Idan kayan aikin injiniya na extrusions ba su kasance kamar yadda ake tsammani ba, yawanci ana mayar da hankali kan abun da ke cikin billet ko yanayin extrusion / tsufa. Mutane kaɗan suna tambayar ko homogenization kanta na iya zama batun. A gaskiya ma, matakin homogenization yana da mahimmanci don samar da extrusions masu inganci. Rashin yadda ya kamata sarrafa matakin homogenization na iya haifar da:

●Ƙara matsa lamba

●Ƙarin lahani

●Sanya laushi bayan anodizing

●Ƙananan saurin extrusion

●Kayan kayan aikin injiniya mara kyau

Matakin homogenization yana da manyan dalilai guda biyu: tace ƙarfe mai ƙunshe da mahaɗan intermetallic, da sake rarraba magnesium (Mg) da silicon (Si). Ta hanyar nazarin microstructure na billet kafin da kuma bayan homogenization, wanda zai iya hango ko hasashen ko billet zai yi kyau a lokacin extrusion.

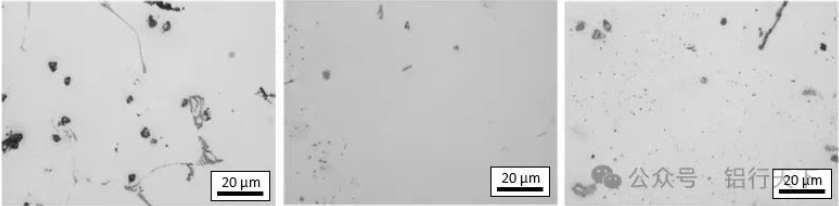

Tasirin Billet Homogenization akan Hardening

A cikin 6XXX extrusions, ƙarfi yana fitowa daga matakan Mg- da Si-rich da aka kafa yayin tsufa. Ikon samar da waɗannan matakan ya dogara ne akan sanya abubuwan cikin ingantaccen bayani kafin tsufa ya fara. Don Mg da Si su zama wani ɓangare na ingantaccen bayani, dole ne a kashe ƙarfe da sauri daga sama da 530 ° C. A yanayin zafi sama da wannan batu, Mg da Si suna narkar da su cikin aluminium. Duk da haka, a lokacin extrusion, karfen yana tsayawa sama da wannan zafin jiki na ɗan gajeren lokaci. Don tabbatar da duk Mg da Si sun narke, ƙwayoyin Mg da Si suna buƙatar zama ƙanana. Abin takaici, yayin yin simintin gyare-gyare, Mg da Si suna yin hazo kamar manyan tubalan Mg₂Si (Fig. 1a).

A al'ada homogenization sake zagayowar na 6060 billets ne 560 ° C na 2 hours. A lokacin wannan tsari, tun da billet ɗin ya kasance sama da 530 ° C na dogon lokaci, Mg₂Si yana narkewa. Bayan sanyaya, yana sake haɓakawa a cikin rarraba mafi kyau (Fig. 1c). Idan yawan zafin jiki na homogenization bai isa ba, ko kuma lokacin ya yi guntu sosai, wasu manyan ƙwayoyin Mg₂Si za su kasance. Lokacin da wannan ya faru, ingantaccen bayani bayan extrusion yana ƙunshe da ƙarancin Mg da Si, yana sa ba zai yuwu a samar da babban adadin hardening precipitates-wanda ke haifar da raguwar kaddarorin inji.

Hoto 1. Na'urorin gani na gani na gogewa da 2% HF-etched 6060 billlets: (a) simintin simintin gyare-gyare, (b) an haɗa shi da wani yanki, (c) cikakke mai kama da juna.

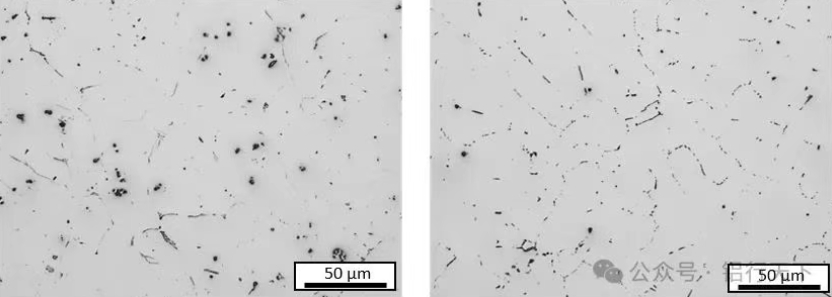

Matsayin Homogenization akan Intermetallics mai ɗauke da ƙarfe

Iron (Fe) yana da tasiri mafi girma akan taurin karye fiye da kan ƙarfi. A cikin 6XXX alloys, matakan Fe suna kan samar da β-phase (Al₅(FeMn)Si ko Al₈.₉(FeMn)₂Si₂) yayin yin simintin. Wadannan matakan suna da girma, angular, kuma suna tsoma baki tare da extrusion (wanda aka haskaka a cikin Fig. 2a). A lokacin homogenization, abubuwa masu nauyi (Fe, Mn, da dai sauransu) suna yaduwa, kuma manyan sassan kusurwa sun zama karami da zagaye (Fig. 2b).

Daga hotuna na gani kadai, yana da wuya a iya bambanta matakai daban-daban, kuma ba shi yiwuwa a dogara da su. A Innoval, muna ƙididdige ƙididdige lissafin billet ta amfani da hanyar gano fasalin ciki da kuma rarrabuwa (FDC), wanda ke ba da ƙimar % α don billet. Wannan yana ba mu damar tantance ingancin homogenization.

Hoto 2. Na gani micrographs na billets (a) kafin da (b) bayan homogenization.

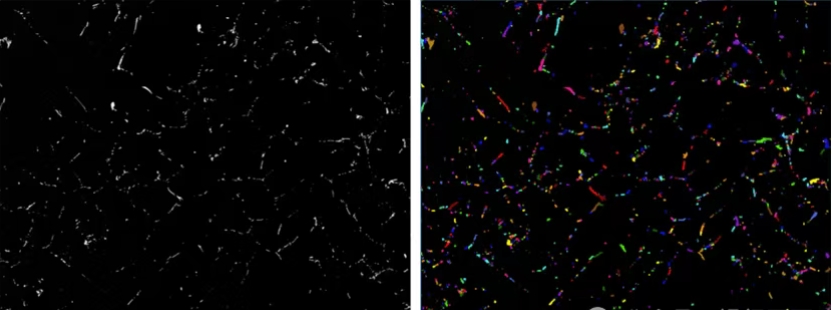

Hanyar Ganewa da Rarraba (FDC).

Hoto na 3a yana nuna samfurin goge-goge da aka bincika ta hanyar duban microscopy na lantarki (SEM). Sa'an nan kuma ana amfani da dabarar maƙasudin bakin toka don rarrabewa da gano abubuwan tsaka-tsaki, waɗanda suka bayyana fari a hoto na 3b. Wannan dabarar tana ba da damar bincika wuraren har zuwa 1 mm², ma'ana sama da fasalulluka 1000 ana iya tantance su lokaci ɗaya.

Hoto 3. (a) Hoton electron da aka watsar na billet 6060 mai kama da juna, (b) an gano sifofin mutum ɗaya daga (a).

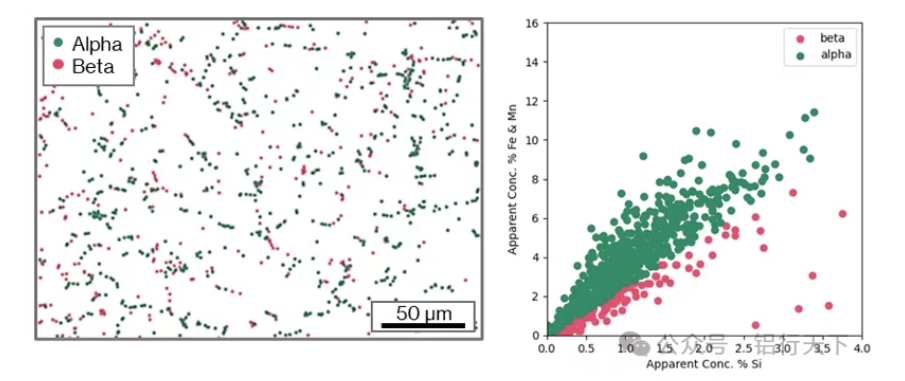

Haɗin Barbashi

Tsarin Innoval yana sanye da na'urar ganowa ta Oxford Instruments Xplore 30 mai tarwatsawar makamashi (EDX). Wannan yana ba da damar tarin bakan EDX ta atomatik ta atomatik daga kowane wurin da aka gano. Daga waɗannan bakan, za'a iya ƙayyade abun da ke cikin barbashi, kuma an ƙididdige ƙa'idar Fe: Si.

Dangane da abun ciki na Mn ko Cr na gami, ana iya haɗa wasu abubuwa masu nauyi kuma. Ga wasu allunan 6XXX (wani lokaci tare da Mn mai mahimmanci), ana amfani da (Fe + Mn): Si rabo azaman tunani. Ana iya kwatanta waɗannan ma'auni da na sananniyar Fe-dauke da intermetallics.

β-phase (Al₅ (FeMn) Si ko Al₈.₉ (FeMn)₂Si₂): (Fe+Mn): Si rabo ≈ 2. α-phase (Al₁₂(FeMn)₃Si ko Al₈.₃(FeMn):–6, dangane da abun da ke ciki. Software na mu na al'ada yana ba mu damar saita ƙofa da rarraba kowane barbashi azaman α ko β, sa'an nan kuma taswirar matsayinsu a cikin ƙananan ƙwayoyin cuta (Fig. 4). Wannan yana ba da kusan kashi na canza α a cikin billet ɗin da aka yi kama da juna.

Hoto 4. (a) Taswirar da ke nuna α- da β-classified particles, (b) tarwatsa shirin (Fe+Mn): Si rabo.

Abin da Data Iya Fada Mana

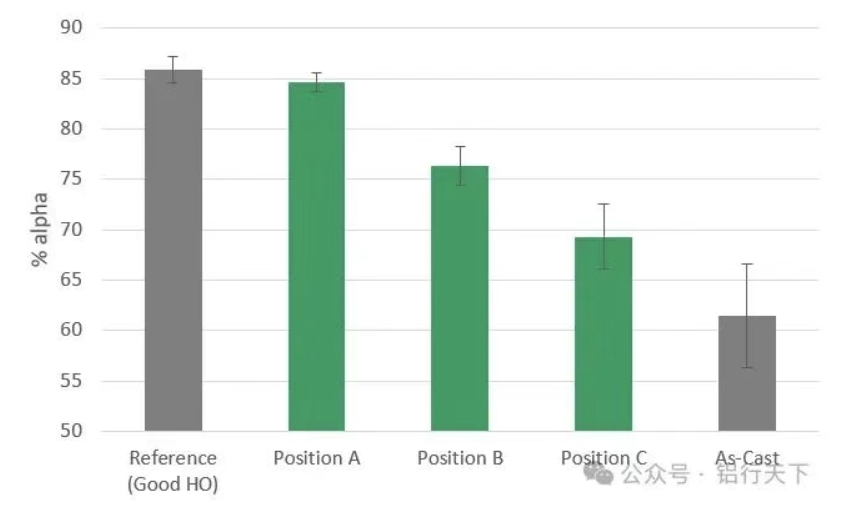

Hoto na 5 yana nuna misalin yadda ake amfani da wannan bayanin. A wannan yanayin, sakamakon yana nuna ɗumamar da ba ta dace ba a cikin takamaiman tanderun wuta, ko yuwuwar ba a kai ma'aunin zafin jiki ba. Don tantance irin waɗannan shari'o'in da kyau, ana buƙatar billet ɗin gwaji da takaddun shaida na sanannun inganci. Idan ba tare da waɗannan ba, ba za a iya kafa kewayon %α da ake tsammani don wannan abun da ke ciki ba.

Hoto 5. Kwatanta %α a cikin sassa daban-daban na tanderun da ba ya aiki mara kyau.

Lokacin aikawa: Agusta-30-2025