6063 aluminum gami nasa ne zuwa ga low-alloyed Al-Mg-Si jerin zafi-treatable aluminum gami. Yana yana da kyau kwarai extrusion gyare-gyaren yi, mai kyau lalata juriya da kuma m inji Properties. Har ila yau, ana amfani da shi sosai a cikin masana'antar kera motoci saboda sauƙin canza launin oxidation. Tare da haɓakar yanayin motoci masu nauyi, aikace-aikacen 6063 aluminum gami da kayan extrusion a cikin masana'antar kera ya ƙara haɓaka.

Microstructure da kaddarorin kayan da aka cire suna shafar tasirin tasirin saurin extrusion, zafin jiki da haɓakar haɓaka. Daga cikin su, da extrusion rabo ne yafi ƙaddara ta extrusion matsa lamba, samar da inganci da kuma samar da kayan aiki. Lokacin da tsintsiya tsarin ƙasa ne, rashin jin damanƙara ƙarami kaɗan ne kuma gyaran microstructure ba a bayyane yake ba; ƙara extrusion rabo iya muhimmanci tace hatsi, karya sama m kashi na biyu, samun uniform microstructure, da kuma inganta inji Properties na gami.

6061 da 6063 aluminum gami suna jurewa recrystallization mai ƙarfi yayin aiwatar da extrusion. Lokacin da zafin jiki na extrusion ya kasance akai-akai, yayin da adadin extrusion ya karu, girman ƙwayar hatsi ya ragu, lokacin ƙarfafawa yana tarwatsewa sosai, kuma ƙarfin ƙarfi da haɓakar gami yana ƙaruwa daidai da haka; duk da haka, yayin da adadin extrusion ya karu, ƙarfin ƙarfin da ake buƙata don tsarin extrusion kuma yana ƙaruwa, yana haifar da sakamako mafi girma na thermal, haifar da zafin jiki na ciki na gami da haɓaka, da aikin samfurin ya ragu. Wannan gwaji yana nazarin tasirin extrusion rabo, musamman manyan extrusion rabo, a kan microstructure da inji Properties na 6063 aluminum gami.

1 Kayan gwaji da hanyoyin

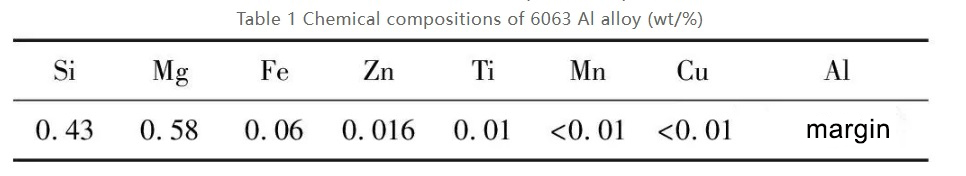

Kayan gwaji shine 6063 aluminum gami, kuma ana nuna nau'in sinadarai a cikin Table 1. Girman asali na ingot shine Φ55 mm × 165 mm, kuma an sarrafa shi a cikin billet extrusion tare da girman Φ50 mm × 150 mm bayan maganin homogenization a 560 ℃ na 6 h. Billet ɗin yana mai zafi zuwa 470 ℃ kuma yana dumi. The preheating zafin jiki na extrusion ganga ne 420 ℃, da preheating zafin jiki na mold ne 450 ℃. Lokacin da extrusion gudun (extrusion sanda motsi gudun) V = 5 mm / s zauna canzawa, 5 kungiyoyin na daban-daban extrusion rabo gwaje-gwaje da za'ayi, da extrusion rabo R ne 17 (daidai da mutu rami diamita D = 12 mm), 25 (D = 10 mm), 39 (D = 8 mm), 69 (D = 6 mm), da kuma (D = 6 mm).

Table 1 Abubuwan sinadaran 6063 Al alloy (wt/%)

Bayan niƙa takarda mai yashi da goge goge na inji, samfuran ƙarfe an haɗa su tare da reagent HF tare da ƙaramin juzu'i na 40% na kusan 25 s, kuma an lura da tsarin ƙirar samfuran akan wani microscope na gani na LEICA-5000. An yanke samfurin nazarin rubutu tare da girman 10 mm × 10 mm daga tsakiyar sashin tsayin daka na sandar da aka fitar, kuma an yi niƙa na inji da etching don cire Layer danniya. Abubuwan da ba su cika ba na jiragen kristal guda uku {111}, {200}, da {220} na samfurin an auna su ta hanyar X'Pert Pro MRD X-ray Diffraction analyzer na Kamfanin PANalytical, kuma X'Pert Data View da X'Pert Texture software ne aka sarrafa da tantance bayanan rubutu.

An ɗauko samfurin simintin simintin simintin gyare-gyaren daga tsakiyar ingot, kuma an yanke nau'in samfurin tare da hanyar extrusion bayan fitarwa. Girman yankin ma'auni shine Φ4 mm × 28 mm. An gudanar da gwajin juzu'i ta amfani da na'urar gwajin kayan duniya ta SANS CMT5105 tare da ƙimar juzu'i na 2 mm/min. An ƙididdige matsakaicin ƙimar daidaitattun samfurori guda uku azaman bayanan kayan aikin injiniya. An lura da ɓangarorin nau'ikan nau'ikan nau'ikan tensile ta amfani da ƙaramin ƙarami na sikanin lantarki (Quanta 2000, FEI, USA).

2 Sakamako da tattaunawa

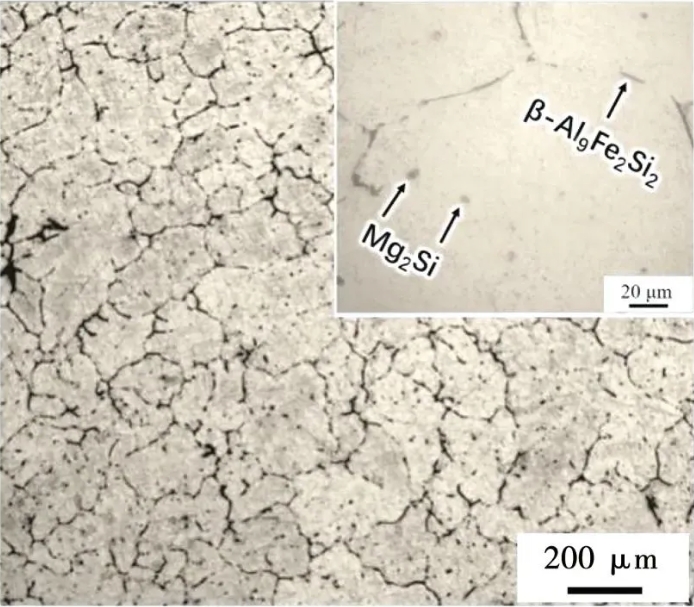

Hoto na 1 yana nuna ƙananan ƙananan ƙirar ƙarfe na simintin simintin 6063 aluminium kafin da bayan maganin homogenization. Kamar yadda aka nuna a cikin Hoto 1a, hatsin α-Al a cikin simintin simintin gyare-gyare na as-cast sun bambanta da girman, yawancin nau'ikan β-Al9Fe2Si2 na reticular sun taru a iyakokin hatsi, kuma adadi mai yawa na matakan Mg2Si na granular suna wanzu a cikin hatsi. Bayan ingot da aka homogenized a 560 ℃ na 6 h, da rashin daidaituwa eutectic lokaci tsakanin alloy dendrites sannu a hankali narkar da, da gami abubuwa narkar da a cikin matrix, da microstructure kasance uniform, da kuma talakawan hatsi size ya kusan 125 μm (Figure 1b).

Kafin homogenization

Bayan da aka yi amfani da kayan aiki a cikin 600 ° C na tsawon sa'o'i 6

Fig.1 Metallographic tsarin na 6063 aluminum gami kafin da kuma bayan homogenization magani

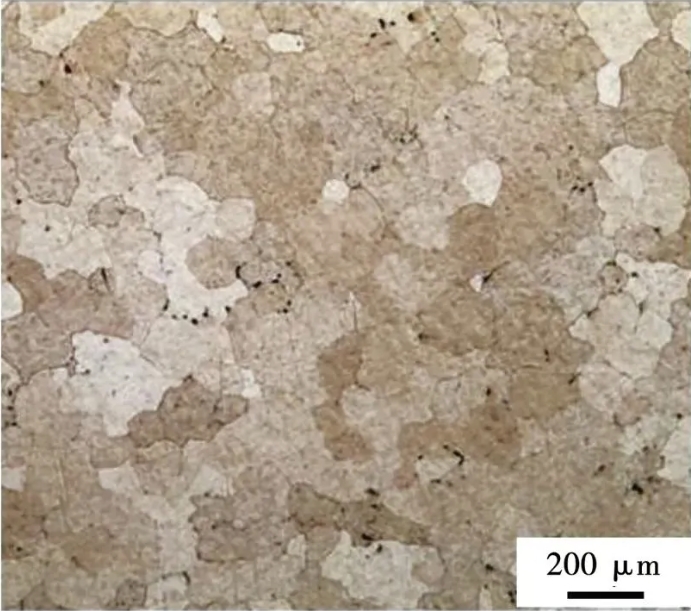

Hoto 2 yana nuna bayyanar 6063 aluminum gami sanduna tare da daban-daban extrusion rabo. Kamar yadda aka nuna a cikin Hoto 2, da surface ingancin 6063 aluminum gami sanduna extruded tare da daban-daban extrusion rabo ne mai kyau, musamman a lokacin da extrusion rabo ne ya karu zuwa 156 (daidai da mashaya extrusion kanti gudun 48 m / min), har yanzu babu extrusion lahani kamar fasa da peeling a kan surface na mashaya, kuma yana da kyau allodicating a kan surface na mashaya 60dicating. babban gudun da manyan extrusion rabo.

Fig.2 Bayyanar 6063 aluminum gami sanduna tare da daban-daban extrusion rabo

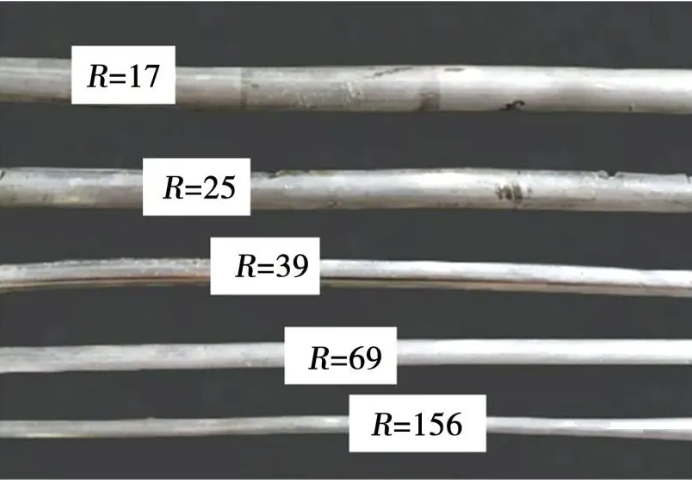

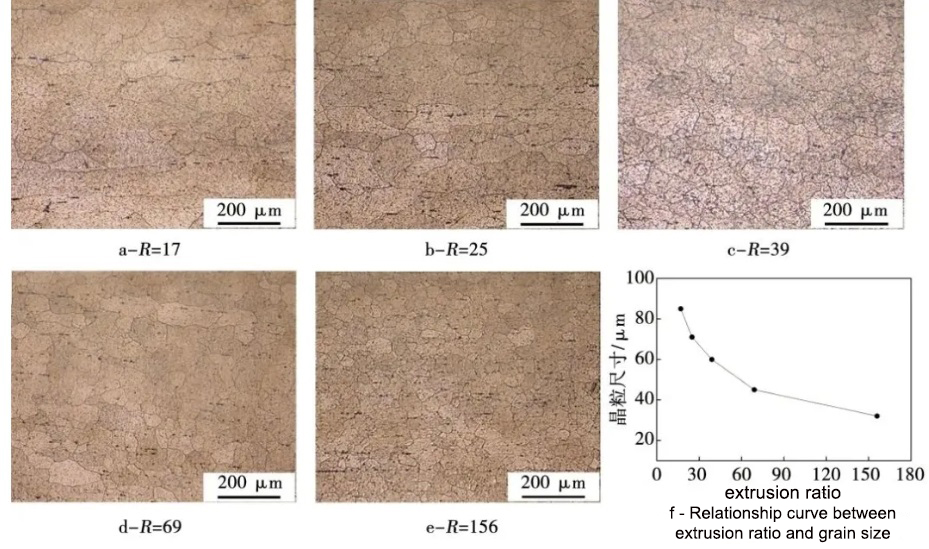

Hoto na 3 yana nuna ƙananan ƙirar ƙarfe na ɓangaren tsayi na 6063 aluminium alloy bar tare da ma'auni daban-daban na extrusion. Tsarin hatsi na mashaya tare da ma'auni daban-daban na extrusion yana nuna digiri daban-daban na elongation ko tsaftacewa. Lokacin da ma'auni na extrusion ya kasance 17, ƙananan hatsi na asali suna elongated tare da jagorancin extrusion, tare da samar da ƙananan ƙwayar recrystallized, amma hatsi har yanzu suna da ƙananan ƙananan, tare da matsakaicin ƙwayar hatsi na kimanin 85 μm (Figure 3a); lokacin da adadin extrusion ya kasance 25, an cire hatsin da yawa, yawan adadin hatsin da aka sake sakewa ya karu, kuma matsakaicin girman hatsi ya ragu zuwa kimanin 71 μm (Hoto 3b); a lokacin da extrusion rabo ne 39, sai ga wani karamin adadin maras kyau hatsi, da microstructure ne m hada da equiaxed recrystallized hatsi na m size, tare da wani talakawan hatsi size of game da 60 μm (Figure 3c); a lokacin da extrusion rabo ne 69, da tsauri recrystallization tsari ne m kammala, da m asali hatsi da aka gaba daya rikida zuwa uniformly tsara recrystallized hatsi, da talakawan hatsi size ne mai ladabi zuwa game da 41 μm (Figure 3d); a lokacin da extrusion rabo ne 156, tare da cikakken ci gaba na tsauri recrystallization tsari, da microstructure ne mafi uniform, da kuma hatsi size ne sosai mai ladabi zuwa game da 32 μm (Figure 3e). Tare da karuwa na extrusion rabo, da tsauri recrystallization tsari ci gaba da cikakken, da gami microstructure zama mafi uniform, da kuma hatsi size ne muhimmanci mai ladabi (Figure 3f).

Fig.3 Metallographic tsarin da hatsi size na a tsaye sashe na 6063 aluminum gami sanduna da daban-daban extrusion rabo.

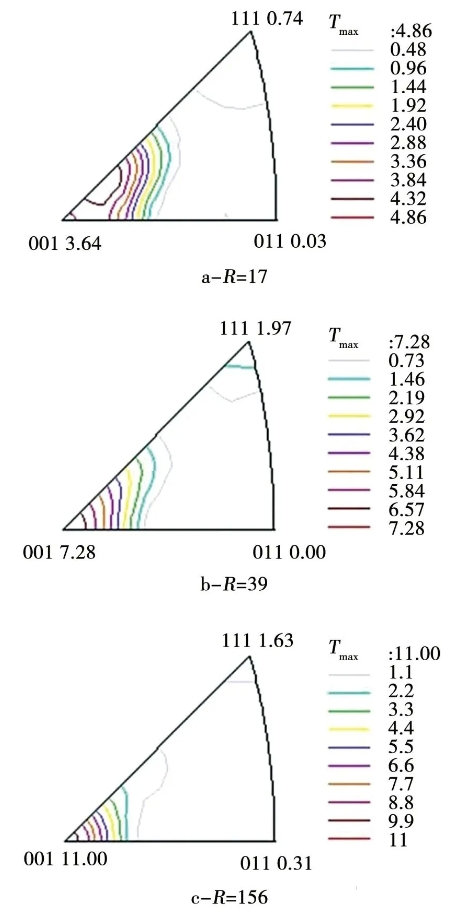

Hoto 4 yana nuna juzu'i na inverse sandal na 6063 aluminum gami sanduna tare da daban-daban extrusion rabo tare da extrusion shugabanci. Ana iya ganin ƙananan ƙananan sandunan gami tare da ma'auni daban-daban na extrusion duk suna haifar da fifikon fifiko. Lokacin da adadin extrusion ya kasance 17, an kafa mai rauni <115>+ <100> (Hoto 4a); lokacin da rabon extrusion shine 39, kayan aikin rubutun sune yafi karfi <100> rubutu da ƙaramin rauni <115> rubutu (Figure 4b); lokacin da rabon extrusion shine 156, abubuwan da aka gyara sune <100> rubutu tare da haɓakar ƙarfi sosai, yayin da <115> rubutun ya ɓace (Figure 4c). Karatun ya nuna cewa makawa na farko na farko-111> kuma <100> Rubutun Waya a cikin Fitowa da zane. Da zarar an kafa rubutun, ɗakin zafin jiki na kayan aikin gami yana nuna anisotropy bayyananne. Ƙarfin rubutu yana ƙaruwa tare da haɓakar haɓakar extrusion, yana nuna cewa adadin hatsi a cikin wani yanki na crystal daidai da jagorancin extrusion a cikin gami yana ƙaruwa a hankali, kuma ƙarfin tsayin daka na gami yana ƙaruwa. Hanyoyin ƙarfafawa na 6063 aluminum alloy hot extrusion kayan sun haɗa da ƙarfafa hatsi mai kyau, ƙarfafa ƙarfafawa, ƙarfafa rubutu, da dai sauransu A cikin kewayon sigogin tsari da aka yi amfani da su a cikin wannan gwajin gwaji, ƙara haɓakar haɓakawa yana da tasiri mai tasiri akan hanyoyin ƙarfafawa na sama.

Fig.4 Reverse sandar zane na 6063 aluminum gami sanduna tare da daban-daban extrusion rabo tare da extrusion shugabanci.

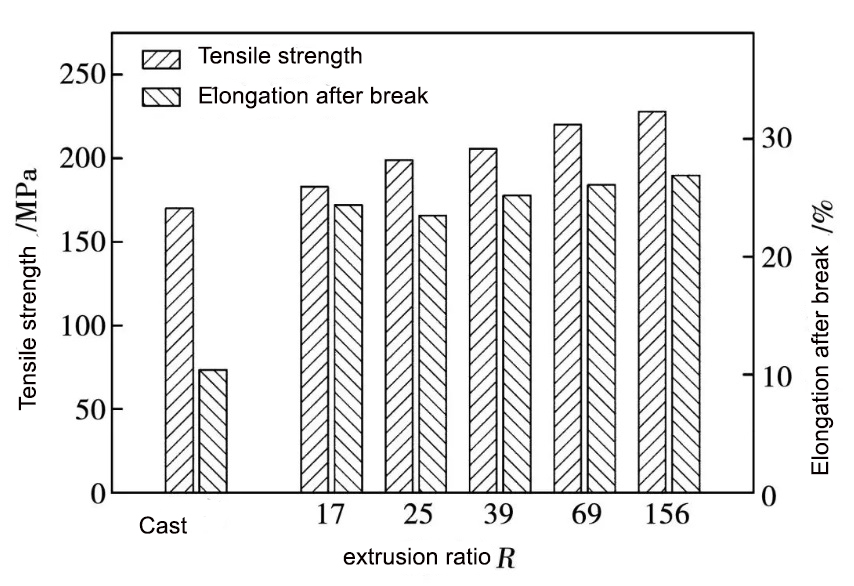

Hoto na 5 shi ne histogram na kaddarorin tensile na 6063 aluminum gami bayan nakasawa a ma'auni daban-daban na extrusion. Ƙarfin ƙarfi na simintin simintin gyare-gyare shine 170 MPa kuma haɓaka shine 10.4%. Ƙarfin ƙarfi da haɓakar haɗin gwiwa bayan extrusion an inganta su sosai, kuma ƙarfin ƙarfi da haɓakawa a hankali yana ƙaruwa tare da haɓakar haɓakar haɓakar haɓaka. Lokacin da ma'auni na extrusion shine 156, ƙarfin daɗaɗɗa da haɓakar haɗin gwiwa ya kai matsakaicin darajar, wanda shine 228 MPa da 26.9%, bi da bi, wanda shine game da 34% mafi girma fiye da ƙarfin ƙarfin simintin simintin gyare-gyare da kuma kusan 158% mafi girma fiye da elongation. Ƙarfin ƙarfi na 6063 aluminum gami da aka samu ta hanyar babban rabo na extrusion yana kusa da ƙimar ƙarfin ƙarfin ƙarfi (240 MPa) wanda aka samu ta hanyar 4-pass daidai tashar angular extrusion (ECAP), wanda ya fi girma fiye da ƙimar ƙarfin ƙarfi (171.1 MPa) wanda aka samu ta hanyar 1-wuce ECAP extrusion na 6063 aluminum gami. Ana iya ganin cewa babban rabo na extrusion zai iya inganta kayan aikin injiniya na gami zuwa wani yanki.

A haɓɓaka aikin injiniya Properties na gami da extrusion rabo yafi zo daga hatsi tace ƙarfafa. Yayin da rabon extrusion ya karu, ana tsaftace hatsi kuma yawan raguwa yana ƙaruwa. Ƙarin iyakoki na hatsi a kowace yanki na iya hana motsi na ɓarna, haɗe tare da motsi na juna da kuma haɗakar da rarrabuwa, don haka inganta ƙarfin gami. Mafi kyawun hatsi, mafi girman iyakokin hatsi, da kuma nakasar filastik za a iya tarwatsawa a cikin mafi yawan hatsi, wanda ba shi da kyau ga samuwar tsagewa, balle yaduwa. Ana iya ɗaukar ƙarin makamashi yayin aikin karaya, don haka inganta filastik na gami.

Fig.5 Tensile Properties na 6063 aluminum gami bayan simintin gyaran kafa da kuma extrusion

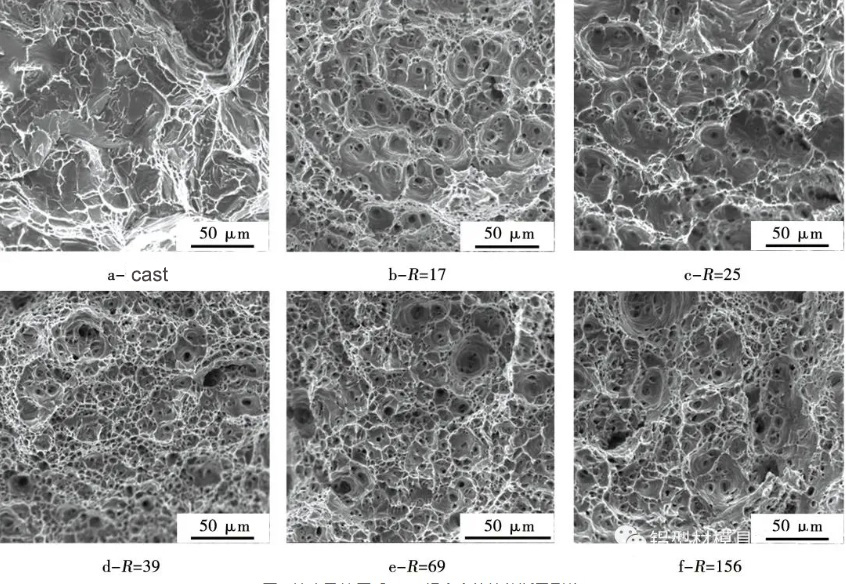

The tensile karaya ilimin halittar jiki na gami bayan nakasawa tare da daban-daban extrusion rabo aka nuna a cikin Figure 6. Babu dimples samu a cikin karaya ilimin halittar jiki na as-simintin samfurin (Hoto 6a), da kuma karaya aka yafi hada da lebur yankunan da tearing gefuna, nuna cewa tensile karaya inji na as-cast brittlecly ya main. Rashin ƙarfi na ƙwaƙwalwar ƙwaƙwalwar ƙwaƙwalwar zuciya bayan Fitowa bayan wucewa ta canza sosai, kuma karar tana da yawa na daidaitawa bayan ɓacin rai na Alloy zuwa rauni. Lokacin da adadin extrusion ya yi ƙanƙara, dimples ba su da zurfi kuma girman dimple ya yi girma, kuma rarraba ba daidai ba ne; yayin da adadin extrusion ya karu, adadin dimples yana ƙaruwa, girman dimple ya fi ƙanƙara kuma rarraba ya zama daidai (Figure 6b ~ f), wanda ke nufin cewa alloy yana da mafi kyawun filastik, wanda ya dace da sakamakon gwajin kayan aikin injiniya a sama.

3 Kammalawa

A cikin wannan gwaji, an yi nazarin tasirin ma'auni daban-daban na extrusion akan microstructure da kaddarorin 6063 aluminum gami da yanayin cewa girman billet, ingot dumama zafin jiki da extrusion gudun ya kasance ba canzawa. Ƙarshen sune kamar haka:

1) Dynamic recrystallization faruwa a 6063 aluminum gami a lokacin zafi extrusion. Tare da haɓakar haɓakar haɓakar ƙwayar cuta, ana ci gaba da tsaftace hatsi, kuma hatsin da aka haɓaka tare da jagorancin extrusion an canza su zuwa nau'in nau'in nau'in nau'i na recrystallized, kuma ƙarfin <100> rubutun waya yana ci gaba da karuwa.

2) Saboda tasirin ƙarfafawar hatsi mai kyau, ana inganta kayan aikin injiniya na gami tare da haɓakar haɓakar extrusion. A cikin kewayon gwajin sigogi, lokacin da extrusion rabo ne 156, da tensile ƙarfi da elongation na gami kai matsakaicin dabi'u na 228 MPa da 26,9%, bi da bi.

Fig.6 Tensile fracture morphologies na 6063 aluminum gami bayan simintin gyaran kafa da extrusion

3) Halittar ɓarna na simintin simintin simintin gyare-gyaren da aka yi da simintin simintin gyare-gyare ya ƙunshi wurare masu lebur da gefuna masu yage. Bayan extrusion, karaya yana kunshe da adadi mai yawa na dimples masu daidaitawa, kuma tsarin karaya yana canzawa daga raguwa zuwa karaya.

Lokacin aikawa: Nuwamba-30-2024