1. Gabatarwa

Aluminum alloys tare da matsakaicin ƙarfi suna nuna halaye masu kyau na sarrafawa, quenching hankali, taurin tasiri, da juriya na lalata. Ana amfani da su sosai a masana'antu daban-daban, kamar kayan lantarki da na ruwa, don kera bututu, sanduna, bayanan martaba, da wayoyi. A halin yanzu, ana samun karuwar buƙatun sandunan gami na aluminum 6082. Don saduwa da buƙatun kasuwa da buƙatun mai amfani, mun gudanar da gwaje-gwaje akan hanyoyin dumama extrusion daban-daban da hanyoyin magance zafi na ƙarshe don sandunan 6082-T6. Manufarmu ita ce gano tsarin kula da zafi wanda ya gamsar da buƙatun aikin injina na waɗannan sanduna.

2.Tsarin Gwaji da Ƙarfafa Tsarin Samfura

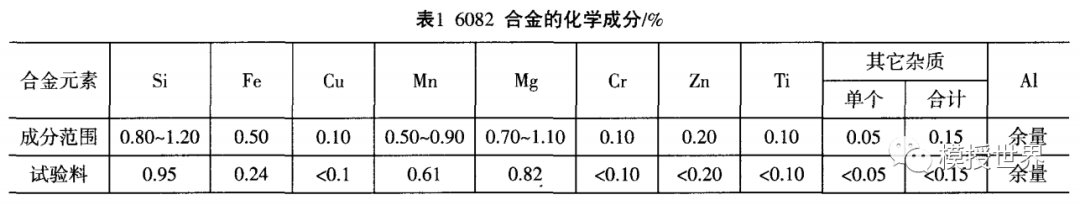

2.1 Abubuwan Gwaji

Simintin gyare-gyare na girman Ф162 × 500 an samar da su ta amfani da hanyar simintin ci gaba mai ci gaba kuma an ba da magani mara kyau. Ingancin ƙarfe na ingots ya dace da ƙa'idodin fasaha na sarrafa cikin gida na kamfani. An nuna nau'in sinadarai na alloy 6082 a cikin Table 1.

2.2 Tsari Tsari

Sandunan gwaji na 6082 suna da ƙayyadaddun ƙayyadaddun Ф14mm. Akwatin extrusion yana da diamita na Ф170mm tare da ƙirar 4-rami extrusion da ƙirar extrusion na 18.5. Ƙayyadadden tsari na gudana ya haɗa da dumama ingot, extrusion, quenching, mikewa madaidaiciya da samfurin, abin nadi madaidaiciya, yankan ƙarshe, tsufa na wucin gadi, dubawa mai inganci, da bayarwa.

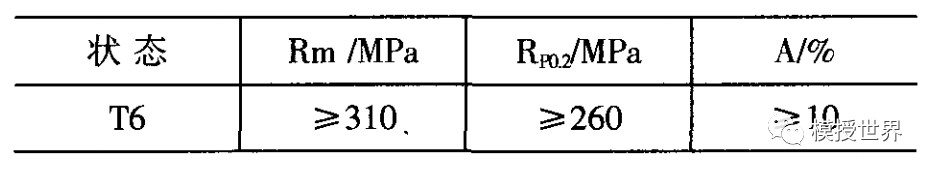

3.Manufofin Gwaji

Manufar wannan binciken shine don gano ma'auni na tsarin kula da zafi na extrusion da sigogin maganin zafi na ƙarshe waɗanda ke tasiri aikin sanduna 6082-T6, a ƙarshe cimma daidaitattun buƙatun aiki. Dangane da ka'idodi, kaddarorin injunan injin na 6082 ya kamata su dace da ƙayyadaddun bayanai da aka jera a cikin Table 2.

4.Tsarin Gwaji

4.1 Binciken Maganin Zafin Extrusion

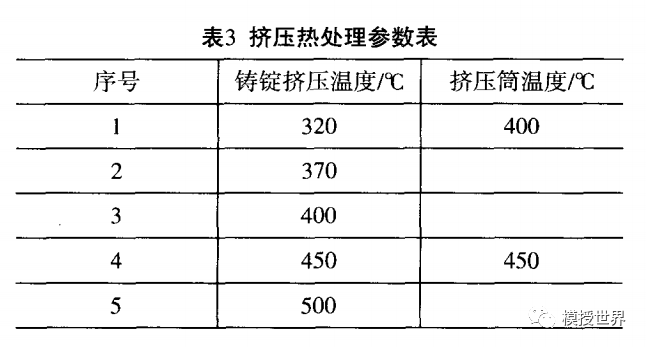

Binciken jiyya na zafi na extrusion da farko ya mai da hankali kan tasirin simintin ɗumbin zafin jiki da zafin jiki na extrusion akan kayan inji. An yi dalla-dalla dalla-dalla takamaiman zaɓen ma'auni a cikin Tebura 3.

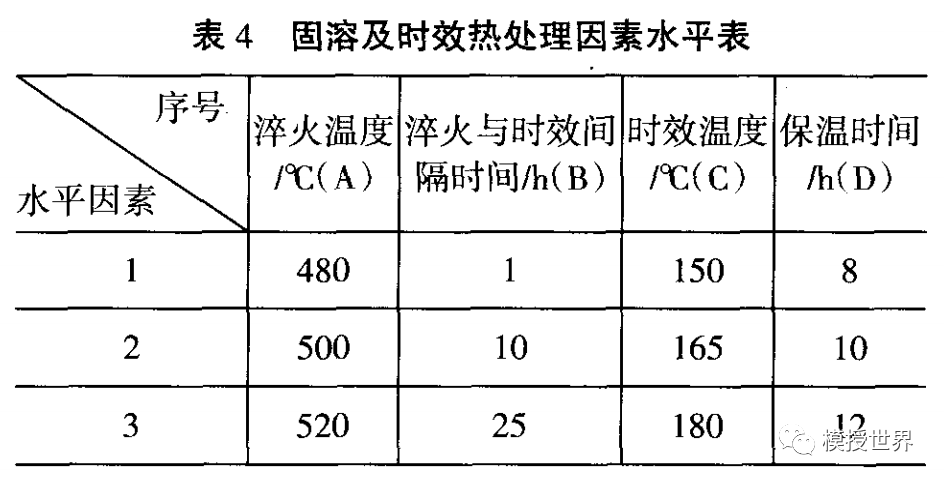

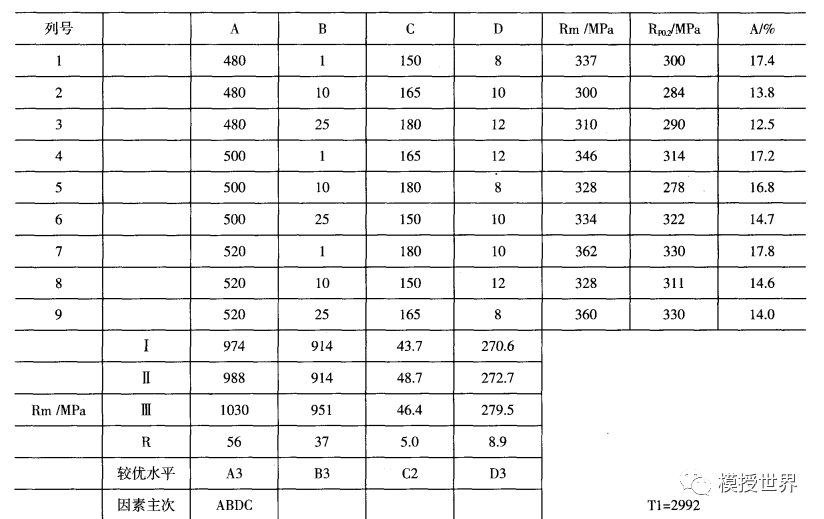

4.2 Magani mai ƙarfi da Binciken Maganin Zafin Tsufa

An yi amfani da ƙirar gwaji ta orthogonal don ingantaccen bayani da tsarin maganin zafi na tsufa. An samar da matakan da aka zaɓa a cikin Tebur 4, tare da tebur ɗin ƙira na orthogonal wanda aka nuna azaman IJ9(34).

5.Sakamako da Nazari

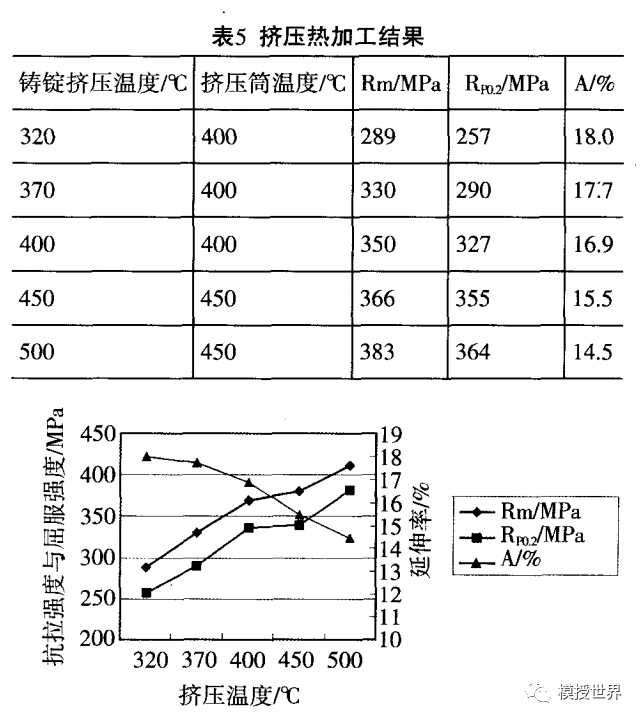

5.1 Sakamako da Nazari na Gwajin Maganin Zafin Extrusion

An gabatar da sakamakon gwaje-gwajen gwaje-gwajen zafi na extrusion a cikin Table 5 da Hoto 1. An dauki samfurori tara ga kowane rukuni, kuma an ƙayyade ma'auni na aikin injiniya. Dangane da bincike na metallographic da sinadaran sinadaran, an kafa tsarin kula da zafi: quenching a 520 ° C na minti 40 da tsufa a 165 ° C na 12 hours. Daga Table 5 da Hoto 1, ana iya lura da cewa yayin da simintin gyare-gyaren ingot zafin jiki da zafin jiki na extrusion ya karu, ƙarfin juzu'i da ƙarfin amfanin gona ya karu a hankali. An sami sakamako mafi kyau a yanayin zafi na 450-500 ° C da zafin jiki na extrusion na 450 ° C, wanda ya cika daidaitattun bukatu. Wannan ya faru ne saboda tasirin aikin sanyi a ƙananan zafin jiki na extrusion, yana haifar da karyewar iyakokin hatsi da kuma ƙara ƙaƙƙarfan bazuwar bayani tsakanin A1 da Mn yayin dumama kafin quenching, wanda ke haifar da recrystallization. Yayin da zafin jiki na extrusion ya karu, ƙarfin ƙarshe na Rm na samfurin ya inganta sosai. Lokacin da kwandon zafin jiki ya kusanci ko ya wuce zafin da aka samu, nakasar da ba ta dace ba ta ragu, yana rage zurfin zoben hatsi da ƙara ƙarfin amfanin gona Rm. Don haka, ma'auni masu ma'ana don maganin zafi na extrusion sune: ingot extrusion zafin jiki na 450-500 ° C da extrusion kwandon zafin jiki na 430-450 ° C.

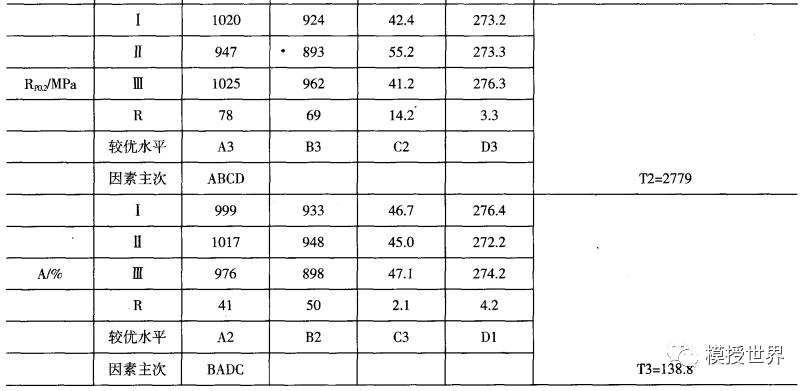

5.2 M Magani da Tsufa Sakamakon Gwaji na Orthogonal da Bincike

Tebur na 6 ya bayyana cewa mafi kyawun matakan shine A3B1C2D3, tare da kashewa a 520 ° C, zafin jiki na wucin gadi tsakanin 165-170 ° C, da tsawon lokacin tsufa na sa'o'i 12, yana haifar da babban ƙarfi da filastik na sanduna. A quenching tsari Forms supersaturated m bayani. A ƙananan quenching yanayin zafi, taro na supersaturated m bayani yana raguwa, yana tasiri ƙarfi. Matsakaicin zafin jiki na kusan 520°C yana haɓaka tasirin ingantaccen bayani mai ƙarfi wanda ke haifar da kashewa. Tazara tsakanin quenching da tsufa na wucin gadi, watau, ajiyar zafin jiki na ɗaki, yana rinjayar kaddarorin inji. Ana kiran wannan musamman ga sandunan da ba a shimfiɗa su bayan an kashe su. Lokacin da tazara tsakanin quenching da tsufa ya wuce awa 1, ƙarfi, musamman ƙarfin amfanin gona, yana raguwa sosai.

5.3 Binciken Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararru

An gudanar da bincike mai girma da ƙima akan sanduna 6082-T6 a ingantaccen yanayin zafi na 520°C da 530°C. Hotuna masu girma da yawa sun bayyana hazo na gama gari tare da ɗimbin ɓangarorin lokaci masu hazo da aka rarraba daidai gwargwado. Binciken haske na Polarized ta amfani da kayan aikin Axiovert200 ya nuna bambance-bambance daban-daban a cikin hotuna tsarin hatsi. Yankin tsakiya ya nuna ƙananan hatsi iri-iri, yayin da gefuna suka nuna wasu recrystallization tare da tsayin hatsi. Wannan ya faru ne saboda haɓakar ƙwayoyin kristal a yanayin zafi mai yawa, waɗanda ke haifar da ƙananan allura kamar hazo.

6.Production Practice Assessment

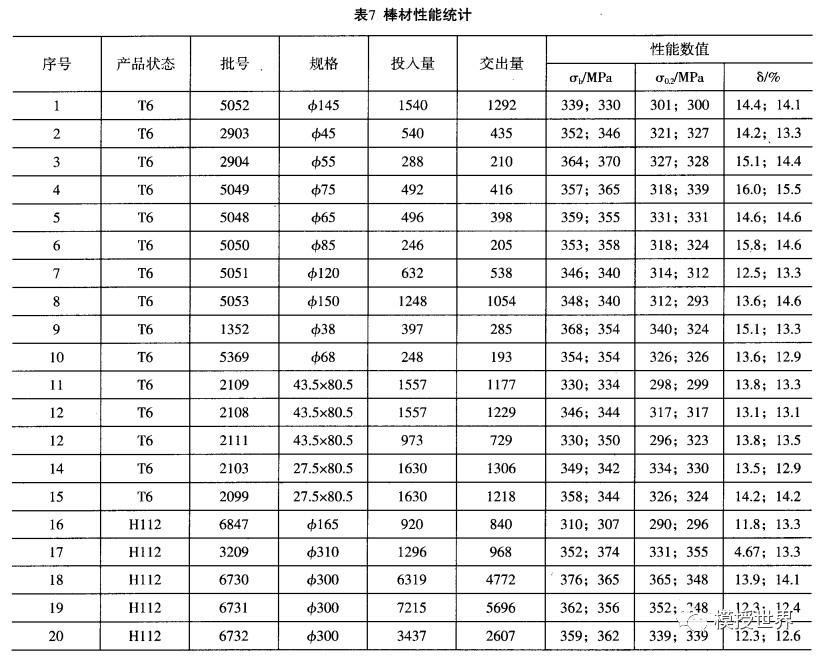

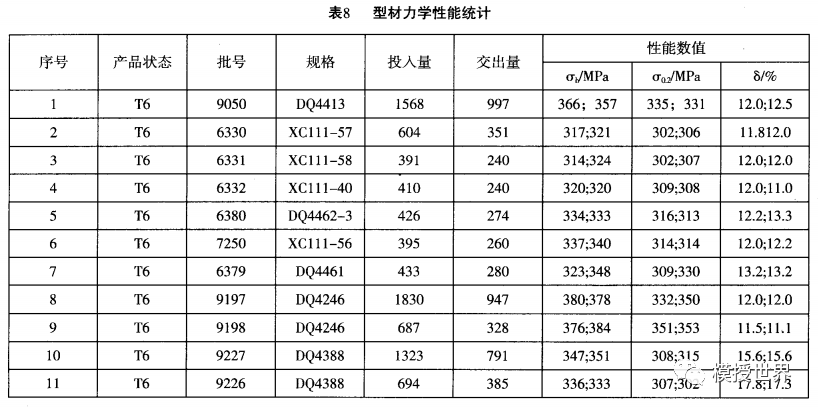

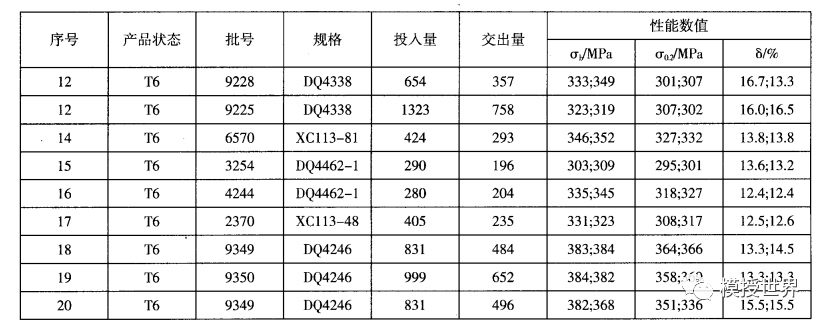

A cikin ainihin samarwa, an gudanar da kididdigar aikin injiniya akan batches 20 na sanduna da batches 20 na bayanan martaba. Ana nuna sakamakon a cikin Tables 7 da 8. A cikin ainihin samarwa, an aiwatar da tsarin mu na extrusion a yanayin zafi wanda ya haifar da samfurori na jihar T6, kuma aikin injiniya ya sadu da ƙididdiga masu mahimmanci.

7.Kammalawa

(1) Matsalolin maganin zafi mai zafi: Ingots zafin jiki na 450-500 ° C; extrusion kwandon zafin jiki na 430-450 ° C.

(2) Matsalolin maganin zafi na ƙarshe: Mafi kyawun zafin jiki mai ƙarfi na 520-530 ° C; zafin jiki na tsufa a 165 ± 5 ° C, tsawon lokacin tsufa na sa'o'i 12; Tazara tsakanin quenching da tsufa bai kamata ya wuce awa 1 ba.

(3) Dangane da kima mai amfani, tsarin kula da zafi mai yuwuwa ya haɗa da: zafin jiki na extrusion na 450-530 ° C, kwandon zafin jiki na 400-450 ° C; m zafin jiki bayani na 510-520 ° C; tsarin tsufa na 155-170 ° C na sa'o'i 12; babu takamaiman iyaka akan tazara tsakanin quenching da tsufa. Ana iya shigar da wannan cikin jagororin aiki.

May Jiang ta gyara daga MAT Aluminum

Lokacin aikawa: Maris 15-2024