Ana amfani da gwajin ƙarfin ƙarfi don ƙayyade ikon kayan ƙarfe don tsayayya da lalacewa yayin tsarin shimfidawa, kuma yana ɗaya daga cikin mahimman alamomi don kimanta kayan aikin injiniya na kayan.

1. Gwajin juzu'i

Gwajin juzu'i ya dogara ne akan ka'idodin injiniyoyi na kayan aiki. Ta hanyar yin amfani da kayan aiki mai mahimmanci ga samfurin kayan aiki a ƙarƙashin wasu sharuɗɗa, yana haifar da lalacewa har sai samfurin ya karya. A lokacin gwajin, nakasar samfurin gwaji a ƙarƙashin nau'o'i daban-daban da matsakaicin nauyin lokacin da aka yi rikodin samfurin samfurin, don ƙididdige ƙarfin yawan amfanin ƙasa, ƙarfin ƙarfi da sauran alamun aikin kayan aiki.

Danniya σ = F/A

σ shine ƙarfin tensile (MPa)

F shine nauyi mai ƙarfi (N)

A shine yanki na yanki na samfurin

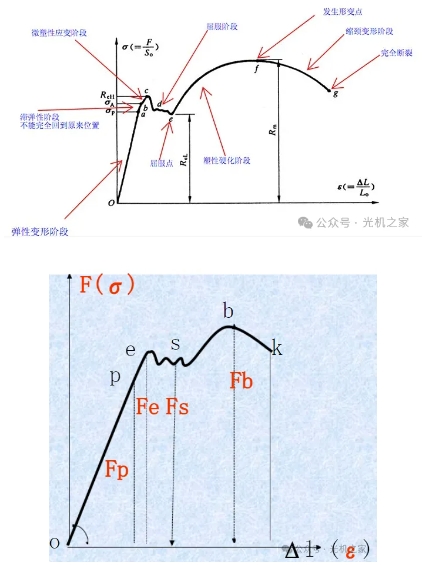

2. Lanƙwan ƙarfi

Binciken matakai da yawa na tsarin shimfidawa:

a. A cikin mataki na OP tare da ƙananan kaya, ƙaddamarwa yana cikin dangantaka mai layi tare da kaya, kuma Fp shine matsakaicin nauyin don kula da madaidaiciyar layi.

b. Bayan lodin ya wuce Fp, lanƙwan ƙwanƙwasa ya fara ɗaukar alaƙar da ba ta kai tsaye ba. Samfurin ya shiga matakin nakasawa na farko, kuma an cire kaya, kuma samfurin zai iya komawa matsayinsa na asali kuma ya lalata.

c. Bayan nauyin ya wuce Fe, an cire nauyin, an sake dawo da wani ɓangare na nakasar, kuma ana riƙe wani ɓangare na nakasar da ta rage, wanda ake kira nakasar filastik. Fe ana kiransa iyaka na roba.

d. Lokacin da nauyin ya ƙara ƙaruwa, lanƙwan juzu'i yana nuna sawtooth. Lokacin da nauyin ba ya karuwa ko raguwa, abin da ke faruwa na ci gaba da haɓaka samfurin gwaji ana kiransa samar da albarkatu. Bayan samar da samfur, samfurin zai fara fuskantar nakasar filastik a bayyane.

e. Bayan da aka ba da kyauta, samfurin yana nuna karuwa a cikin juriya na lalacewa, aiki mai ƙarfi da ƙarfafa nakasawa. Lokacin da kaya ya kai Fb, ɓangaren samfurin yana raguwa sosai. Fb shine iyakar ƙarfi.

f. Abin mamaki na raguwa yana haifar da raguwa a cikin ƙarfin ɗaukar samfurin. Lokacin da kaya ya kai Fk, samfurin ya karya. Ana kiran wannan nauyin karaya.

Ƙarfin Haɓaka

Ƙarfin haɓakawa shine matsakaicin ƙimar danniya wanda kayan ƙarfe zai iya jurewa daga farkon nakasar filastik don kammala karaya lokacin da aka yi wa ƙarfin waje. Wannan ƙimar tana nuna mahimmancin mahimmanci inda kayan ke canzawa daga matakin nakasawa na roba zuwa matakin nakasar filastik.

Rabewa

Ƙarfin yawan amfanin ƙasa: yana nufin matsakaicin danniya na samfurin kafin ƙarfin ya faɗo a karon farko lokacin da samari ya faru.

Ƙarfin yawan amfanin ƙasa: yana nufin mafi ƙarancin damuwa a matakin yawan amfanin ƙasa lokacin da aka yi watsi da tasirin wucin gadi na farko. Tun da darajar ƙananan ma'aunin yawan amfanin ƙasa yana da ingantacciyar tsayayye, yawanci ana amfani dashi azaman mai nuna juriya na abu, wanda ake kira ma'anar yawan amfanin ƙasa ko ƙarfin yawan amfanin ƙasa.

Ƙididdigar ƙididdiga

Don ƙarfin yawan amfanin ƙasa: R = F / Sₒ, inda F shine matsakaicin ƙarfi kafin ƙarfin ya faɗo a karon farko a matakin yawan amfanin ƙasa, kuma Sₒ shine ainihin yanki na giciye na samfurin.

Don ƙananan ƙarfin amfanin ƙasa: R = F / Sₒ, inda F shine mafi ƙarancin ƙarfin F yana watsi da tasirin wucin gadi na farko, kuma Sₒ shine ainihin yanki na yanki na samfurin.

Naúrar

Ƙarfin yawan amfanin ƙasa yawanci MPa (megapascal) ko N/mm² (Newton a kowace murabba'in millimeter).

Misali

Ɗauki ƙananan ƙarfe na carbon a matsayin misali, iyakar yawan amfanin sa yawanci 207MPa. Lokacin da aka yi wa wani ƙarfi na waje wanda ya fi wannan iyaka, ƙananan ƙarfe na carbon zai haifar da nakasawa na dindindin kuma ba za a iya dawo da shi ba; lokacin da aka yi wa wani ƙarfi na waje ƙasa da wannan iyaka, ƙananan ƙarfe na carbon zai iya komawa zuwa asalinsa.

Ƙarfin amfanin gona yana ɗaya daga cikin mahimman alamomi don kimanta kayan aikin injiniya na kayan ƙarfe. Yana nuna ikon kayan don tsayayya da nakasar filastik lokacin da aka yi wa sojojin waje.

Ƙarfin ƙarfi

Tenarfin tenerile shine ikon kayan don tsayayya da lalacewa a ƙarƙashin nauyin da ke cikin tensile, wanda aka bayyana takamaiman darajar abin da kayan zai iya tsayayya da kayan aikin. Lokacin da danniya a kan kayan ya wuce ƙarfin ƙarfinsa, kayan za su fuskanci nakasar filastik ko karaya.

Ƙididdigar ƙididdiga

Ƙididdigar ƙididdiga don ƙarfin ɗaure (σt) shine:

σt = F / A

Inda F shine matsakaicin ƙarfi mai ƙarfi (Newton, N) wanda samfurin zai iya jurewa kafin ya karye, kuma A shine asalin yanki na yanki na samfurin (milimita murabba'in, mm²).

Naúrar

Naúrar ƙarfin ƙarfi yawanci MPa (megapascal) ko N/mm² (Newton a kowace murabba'in millimeter). 1 MPa daidai yake da Newtons 1,000,000 a kowace murabba'in mita, wanda kuma yayi daidai da 1 N/mm².

Abubuwa masu tasiri

Ƙarfin ƙwanƙwasa yana shafar abubuwa da yawa, ciki har da sinadaran sinadaran, microstructure, tsarin kula da zafi, hanyar sarrafawa, da dai sauransu Kayan aiki daban-daban suna da nau'i daban-daban, don haka a cikin aikace-aikacen aiki, ya zama dole don zaɓar kayan da suka dace bisa ga kayan aikin injiniya na kayan.

Aikace-aikace na aiki

Ƙarfin juzu'i muhimmin ma'auni ne mai mahimmanci a fagen kimiyyar kayan aiki da injiniyanci, kuma galibi ana amfani da shi don kimanta halayen injiniyoyi na kayan. Dangane da tsarin tsari, zaɓin kayan, ƙimar aminci, da dai sauransu, ƙarfin ɗaure wani abu ne wanda dole ne a yi la'akari da shi. Alal misali, a aikin injiniyan gine-gine, ƙarfin daɗaɗɗen ƙarfe yana da mahimmanci wajen ƙayyade ko zai iya jurewa lodi; a fagen sararin samaniya, ƙarfin juzu'i na kayan nauyi da ƙarfi shine mabuɗin don tabbatar da amincin jirgin sama.

Ƙarfin gajiya:

Gaji na ƙarfe yana nufin tsarin da kayan aiki da kayan aikin a hankali ke haifar da lahani na dindindin na gida a ɗaya ko wurare da yawa ƙarƙashin damuwa na cyclic ko nau'in cyclic, da tsagewa ko cikakkiyar karaya kwatsam bayan wasu adadin zagayowar.

Siffofin

Kwatsam a cikin lokaci: Rashin gajiyar ƙarfe yakan faru ba zato ba tsammani a cikin ɗan gajeren lokaci ba tare da alamun bayyanar ba.

Wurin zama a matsayi: Rashin gajiya yakan faru a yankunan gida inda damuwa ya taru.

Hankali ga muhalli da lahani: gajiyar ƙarfe tana da matukar kula da muhalli da ƙananan lahani a cikin kayan, waɗanda zasu iya haɓaka aikin gajiya.

Abubuwa masu tasiri

Girman damuwa: Girman damuwa kai tsaye yana shafar rayuwar gajiyar ƙarfe.

Matsakaicin girman danniya: Mafi girman matsakaicin danniya, gajeriyar rayuwar gajiyar karfe.

Yawan zagayowar: Yawan lokutan ƙarfen yana ƙarƙashin matsin lamba ko ƙunci, mafi munin tarin lalacewar gajiya.

Matakan rigakafi

Haɓaka zaɓin abu: Zaɓi kayan da ke da iyakacin gajiya.

Rage ƙaddamar da damuwa: Rage ƙaddamar da damuwa ta hanyar ƙirar tsari ko hanyoyin sarrafawa, kamar yin amfani da jujjuyawar kusurwa mai zagaye, ƙara girman sassa, da sauransu.

Maganin saman: goge-goge, fesa, da sauransu akan saman ƙarfe don rage lahani da inganta ƙarfin gajiya.

Dubawa da kiyayewa: A kai a kai duba kayan aikin ƙarfe don ganowa da gyara lahani da sauri kamar fasa; kula da sassa masu saurin gajiya, kamar su maye gurbin sawa sassa da ƙarfafa raƙuman hanyoyin haɗin gwiwa.

Rashin gajiyar ƙarfe shine yanayin gazawar ƙarfe na gama gari, wanda ke siffanta kwatsam, wurin zama da hankali ga muhalli. Girman damuwa, matsakaita girman danniya da yawan hawan keke sune manyan abubuwan da ke shafar gajiyar ƙarfe.

SN curve: ya kwatanta rayuwar gajiyar kayan aiki a ƙarƙashin matakan damuwa daban-daban, inda S ke wakiltar damuwa kuma N yana wakiltar adadin hawan damuwa.

Ƙarfin ƙarfin gajiyawa:

(Kf = Ka \cdot Kb \cdot Kc \cdot Kd \cdot Ke)

Inda (Ka) shine ma'aunin kaya, (Kb) shine ma'aunin girman, (Kc) shine ma'aunin zafin jiki, (Kd) ma'aunin ingancin yanayin, kuma (Ke) shine abin dogaro.

Maganar lissafi na lanƙwasa SN:

(\sigma^m N = C)

Inda (\ sigma) yake damuwa, N shine adadin zagayowar damuwa, kuma m da C sune madaidaicin abu.

Matakan lissafin

Ƙayyade madaidaitan kayan:

Ƙayyade ƙimar m da C ta hanyar gwaje-gwaje ko ta hanyar nuni ga wallafe-wallafen da suka dace.

Ƙayyade ma'auni mai mahimmanci: Yi la'akari da ainihin siffar da girman ɓangaren, da kuma ƙaddamar da damuwa da ke haifar da fillet, keyways, da dai sauransu, don ƙayyade ƙarfin damuwa K. Ƙididdigar ƙarfin gajiya: Bisa ga SN curve da damuwa mai mahimmanci, hade tare da rayuwar zane da kuma aiki matakin damuwa na sashi, ƙididdige ƙarfin gajiya.

2. Filastik:

Plasticity yana nufin kadarorin abu wanda, lokacin da aka sa shi da ƙarfi na waje, yana haifar da nakasu na dindindin ba tare da karyewa ba lokacin da ƙarfin waje ya wuce iyakarsa na roba. Wannan nakasawa ba zai iya jurewa ba, kuma kayan ba zai dawo zuwa ainihin siffarsa ba ko da an cire ƙarfin waje.

Fihirisar Plasticity da tsarin lissafin sa

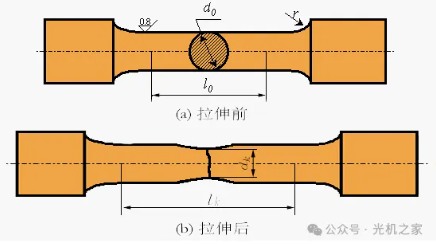

Tsawaitawa (δ)

Ma'anar: Tsawaitawa shine adadin jimillar nakasar sashin ma'auni bayan samfurin ya karye zuwa tsawon ma'aunin asali.

Formula: δ = (L1 – L0) / L0 × 100%

Inda L0 shine ainihin tsawon ma'auni na samfurin;

L1 shine tsayin ma'auni bayan an karya samfurin.

Rage sassa (Ψ)

Ma'anar: Rage raguwa shine kashi na matsakaicin matsakaicin raguwa a cikin yanki na giciye a wuyan wuyansa bayan samfurin ya karye zuwa yanki na asali na asali.

Formula: Ψ = (F0 – F1) / F0 × 100%

Inda F0 shine asalin yanki na yanki na samfurin;

F1 shine yanki na giciye a wurin wuyan wuyan bayan an karye samfurin.

3. Tauri

Ƙarfe taurin ƙaƙƙarfan ƙayyadaddun kayan inji don auna taurin kayan ƙarfe. Yana nuna ikon yin tsayayya da nakasawa a cikin ƙarar gida akan farfajiyar ƙarfe.

Rarrabewa da wakilcin taurin ƙarfe

Taurin ƙarfe yana da nau'ikan rarrabuwa da hanyoyin wakilci bisa ga hanyoyin gwaji daban-daban. Ya ƙunshi abubuwa masu zuwa:

Brinell hardness (HB):

Iyakar aikace-aikace: Gabaɗaya ana amfani dashi lokacin da kayan ya yi laushi, kamar ƙarfe mara ƙarfe, ƙarfe kafin maganin zafi ko bayan annealing.

Ƙa'idar gwaji: Tare da ƙayyadaddun nauyin nauyin gwajin, ana danna ƙwallon ƙarfe mai taurara ko ƙwallon carbide na wani diamita a cikin saman karfen da za a gwada, kuma za'a sauke nauyin bayan ƙayyadadden lokaci, kuma ana auna diamita na shigarwa a saman da za a gwada.

Ƙididdigar ƙididdiga: Ƙimar taurin Brinell ita ce ƙimar da aka samu ta hanyar rarraba kaya ta wurin sararin samaniya na indentation.

Rockwell hardness (HR):

Iyakar aikace-aikacen: Gabaɗaya ana amfani da su don kayan tare da taurin mafi girma, kamar taurin bayan maganin zafi.

Ƙa'idar gwaji: kama da taurin Brinell, amma ta yin amfani da bincike daban-daban (lu'u-lu'u) da hanyoyin lissafi daban-daban.

Nau'o'i: Dangane da aikace-aikacen, akwai HRC (don kayan aiki mai ƙarfi), HRA, HRB da sauran nau'ikan.

Vickers hardness (HV):

Iyalin aikace-aikacen: Ya dace da nazarin microscope.

Ƙa'idar gwaji: Latsa saman kayan tare da nauyin ƙasa da 120kg da mazugi mai murabba'in lu'u-lu'u tare da kusurwar tsaye na 136 °, kuma raba yankin saman rami na shigar da kayan ta ƙimar kaya don samun ƙimar taurin Vickers.

Tauri (HL):

Fasaloli: Gwajin taurin mai ɗaukar nauyi, mai sauƙin aunawa.

Ƙa'idar gwaji: Yi amfani da billa da aka yi ta hanyar tasirin ƙwallon ƙafa bayan yin tasiri akan saman taurin, kuma ƙididdige taurin ta hanyar rabon saurin dawowa na naushi a 1mm daga saman samfurin zuwa saurin tasiri.

Lokacin aikawa: Satumba-25-2024