Hanyoyin sasantawa don bayanan martaba na aluminium da ake amfani da su wajen gini gabaɗaya sun haɗa da auna ma'auni da ƙa'ida. Ma'aunin aunawa ya ƙunshi auna samfuran bayanan martaba na aluminium, gami da kayan tattarawa, da ƙididdige ƙimar biyan kuɗi bisa ainihin nauyin da aka ninka ta farashin kowace ton. Ana ƙididdige ƙa'idodin ƙa'idar ta hanyar ninka nauyin ma'auni na bayanan martaba ta farashin kowace ton.

Yayin daidaita ma'auni, akwai bambanci tsakanin ainihin ma'aunin nauyi da nauyin da aka lissafta bisa ka'ida. Akwai dalilai da yawa na wannan bambancin. Wannan labarin ya fi yin nazarin bambance-bambancen nauyi da ke haifar da abubuwa uku: bambance-bambance a cikin kauri na tushe na bayanan martaba na aluminium, bambance-bambance a cikin yadudduka na jiyya, da bambancin kayan tattarawa. Wannan labarin yana tattauna yadda ake sarrafa waɗannan abubuwan don rage karkatar da su.

1.Weight bambance-bambancen lalacewa ta hanyar bambance-bambance a cikin tushe kayan kauri

Akwai bambance-bambance tsakanin ainihin kauri da kauri na ka'idar bayanan martaba, yana haifar da bambance-bambance tsakanin nauyin da aka auna da nauyin ma'auni.

1.1 Lissafin nauyi bisa ga bambancin kauri

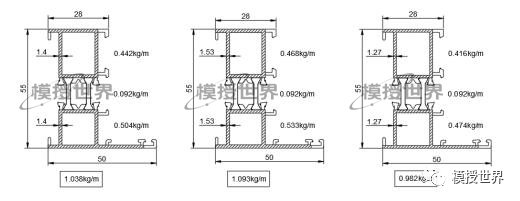

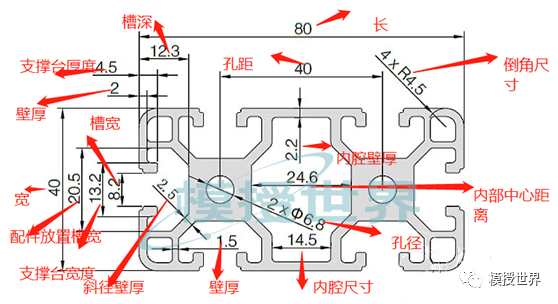

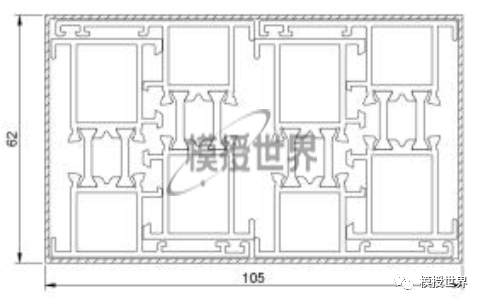

Bisa ga ma'auni na GB/T5237.1 na kasar Sin, don bayanan martaba tare da da'irar waje da ba ta wuce 100mm ba kuma kauri mai ƙima ƙasa da 3.0mm, madaidaicin madaidaicin ± 0.13mm. Ɗaukar bayanin martabar taga mai kauri 1.4mm a matsayin misali, nauyin ka'idar kowace mita shine 1.038kg/m. Tare da madaidaicin 0.13mm, nauyin kowace mita shine 1.093kg / m, bambancin 0.055kg / m. Tare da rashin daidaituwa na 0.13mm, nauyin kowace mita shine 0.982kg / m, bambancin 0.056kg / m. Kididdigar mita 963, akwai bambanci na 53kg a kowace ton, koma ga Hoto 1.

Ya kamata a lura cewa hoton yana la'akari ne kawai da bambancin kauri na sashin kauri na 1.4mm. Idan an yi la'akari da duk bambance-bambancen kauri, bambanci tsakanin nauyin nauyi da nauyin ka'idar zai zama 0.13 / 1.4 * 1000 = 93kg. Kasancewar bambance-bambance a cikin kauri na kayan tushe na bayanan martaba na aluminium yana ƙayyade bambanci tsakanin nauyin da aka auna da nauyin ma'auni. Mafi kusancin ainihin kauri shine kauri na ka'idar, mafi kusancin ma'aunin nauyi shine nauyin ka'idar. A lokacin samar da bayanan martaba na aluminum, kauri a hankali yana ƙaruwa. A takaice dai, nauyin kayan masarufi da aka samar ta irin wannan nau'in molds ya fara wuce gona da iri fiye da nauyi.

1.2 Hanyoyi don sarrafa sabawa

Ingancin gyare-gyaren bayanan martaba na aluminum shine mahimmancin mahimmanci wajen sarrafa nauyin kowane mita na bayanan martaba. Da fari dai, ya zama dole don tsananin sarrafa bel ɗin aiki da girman sarrafa kayan ƙira don tabbatar da cewa kauri na fitarwa ya cika buƙatun, tare da daidaiton sarrafawa a cikin kewayon 0.05mm. Abu na biyu, ana buƙatar sarrafa tsarin samarwa ta hanyar sarrafa saurin extrusion yadda ya kamata da kuma gudanar da gyare-gyare bayan wasu adadin ƙira, kamar yadda aka tsara. Bugu da ƙari, gyare-gyaren na iya samun maganin nitriding don ƙara ƙarfin bel ɗin aiki da rage jinkirin karuwa a cikin kauri.

2.Theoretical Weight for Daban-daban kauri Bukatun bango

Kaurin bangon bayanan martaba na aluminum yana da haƙuri, kuma abokan ciniki daban-daban suna da buƙatu daban-daban don kauri bangon samfurin. Ƙarƙashin buƙatun haƙuri na kauri na bango, nauyin ka'idar ya bambanta. Gabaɗaya, ana buƙatar samun karkatacciyar hanya ce kawai ko kuma karkatacciyar karkatacciyar hanya.

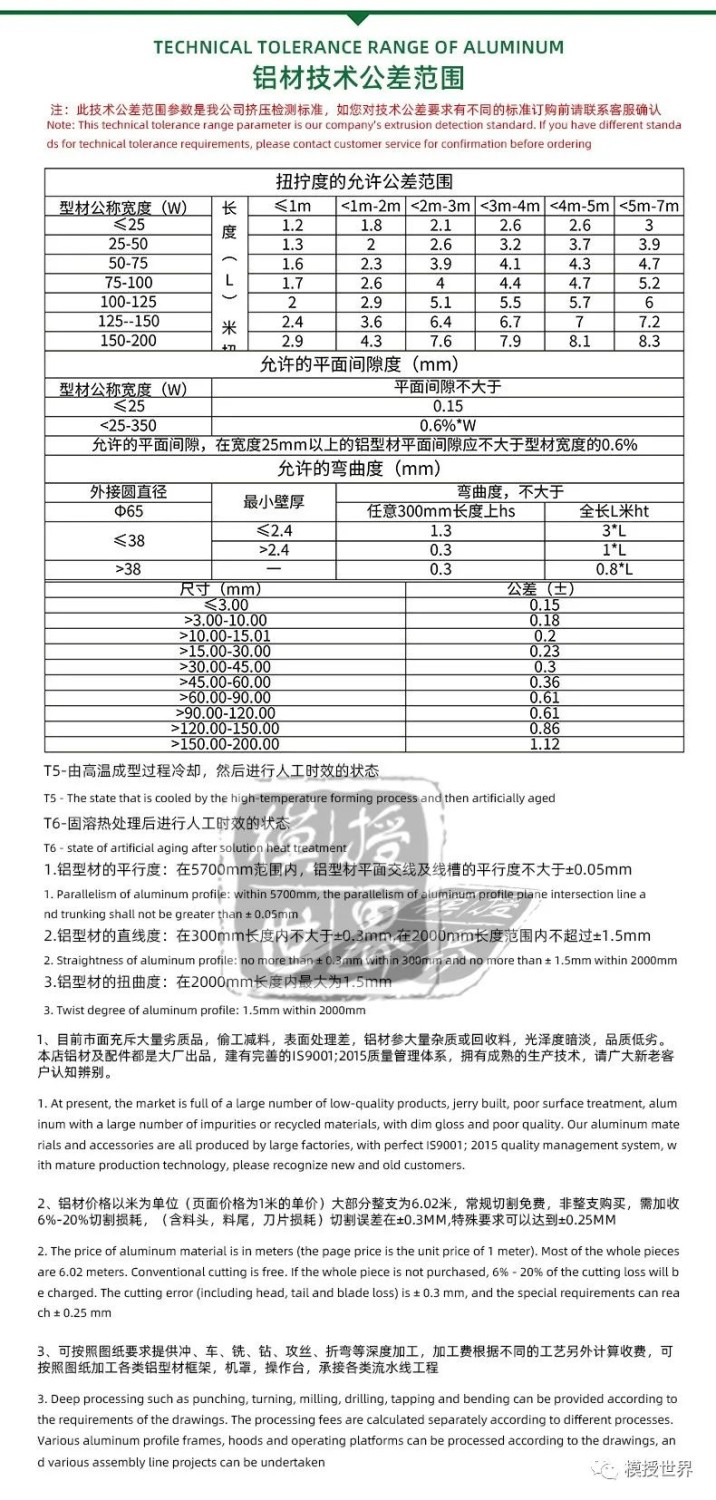

2.1 Nauyin Ka'idar don Kyawun Karɓa

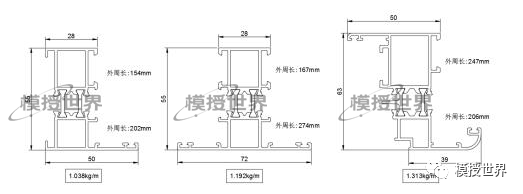

Don bayanan martaba na aluminium tare da ingantacciyar sabawa a cikin kaurin bango, yanki mai ɗaukar nauyi mai mahimmanci na kayan tushe yana buƙatar kaurin bangon da aka auna kada ya zama ƙasa da 1.4mm ko 2.0mm. Hanyar lissafi don ma'aunin ma'auni tare da tabbataccen haƙuri shine a zana zane mai banƙyama tare da kaurin bango a tsakiya kuma a lissafta nauyin kowace mita. Misali, don bayanin martaba tare da kauri na bango na 1.4mm da ingantaccen haƙuri na 0.26mm (rauni mara kyau na 0mm), kauri bango a karkacewar tsakiya shine 1.53mm. Nauyin kowace mita don wannan bayanin martaba shine 1.251kg/m. Ya kamata a lissafta ma'aunin ma'auni don dalilai na auna bisa 1.251kg/m. Lokacin da kauri na bangon bayanin martaba ya kasance a -0mm, nauyin kowace mita shine 1.192kg / m, kuma lokacin da yake a + 0.26mm, nauyin kowace mita shine 1.309kg / m, koma zuwa Hoto 2.

Dangane da kauri na bango na 1.53mm, idan kawai sashin 1.4mm ya karu zuwa matsakaicin ƙetare (Z-max deviation), bambancin nauyi tsakanin ɓacin rai na Z-max da kaurin bangon tsakiya shine (1.309 - 1.251) * 1000 = 58kg. Idan duk kauri na bango suna a karkatar Z-max (wanda ba zai yuwu ba), bambancin nauyi zai zama 0.13 / 1.53 * 1000 = 85kg.

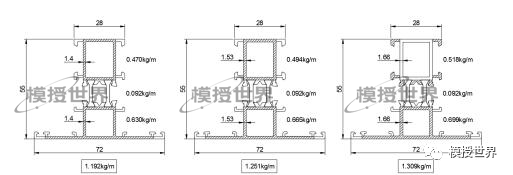

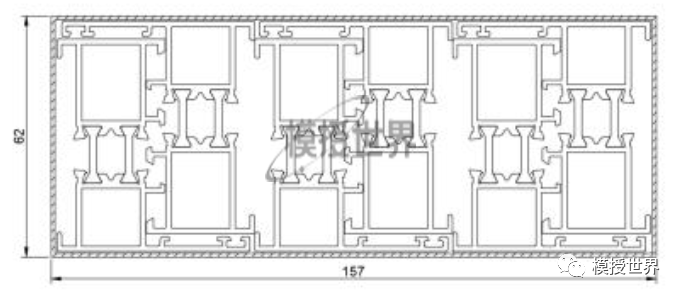

2.2 Nauyin Ka'idar don Rarraba Mara kyau

Don bayanan martaba na aluminum, kaurin bango bai kamata ya wuce ƙimar da aka ƙayyade ba, wanda ke nufin rashin haƙuri mara kyau a cikin kauri na bango. Ya kamata a lissafta nauyin ma'auni a cikin wannan yanayin a matsayin rabi na rashin kuskure. Misali, don bayanin martaba tare da kauri na bango na 1.4mm da ƙarancin haƙuri na 0.26mm (haƙuri mai kyau na 0mm), ana ƙididdige nauyin ka'idar bisa rabin haƙuri (-0.13mm), koma zuwa Hoto 3.

Tare da kauri na bango 1.4mm, nauyin kowace mita shine 1.192kg / m, yayin da kauri na bango 1.27mm, nauyin kowace mita shine 1.131kg / m. Bambanci tsakanin su biyu shine 0.061kg/m. Idan an ƙididdige tsawon samfurin a matsayin ton ɗaya (mita 838), bambancin nauyi zai zama 0.061 * 838 = 51kg.

2.3 Hanyar Lissafi don Nauyi tare da Kaurin bango Daban-daban

Daga cikin zane-zanen da ke sama, za a iya ganin cewa wannan labarin yana amfani da ƙaƙƙarfan kaurin bango na ƙididdigewa ko raguwa lokacin da ake ƙididdige kaurin bango daban-daban, maimakon yin amfani da su a kowane sashe. Wuraren da ke cike da layukan diagonal a cikin zanen suna wakiltar kaurin bango mara kyau na 1.4mm, yayin da sauran wuraren sun yi daidai da kaurin bango na ramummuka da fins, waɗanda suka bambanta da kauri na bangon ƙima bisa ga ka'idodin GB/T8478. Don haka, lokacin daidaita kaurin bangon, an fi mai da hankali kan kaurin bangon da ba a sani ba.

Dangane da bambancin kauri na bangon ƙirƙira yayin cire kayan, ana lura cewa duk kaurin bangon sabbin gyare-gyaren da aka ƙera suna da karkatacciyar karkata. Sabili da haka, la'akari kawai canje-canje a cikin kauri na bango na ƙididdigewa yana ba da ƙarin kwatancen ra'ayin mazan jiya tsakanin ma'aunin nauyi da nauyin ma'auni. Kaurin bango a cikin wuraren da ba na ƙididdigewa ba yana canzawa kuma ana iya ƙididdige shi bisa madaidaicin kaurin bango a cikin kewayon keɓantawa.

Misali, don samfurin taga da kofa tare da kauri na bango na 1.4mm, nauyin kowace mita shine 1.192kg/m. Don ƙididdige ma'auni a kowace mita don kauri na bango na 1.53mm, ana amfani da hanyar lissafin daidaitattun: 1.192 / 1.4 * 1.53, wanda ya haifar da nauyi a kowace mita na 1.303kg / m. Hakazalika, don kaurin bangon 1.27mm, ana ƙididdige nauyin kowane mita a matsayin 1.192/1.4 * 1.27, wanda ke haifar da nauyin kowane mita na 1.081kg/m. Hakanan za'a iya amfani da wannan hanyar zuwa wasu kaurin bango.

Dangane da yanayin kauri na bango na 1.4mm, lokacin da aka daidaita duk kaurin bango, bambancin nauyi tsakanin nauyin auna da nauyin ka'idar shine kusan 7% zuwa 9%. Misali, kamar yadda aka nuna a cikin zane mai zuwa:

3.Bambancin Nauyi da Ke haifar da Kauri Layer Magani

Bayanan martaba na Aluminum da ake amfani da su a cikin gini ana yawan bi da su tare da iskar shaka, electrophoresis, fesa shafi, fluorocarbon, da sauran hanyoyin. Bugu da ƙari na jiyya yadudduka yana ƙara nauyin bayanan martaba.

3.1 Girman Nauyi a cikin Oxidation da Bayanan Bayanan Electrophoresis

Bayan saman jiyya na hadawan abu da iskar shaka da electrophoresis, wani Layer na oxide film da hada fim (oxide film da electrophoretic Paint film) an kafa, tare da kauri daga 10μm zuwa 25μm. Fim ɗin jiyya na saman yana ƙara nauyi, amma bayanan martaba na aluminum sun rasa wasu nauyin nauyi yayin tsarin jiyya na farko. Haɓakar nauyi ba ta da mahimmanci, don haka canjin nauyi bayan iskar shaka da jiyya na electrophoresis gabaɗaya ne. Yawancin masana'antun aluminum suna aiwatar da bayanan martaba ba tare da ƙara nauyi ba.

3.2 Haɓaka Nauyi a Bayanan Bayanan Rufe Fashe

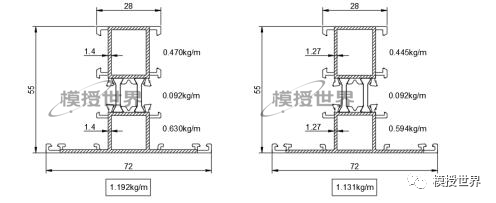

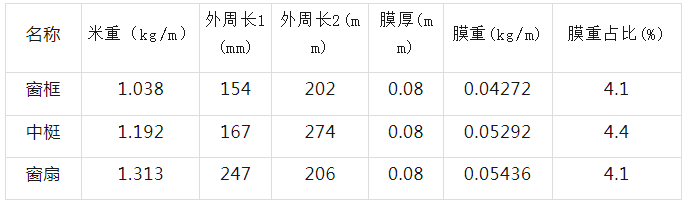

Fayilolin da aka fesa suna da murfin foda a saman, tare da kauri wanda bai gaza 40μm ba. Nauyin murfin foda ya bambanta da kauri. Ma'aunin ƙasa yana ba da shawarar kauri daga 60μm zuwa 120μm. Daban-daban nau'ikan kayan kwalliyar foda suna da ma'auni daban-daban don kaurin fim ɗaya. Don samfuran da aka samar da yawa kamar firam ɗin taga, mullions na taga, da sashes na taga, ana fesa kauri na fim ɗaya akan gefen, kuma ana iya ganin bayanan tsayin daka a cikin Hoto 4. Ana iya samun karuwar nauyi bayan fesa shafi na bayanan martaba a cikin Table 1.

Dangane da bayanan da ke cikin tebur, nauyin ya karu bayan fesa rufin ƙofofi da bayanan martaba na windows kusan 4% zuwa 5%. Don tan ɗaya na bayanan martaba, yana da kusan 40kg zuwa 50kg.

3.3 Haɓaka Nauyi a Fayil ɗin Rufe Fluorocarbon Fenti

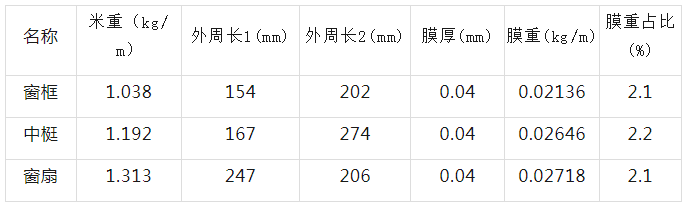

Matsakaicin kauri na rufi akan bayanan fenti mai rufin fluorocarbon bai wuce 30μm don riguna biyu ba, 40μm don riguna uku, da 65μm don riguna huɗu. Yawancin samfuran fenti masu feshin fluorocarbon suna amfani da riguna biyu ko uku. Saboda nau'in fenti na fluorocarbon daban-daban, yawan adadin bayan warkewa shima ya bambanta. Ɗaukar fenti na yau da kullun na fluorocarbon a matsayin misali, ana iya ganin karuwar nauyi a cikin Table 2 mai zuwa.

Dangane da bayanan da ke cikin tebur, nauyin ya karu bayan fesa rufin kofofin da bayanan windows tare da fenti na fluorocarbon kusan 2.0% zuwa 3.0%. Don tan ɗaya na bayanan martaba, yana da kusan 20kg zuwa 30kg.

3.4 Kula da kauri na Layer Jiyya a cikin Foda da Fluorocarbon Fenti Kayan Rufe

Kula da Layer na rufi a cikin foda da samfuran fenti mai fenti na fluorocarbon shine maɓallin sarrafa tsari a cikin samarwa, galibi yana sarrafa kwanciyar hankali da daidaiton foda ko fenti daga bindigar feshi, yana tabbatar da kauri na fim ɗin fenti. A cikin ainihin samarwa, yawan kauri na rufin rufin yana ɗaya daga cikin dalilan da ke haifar da suturar fesa ta biyu. Ko da yake saman yana goge, feshin shafi na iya zama mai kauri fiye da kima. Masu sana'a suna buƙatar ƙarfafa tsarin sarrafa suturar feshi da kuma tabbatar da kauri na suturar feshi.

4.Bambancin Nauyi da ke haifar da Hanyoyin Marufi

Bayanan martaba na aluminum yawanci ana haɗa su tare da takarda takarda ko ƙulla fim ɗin fim, kuma nauyin kayan aikin ya bambanta dangane da hanyar marufi.

4.1 Girman Nauyi a Rufe Takarda

Kwangilar yawanci tana ƙayyadad da iyakacin nauyin marufi na takarda, gabaɗaya baya wuce 6%. A wasu kalmomi, nauyin takarda a cikin tan ɗaya na bayanan martaba kada ya wuce 60kg.

4.2 Girman Nauyi a Rufe Fim

Haɓaka nauyi saboda raguwar marufi na fim gabaɗaya kusan 4%. Nauyin fim ɗin raguwa a cikin tan ɗaya na bayanan martaba bai kamata ya wuce 40kg ba.

4.3 Tasirin Salon Marufi akan Nauyi

Ka'idar fakitin bayanin martaba shine don kare bayanan martaba da sauƙaƙe kulawa. Nauyin fakiti ɗaya na bayanan martaba ya kamata ya zama kusan 15kg zuwa 25kg. Adadin bayanan martaba a kowane fakiti yana rinjayar adadin nauyin marufi. Alal misali, lokacin da aka tattara bayanan martaba na taga a cikin nau'i na 4 tare da tsawon mita 6, nauyin nauyin 25kg ne, kuma takarda marufi yana da nauyin 1.5kg, lissafin 6%, koma zuwa Hoto 5. Lokacin da aka haɗa shi a cikin sassan 6, nauyin nauyin 37kg, kuma takarda marufi yana yin la'akari da 2kg zuwa 5.

Daga alkaluman da ke sama, ana iya ganin cewa yawancin bayanan martaba a cikin kunshin, ƙananan nauyin nauyin kayan marufi. Ƙarƙashin adadin adadin bayanan martaba a kowace kunshin, mafi girman nauyin bayanan martaba, ƙananan nauyin nauyin nauyin kayan aiki. Masu sana'a za su iya sarrafa adadin bayanan martaba a kowace kunshin da adadin kayan da aka yi da kayan aiki don saduwa da buƙatun nauyi da aka ƙayyade a cikin kwangilar.

Kammalawa

Dangane da binciken da ke sama, akwai sabani tsakanin ainihin ma'aunin ma'auni na bayanan martaba da nauyin ma'auni. Rashin daidaituwa a cikin kauri na bango shine babban dalilin rashin nauyi. Ana iya sarrafa nauyin nau'in nau'in jiyya na farfajiyar sauƙi, kuma nauyin kayan marufi yana iya sarrafawa. Bambancin nauyi tsakanin kashi 7% tsakanin ma'auni da nauyin ƙididdigewa ya cika daidaitattun buƙatun, kuma bambanci tsakanin 5% shine burin masana'anta.

May Jiang ta gyara daga MAT Aluminum

Lokacin aikawa: Satumba-30-2023