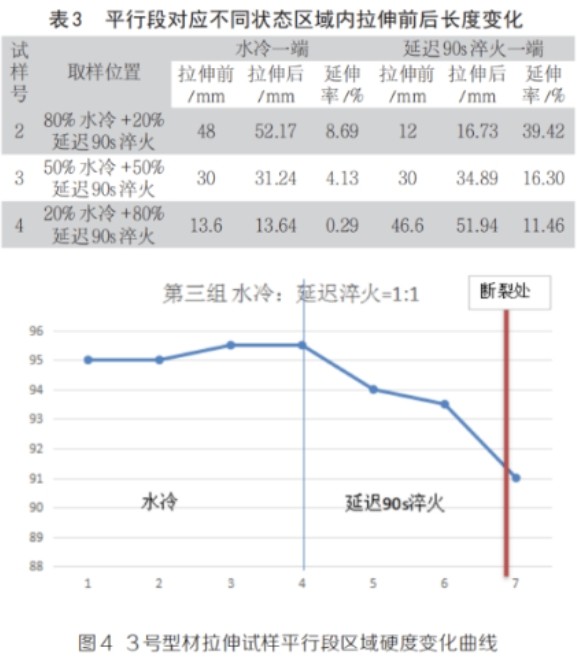

Hoto na 4 yana nuna sakamakon kaddarorin ƙwanƙwasa na samfurin No. 3. Ana iya samuwa daga Hoto 4 cewa mafi nisa daga layin rarrabawa, ƙananan taurin ƙarshen ƙarewar da aka jinkirta. Rage taurin yana nuna cewa aikin samfurin ya ragu, amma taurin yana raguwa a hankali, yana raguwa daga 95HB zuwa kusan 91HB a ƙarshen sashin layi daya. Kamar yadda ake iya gani daga sakamakon wasan kwaikwayon a cikin Teburin 1, ƙarfin ƙarfi ya ragu daga 342MPa zuwa 320MPa don sanyaya ruwa. A lokaci guda kuma, an gano cewa ɓarkewar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar cuta ita ma a ƙarshen sashin layi ɗaya tare da mafi ƙasƙanci. Wannan shi ne saboda yana da nisa da sanyaya ruwa, aikin gami yana raguwa, kuma ƙarshen ya kai iyakar ƙarfin ƙarfi da farko don samar da wuyansa. A ƙarshe, karya daga mafi ƙanƙanta wurin aiki, kuma matsayin hutu ya yi daidai da sakamakon gwajin aiki.

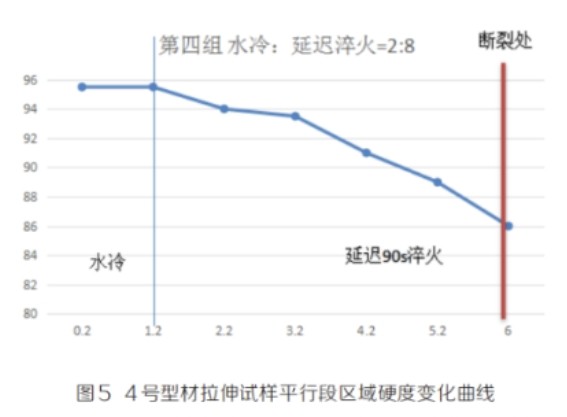

Hoto na 5 yana nuna maƙalar taurin sashin layi ɗaya na samfurin A'a. 4 da matsayi na karaya. Ana iya gano cewa mafi nisa daga layin rarraba ruwa mai sanyaya ruwa, ƙananan taurin ƙarshen ƙarewar da aka jinkirta. A lokaci guda kuma, wurin karyewar shima yana a ƙarshen inda taurin ya kasance mafi ƙanƙanta, raunin 86HB. Daga Table 2, an gano cewa kusan babu nakasar filastik a ƙarshen sanyin ruwa. Daga Table 1, an gano cewa aikin samfurin (ƙarfin ƙarfin 298MPa, yawan amfanin ƙasa 266MPa) yana raguwa sosai. Ƙarfin ƙarfi shine kawai 298MPa, wanda baya kaiwa ga ƙarfin samar da ƙarshen sanyaya ruwa (315MPa). Ƙarshen ya ƙirƙiri wuyansa lokacin da yake ƙasa da 315MPa. Kafin karaya, nakasar roba kawai ta faru a wurin da aka sanyaya ruwa. Yayin da damuwa ya ɓace, damuwa a ƙarshen ruwan sanyi ya ɓace. A sakamakon haka, adadin nakasa a cikin yanki mai sanyaya ruwa a cikin Table 2 ba shi da wani canji. Samfurin ya karya a ƙarshen jinkirin wutar lantarki, yankin da aka lalata ya ragu, kuma ƙarshen taurin shine mafi ƙasƙanci, yana haifar da raguwa mai yawa a sakamakon aikin.

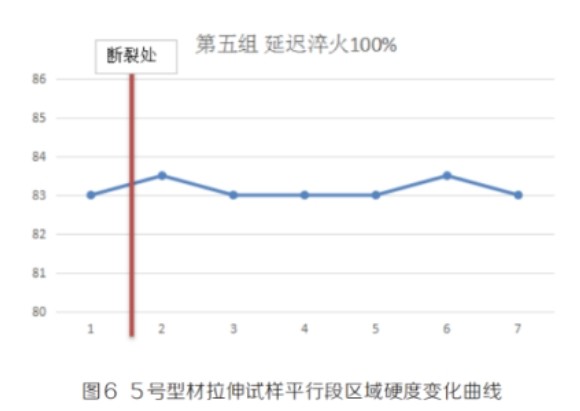

Ɗauki samfurori daga wurin da aka jinkirta 100% a ƙarshen samfurin 400mm. Hoto na 6 yana nuna madaidaicin taurin. An rage taurin sashin layi daya zuwa kusan 83-84HB kuma yana da inganci. Saboda wannan tsari, aikin yana kusan iri ɗaya ne. Ba a sami takamaiman tsari a wurin karyewar ba. Ayyukan gami yana ƙasa da na samfurin da aka kashe ruwa.

Don ƙara bincika daidaitaccen aiki da karaya, an zaɓi sashin layi ɗaya na samfurin tensile kusa da mafi ƙasƙanci na taurin (77HB). Daga Table 1, an gano cewa aikin ya ragu sosai, kuma raguwa ya bayyana a mafi ƙasƙanci na taurin a cikin Hoto 2.

2.3 Sakamakon bincike na ANSYS

Hoto na 7 yana nuna sakamakon simintin ANSYS na lanƙwan sanyi a wurare daban-daban. Ana iya ganin cewa zazzabi na samfurin a cikin wurin sanyaya ruwa ya ragu da sauri. Bayan 5s, zafin jiki ya ragu zuwa ƙasa da 100 ° C, kuma a 80mm daga layin rarraba, zafin jiki ya ragu zuwa kimanin 210 ° C a 90s. Matsakaicin raguwar zafin jiki shine 3.5°C/s. Bayan daƙiƙa 90 a cikin wurin sanyaya iska ta ƙarshe, zafin jiki yana raguwa zuwa kusan 360 ° C, tare da matsakaicin raguwar 1.9°C/s.

Ta hanyar nazarin aikin da sakamakon kwaikwayo, an gano cewa aikin wurin sanyaya ruwa da kuma jinkirin quenching yanki shine canjin canji wanda ya fara raguwa sannan ya karu kadan. Shafewar ruwan sanyi kusa da layin rarraba, zafin zafi yana haifar da samfurin a wani yanki ya faɗi a ƙimar sanyaya ƙasa da na sanyaya ruwa (3.5°C/s). Sakamakon haka, Mg2Si, wanda ya ƙarfafa cikin matrix, ya yi hazo da yawa a wannan yanki, kuma zafin jiki ya ragu zuwa kusan 210 ° C bayan daƙiƙa 90. Babban adadin Mg2Si hazo ya haifar da ƙaramin tasirin sanyaya ruwa bayan 90 s. Adadin lokacin ƙarfafawa na Mg2Si da aka haɓaka bayan an rage jinyar tsufa sosai, kuma aikin samfurin ya rage daga baya. Duk da haka, yankin da aka jinkirtar da ke nesa da layin rarraba ba shi da tasiri ta hanyar tafiyar da zafi mai sanyaya ruwa, kuma gawa yana yin sanyi a hankali a ƙarƙashin yanayin sanyaya iska (yawan sanyaya 1.9°C/s). Kadan daga cikin lokacin Mg2Si ne kawai ke hazo a hankali, kuma zafin jiki shine 360C bayan 90s. Bayan sanyaya ruwa, yawancin lokaci na Mg2Si har yanzu yana cikin matrix, kuma yana tarwatsewa da haɓakawa bayan tsufa, wanda ke taka rawar ƙarfafawa.

3. Kammalawa

An gano ta hanyar gwaje-gwaje cewa jinkirin quenching zai haifar da taurin yankin jinkirin kashewa a madaidaicin quenching na al'ada da jinkirta quenching don fara raguwa sannan kuma ya ƙara kaɗan har sai ya daidaita.

Domin 6061 aluminum gami, da tensile ƙarfi bayan al'ada quenching da kuma jinkirta quenching for 90 s ne 342MPa da 288MPa bi da bi, da yawan amfanin ƙasa ƙarfi ne 315MPa da 252MPa, dukansu biyu hadu da samfurin yi matsayin.

Akwai yanki mai taurin mafi ƙanƙanta, wanda aka rage daga 95HB zuwa 77HB bayan ƙarewar al'ada. Ayyukan a nan kuma shine mafi ƙanƙanta, tare da ƙarfin juriya na 271MPa da ƙarfin samar da 220MPa.

Ta hanyar nazarin ANSYS, an gano cewa yawan sanyaya a mafi ƙarancin aiki a cikin 90s jinkiri yankin quenching ya ragu da kusan 3.5°C a cikin sakan daya, yana haifar da rashin ingantaccen bayani na lokacin ƙarfafa lokaci na Mg2Si. A cewar wannan labarin, za a iya gani cewa yi hadarin batu bayyana a cikin jinkiri quenching yankin a junction na al'ada quenching da kuma jinkirta quenching, kuma ba da nisa daga junction, wanda yana da muhimmanci shiryarwa muhimmanci ga m riƙe extrusion wutsiya karshen aiwatar sharar gida.

May Jiang ta gyara daga MAT Aluminum

Lokacin aikawa: Agusta-28-2024