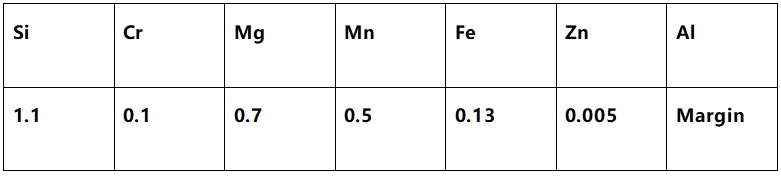

1. Alloy abun da ke ciki

2. Tsarin Homogenization

390 ℃ x rufi don 1.0h + 575 ℃ x rufi don 8h, iska mai ƙarfi mai sanyaya zuwa 200 ℃ sannan sanyaya ruwa.

3. Tsarin Metallographic

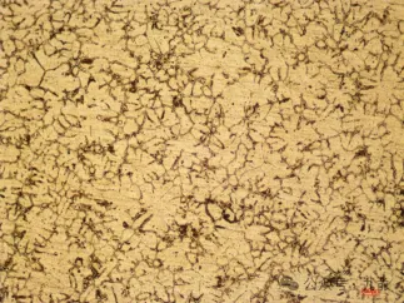

Hoto 1 Tsarin Metallographic na ainihin 6082 alloy ingot, wanda Keller reagent ya tsara, tare da ingantattun dendrites.

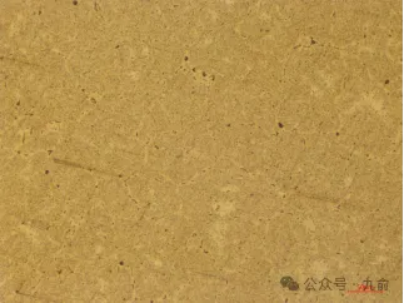

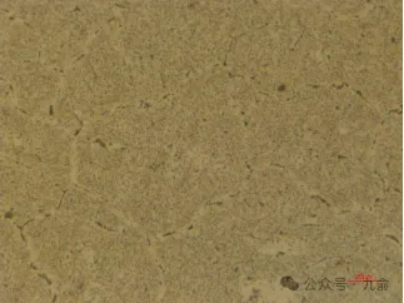

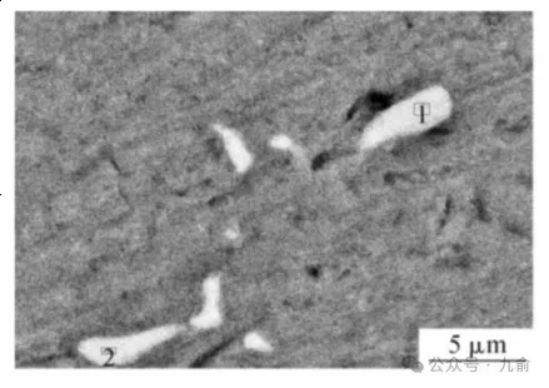

Hoto 2 Tsarin Metallographic na ainihin 6082 alloy ingot, wanda Keller reagent ya tsara, da tsari bayan ingantaccen bayani.

4. Sakamakon maganin zafi na homogenization akan tsarin gami

4.1 Kamar yadda aka nuna a Hoto 1, gami yana da ingantattun dendrites a cikin simintin simintin gyare-gyare, kuma akwai adadi mai yawa na hanyoyin hazo marasa daidaituwa na hanyar sadarwa a iyakokin hatsi.

4.2 Tun da narke maki na daban-daban abubuwa ne daban-daban a lokacin da gami solidifies, wannan jeri solidification sabon abu kai ga m solute abun da ke ciki a cikin crystal, wanda aka bayyana musamman a cikin ƙarni na babban adadin cibiyar sadarwa hazo bulan a hatsi iyakoki.

4.3 A cikin microstructure bayan maganin homogenization (Hoto 2), adadin matakan da aka haɓaka a kan iyakokin hatsi yana raguwa sosai, kuma girman hatsi yana ƙaruwa tare. Wannan saboda ana haɓaka yaduwar kwayoyin halitta a ƙarƙashin matsanancin zafin jiki, kawar da rabuwa da rashin daidaituwar lokaci yana faruwa a cikin ingot, kuma mahadi na cibiyar sadarwa akan iyakokin hatsi suna narkar da wani bangare.

4.4 Ta hanyar bincike na SEM, kamar yadda aka nuna a cikin FIG3, an zaɓi sassa daban-daban na lokacin da aka ƙaddara don nazarin EDS, yana tabbatar da cewa lokaci mai mahimmanci shine Al (MnFe) Si.

4.5 A yayin yin simintin gwal, babban adadin lokacin hazo mai ɗauke da Mn yana samuwa, kuma ana riƙe wani ɓangaren sa cikin ingantaccen bayani mai ƙarfi. Bayan babban zafin jiki da kuma dogon lokaci homogenization magani, da Mn supersaturated a cikin matrix precipitates a cikin nau'i na Mn-dauke da mahadi, wanda aka bayyana a matsayin babban adadin tarwatsa Mn-dauke da fili bazuwar barbashi precipitated a cikin crystal (Hoto 2).

4.6 Tun da lokacin hazo ya ƙunshi nau'in Mn, yana da kwanciyar hankali mai kyau. Tare da intensification na atomic diffusion, Al (MnFe) Si lokaci barbashi sannu a hankali nuna spheroidization halaye.

Fig.3 Al (MnFe) Si lokaci a cikin 6082 alloy

5. Tasirin tsarin tsufa na bayani akan kaddarorin inji

Bayan homogenization, da cibiyar sadarwa precipitated lokaci asali a hatsi iyaka na 6082 gami da aka narkar da, wanda zai iya inganta m inji Properties na samfurin. A lokaci guda, tsayayyen lokaci mai jurewa zafi Al(MnFe)Si lokaci yana ƙara spheroidized, wanda zai iya fi dacewa da ɓarna. Wannan yana nuna cewa za a inganta ingantaccen aikin kayan aiki bayan maganin zafi na homogenization.

6. Kammalawa

6.1 6082 aluminium alloy ingot yana da haɓakar dendrites da yawa da yawa na hanyoyin hazo marasa daidaituwa na hanyar sadarwa a iyakokin hatsi.

6.2 Bayan jiyya na homogenization, duban dan tayi ya nuna cewa an rage yawan adadin matakan da aka samu sosai, kuma girman hatsi ya karu da juna. Kawarwar rabuwa da rashin daidaito lokaci ya faru a cikin ingot, kuma mahadi na cibiyar sadarwa a kan iyakokin hatsi an narkar da wani bangare.

6.3 Lokacin jefa 6082 alloy, Al(MnFe)Si lokacin hazo yana haifar da hazo. Wannan lokacin hazo ya ƙunshi nau'in Mn kuma yana da ingantaccen yanayin zafi. Kamar yadda tsarin homogenization ya ci gaba, hazo lokaci barbashi sannu a hankali nuna spheroidization halaye. Wannan ɓangarorin da ke ɗauke da Mn suna tarwatsewa iri ɗaya kuma suna haɗe cikin kristal.

6.4 Bayan maganin homogenization, rushewar hanyar sadarwar da aka haɓaka yana nuna cewa aikin gabaɗaya na duk ingot yana inganta bayan maganin zafi na homogenization.

Lokacin aikawa: Juni-08-2025