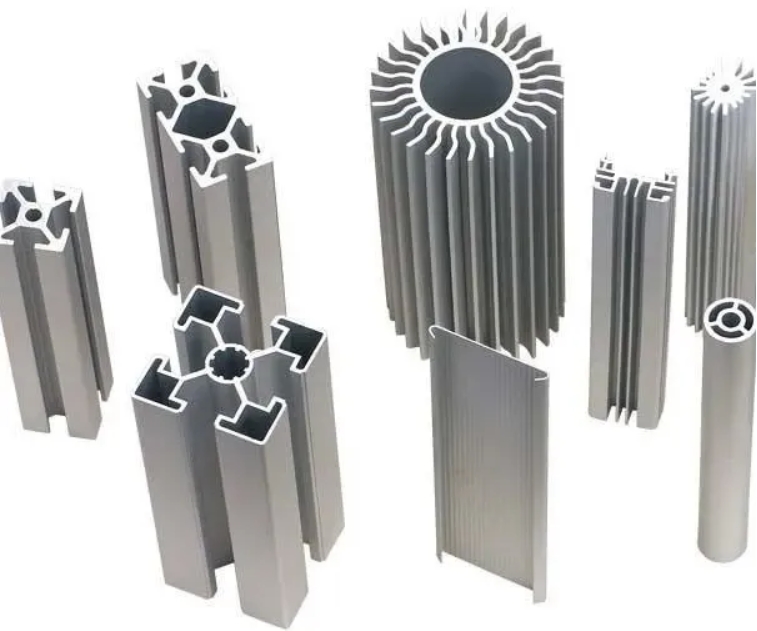

Aluminum abu ne da aka kayyade sosai don extrusion da bayanan martaba saboda yana da kaddarorin injina waɗanda suka sa ya dace don ƙirƙira da siffata ƙarfe daga sassan billet. Babban ductility na aluminium yana nufin cewa ana iya ƙirƙirar ƙarfe cikin sauƙi zuwa sassa daban-daban na giciye ba tare da kashe kuzari mai yawa a cikin injina ko ƙirƙira ba, kuma aluminum kuma yawanci yana da wurin narkewa kusan rabin na ƙarfe na yau da kullun. Duk waɗannan abubuwan biyu suna nufin cewa tsarin bayanin martabar aluminum extrusion yana da ƙarancin ƙarfi, wanda ke rage farashin kayan aiki da masana'anta. A ƙarshe, aluminum kuma yana da babban ƙarfi zuwa nauyin nauyi, yana mai da shi kyakkyawan zaɓi don aikace-aikacen masana'antu.

A matsayin samfurin tsarin extrusion, lafiya, kusan layin da ba a iya gani a wasu lokuta na iya bayyana a saman bayanin martaba. Wannan shi ne sakamakon samuwar kayan aikin taimako a lokacin extrusion, kuma ana iya ƙayyade ƙarin jiyya na saman don cire waɗannan layi. Don inganta ƙarshen sashin bayanin martaba, ana iya aiwatar da ayyukan jiyya na sama da yawa kamar niƙa fuska bayan babban tsari na ƙirƙirar extrusion. Ana iya ƙayyadaddun waɗannan ayyukan mashin ɗin don haɓaka joometry na saman don haɓaka bayanin martabar ɓangaren ta hanyar rage ƙaƙƙarfan yanayin gabaɗayan bayanin martabar da aka fitar. Ana ƙididdige waɗannan jiyya sau da yawa a aikace-aikace inda ake buƙatar madaidaicin matsayi na ɓangaren ko kuma inda dole ne a sarrafa saman abubuwan da suka dace.

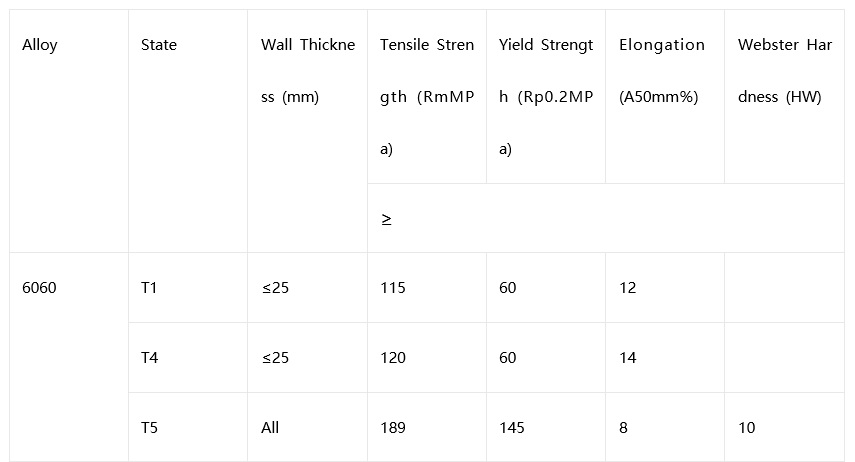

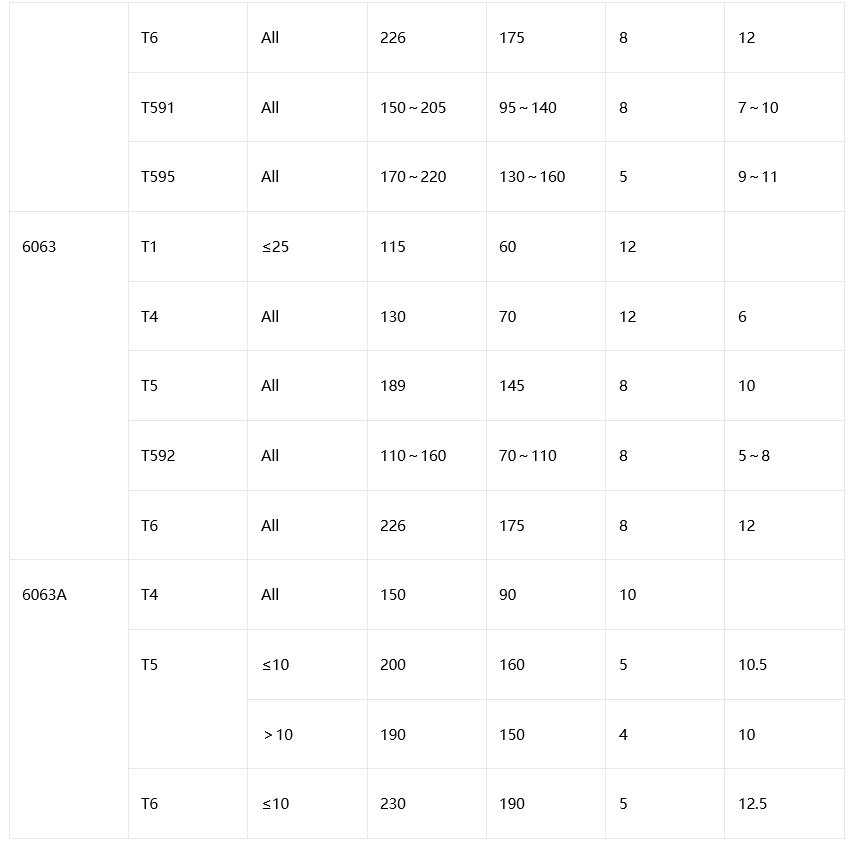

Sau da yawa muna ganin ginshiƙin kayan da aka yiwa alama da 6063-T5/T6 ko 6061-T4, da dai sauransu. 6063 ko 6061 a cikin wannan alamar alama ce ta bayanin martabar aluminum, kuma T4/T5/T6 shine yanayin bayanin martabar aluminum. To mene ne banbancin su?

Misali: A sauƙaƙe, bayanin martabar aluminum 6061 yana da mafi kyawun ƙarfi da aikin yankewa, tare da babban ƙarfi, haɓaka mai kyau da juriya na lalata; 6063 bayanin martaba na aluminum yana da mafi kyawun filastik, wanda zai iya sa kayan aiki ya sami daidaito mafi girma, kuma a lokaci guda yana da ƙarfin ƙarfi mai ƙarfi da ƙarfin yawan amfanin ƙasa, yana nuna mafi kyawun karyewa, kuma yana da ƙarfi mai ƙarfi, juriya na lalacewa, juriya na lalata da juriya mai zafi.

T4 jihar:

maganin maganin + tsufa na halitta, wato, bayanin martabar aluminum yana sanyaya bayan an fitar da shi daga extruder, amma ba tsufa a cikin tanderun tsufa ba. Bayanan martaba na aluminum wanda ba a yi shekaru ba yana da ƙananan ƙarancin ƙarfi da kuma nakasa mai kyau, wanda ya dace da lankwasawa daga baya da sauran nakasa.

T5 jihar:

maganin maganin + tsufa na wucin gadi, wato, bayan iska mai sanyaya quenching bayan extrusion, sa'an nan kuma canjawa wuri zuwa tanderun tsufa don ci gaba da dumi a kimanin digiri 200 na 2-3 hours. Aluminum a cikin wannan jihar yana da ɗan ƙaramin ƙarfi mai ƙarfi da ƙayyadaddun ƙarancin lalacewa. An fi amfani dashi a bangon labule.

T6 jihar:

bayani magani + cikakken wucin gadi tsufa, wato, bayan ruwa sanyaya quenching bayan extrusion, da wucin gadi tsufa bayan quenching ne mafi girma fiye da T5 zazzabi, da kuma rufi lokaci ne kuma ya fi tsayi, don cimma wani mafi girma taurin jihar, wanda ya dace da lokatai tare da in mun gwada da high bukatun ga kayan taurin.

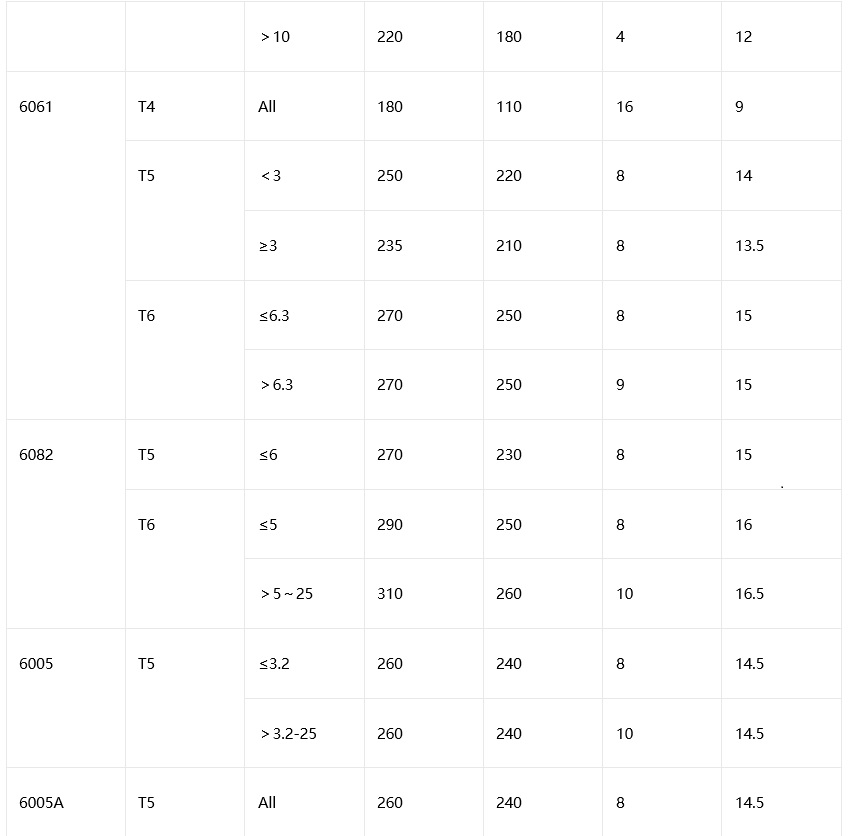

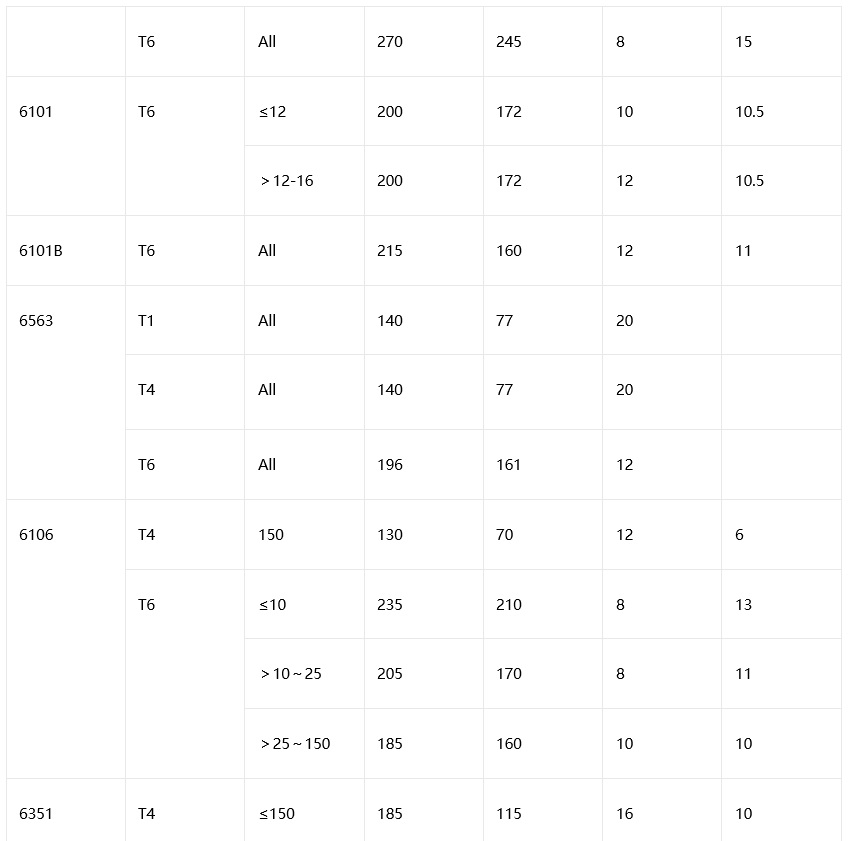

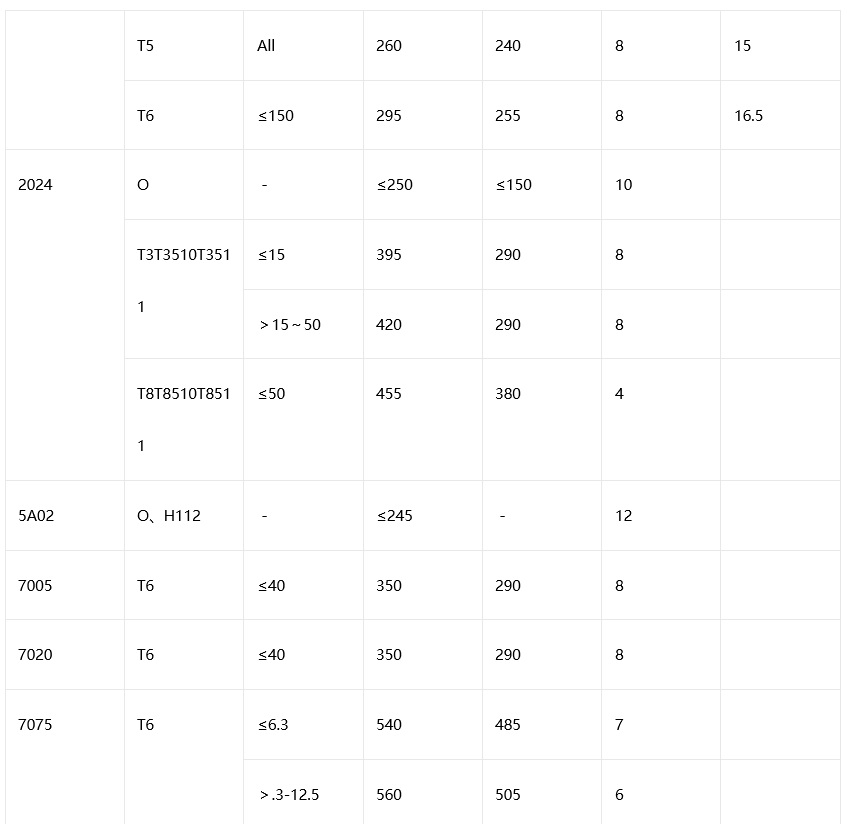

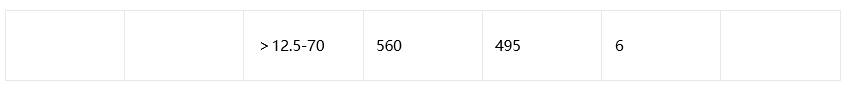

Abubuwan injiniya na bayanan martaba na aluminum na kayan daban-daban da jihohi daban-daban an yi dalla-dalla a cikin teburin da ke ƙasa:

Ƙarfin haɓakawa:

Ƙayyadaddun kayan aikin ƙarfe ne lokacin da suke samarwa, wato, damuwa da ke tsayayya da nakasar ƙananan filastik. Don kayan ƙarfe ba tare da bayyanannun yawan amfanin ƙasa ba, ƙimar damuwa da ke haifar da gurɓataccen gurɓataccen gurɓataccen abu shine 0.2% a matsayin iyakar yawan amfanin ƙasa, wanda ake kira iyakar yawan amfanin ƙasa ko ƙarfin yawan amfanin ƙasa. Sojojin waje waɗanda suka fi wannan iyaka za su sa sassan su yi kasala na dindindin kuma ba za a iya dawo dasu ba.

Ƙarfin juzu'i:

Lokacin da aluminium ya yi girma zuwa wani ɗan lokaci, ikonsa na tsayayya da nakasa yana ƙaruwa kuma saboda sake tsara hatsi na ciki. Kodayake nakasawa yana tasowa da sauri a wannan lokacin, zai iya karuwa kawai tare da karuwar damuwa har sai damuwa ya kai matsakaicin darajar. Bayan haka, ikon bayanin martaba don tsayayya da lalacewa yana raguwa sosai, kuma babban lalata filastik yana faruwa a mafi rauni. Sashin giciye na samfurin anan yana raguwa da sauri, kuma wuya yana faruwa har sai ya karye.

Taurin Webster:

Asalin ƙa'idar taurin Webster shine yin amfani da allurar da aka kashe ta wani siffa don danna cikin saman samfurin ƙarƙashin ƙarfin madaidaicin bazara, da ayyana zurfin 0.01MM azaman rukunin taurin Webster. Taurin kayan yayi daidai da zurfin shiga. Mafi qarancin shigar ciki, mafi girman taurin, kuma akasin haka.

Nakasar filastik:

Wannan nau'in nakasar ne da ba za a iya dawo da kansa ba. Lokacin da aka ɗora kayan aikin injiniya da abubuwan da suka wuce kewayon nakasawa, nakasar dindindin za ta faru, wato, bayan an cire nauyin, nakasar da ba za ta iya jurewa ba ko ragowar nakasar, wanda shine nakasar filastik.

Lokacin aikawa: Oktoba-09-2024