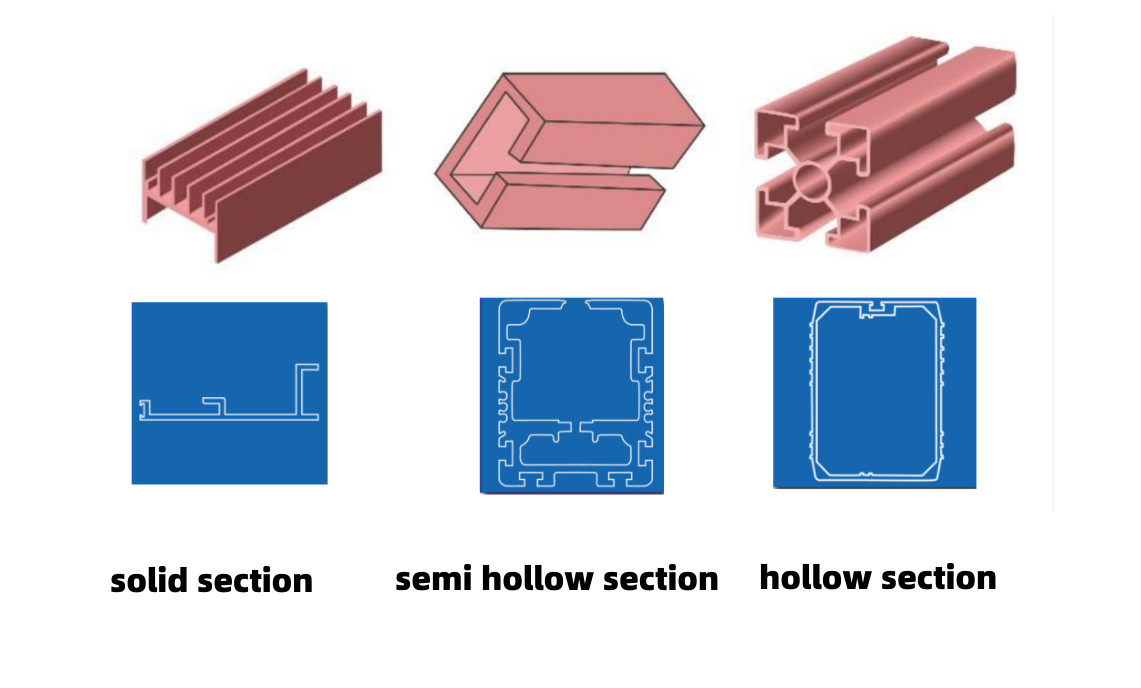

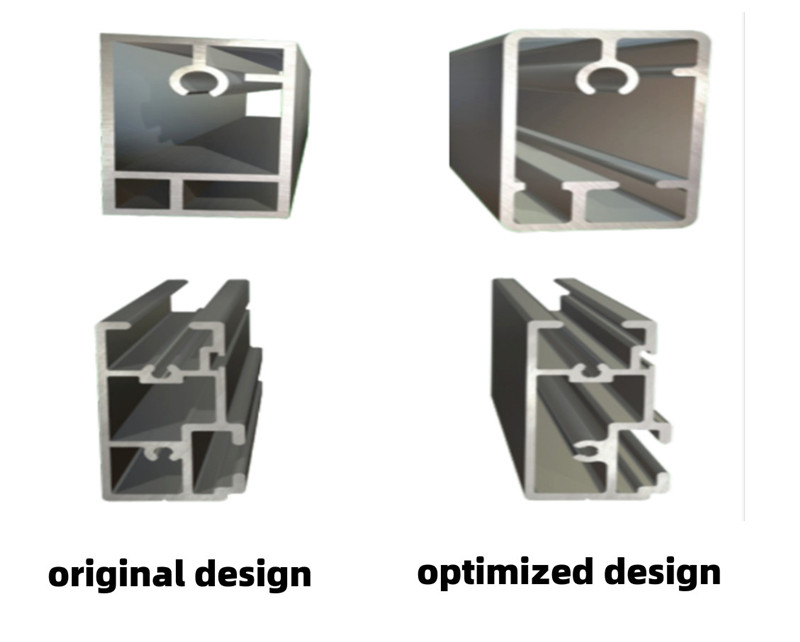

Sashin extrusion aluminum ya kasu kashi uku:

Sashe mai ƙarfi: ƙananan farashin samfur, ƙarancin ƙira

Sashin rami mai zurfi: ƙirar yana da sauƙin sawa da tsagewa da karya, tare da tsadar samfur da tsadar ƙira

Sashe mai fa'ida: babban farashin samfur da farashi mai ƙima, mafi girman farashin ƙirar ƙira don samfuran porous

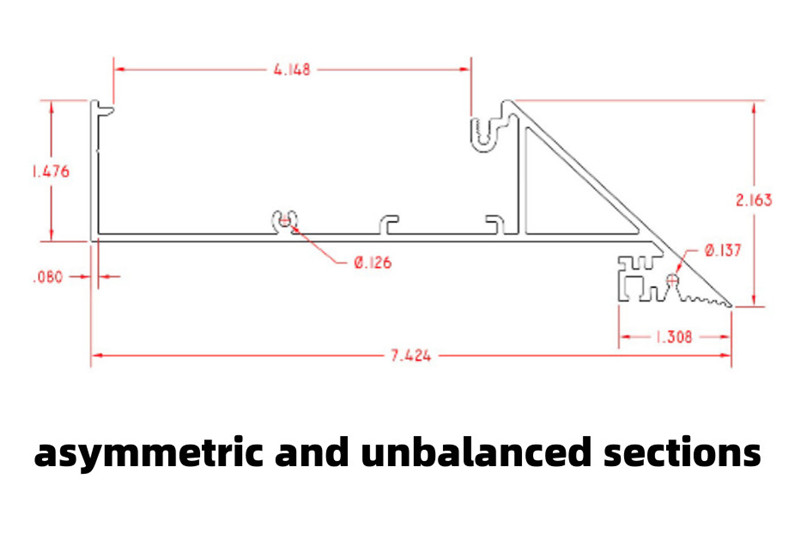

1.A guji asymmetrical da un balanced sections

Sassan asymmetric da rashin daidaituwa suna ƙara haɓakar haɓakar haɓakar haɓaka, kuma a lokaci guda, matsalolin inganci suna da haɗari don faruwa, kamar daidaiton girman girman da flatness suna da wuyar tabbatarwa, ruku'u da karkatar da sassa, ƙarancin samar da ingantaccen aiki, da kyawon tsayuwa suna da sauƙi. lalacewa da tsagewa yayin samar da yawa.

Ƙarin asymmetric ko rashin daidaituwa na sashin extrusion na aluminum, mafi wuya shi ne tabbatar da madaidaiciya, kusurwa da sauran daidaiton girman.

Ko da yake ana iya samar da sifofin asymmetrical da marasa daidaituwa, ƙarfe ba shi da yuwuwar ya kwarara zuwa kunkuntar wurare da ba daidai ba yayin extrusion, inda murdiya ko wasu batutuwa masu inganci na iya faruwa cikin sauƙi.

Har ila yau, ko da zai yiwu a extrude asymmetric da rashin daidaituwa siffofi, mafi girma kayan aiki halin kaka da kuma mafi girma samar farashin saboda a hankali extrusion gudun, ƙarshe kai ga mafi girma mold sarrafa halin kaka da kuma samar da farashin.

Mafi girman adadin bangarorin da tashoshi a cikin bayanan extrusion, ƙarancin daidaito da tsada zai kasance.

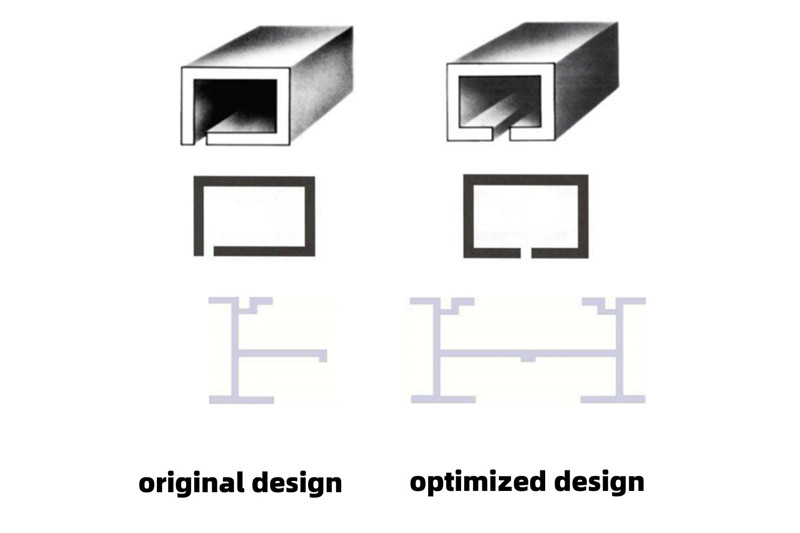

2.Mafi sauƙin siffar sashi, mafi kyau

Wasu injiniyoyin ƙirar samfura suna tsara fasali da yawa a cikin extrusion na aluminum.Ko da yake na musamman amfani da aluminum extrusions ne don ƙara ramukan, ramummuka ko dunƙule shugabannin a cikin sashe, shi zai kai ga mai matukar rikitarwa mold zane, ko ba extrudable kwata-kwata tare da tsada sosai samar farashin.

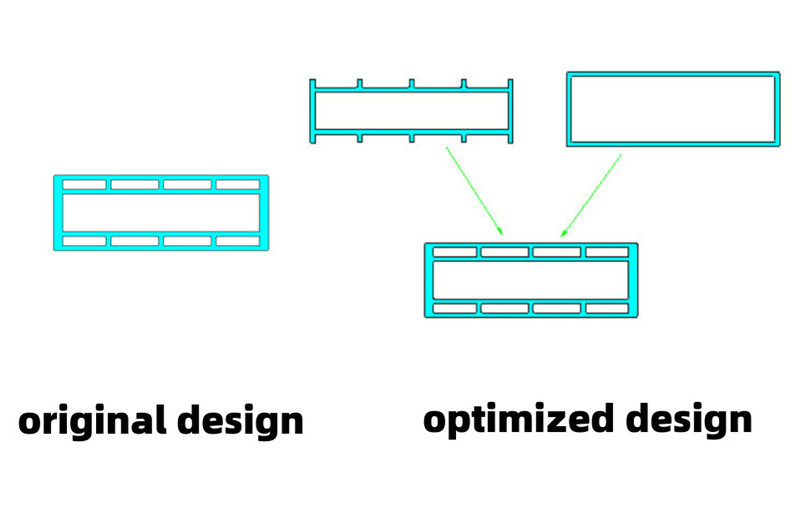

Lokacin da sashin extrusion ya yi yawa, ana iya la'akari da yin amfani da sassa biyu ko fiye don extrusion.

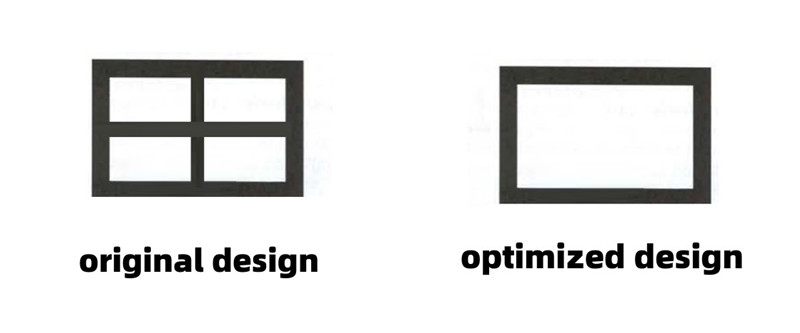

3.Porous m sashe inganta zuwa guda-rami m sashe

Ta hanyar inganta sashin ramukan ramuka zuwa cikin rami mai rami guda, ana iya sauƙaƙa tsarin ƙirar kuma ana iya adana farashi.

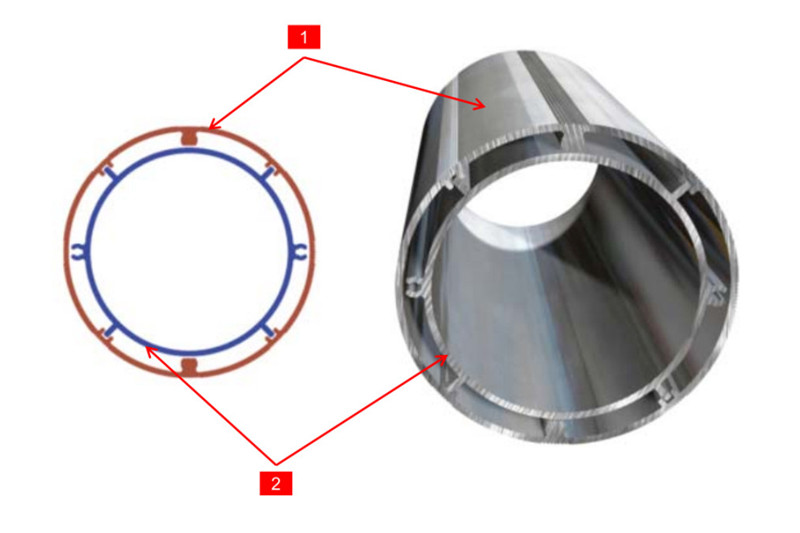

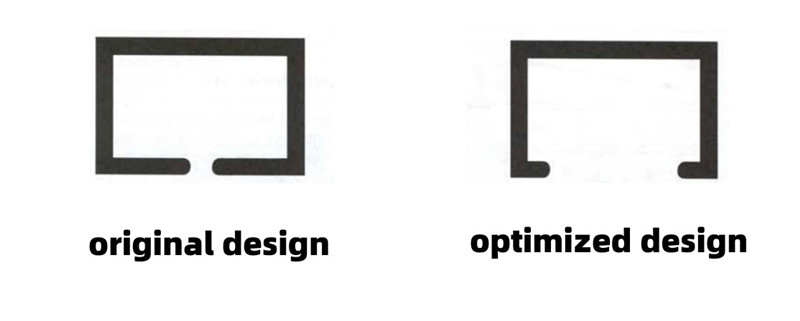

4.Hollow sashe gyara zuwa Semi-rami sashe

Ta hanyar inganta sashin rataye zuwa yanki mai raɗaɗi, ana iya sauƙaƙa tsarin ƙirar kuma ana iya adana farashi.

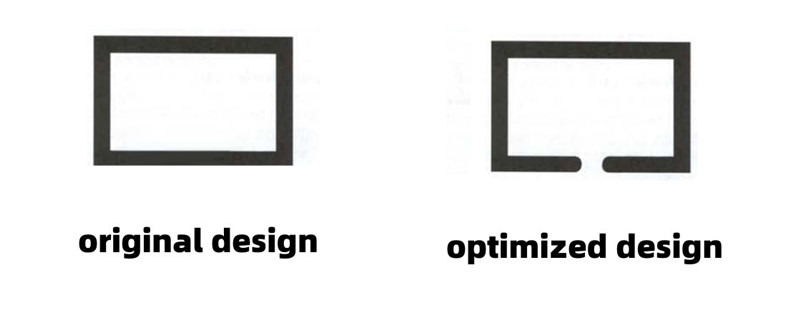

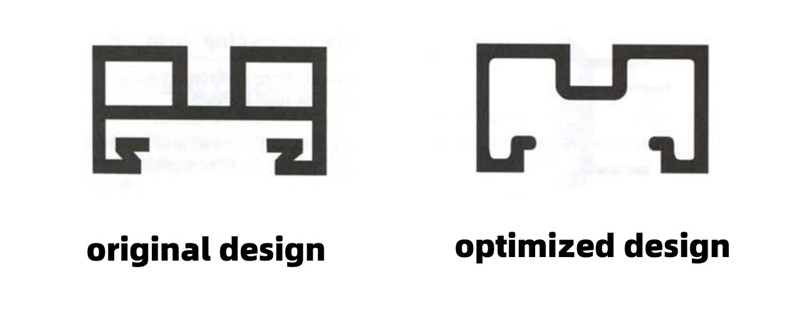

5.Semi-rami sashi gyara zuwa m sashe

Ta hanyar inganta sashin rabin-rami zuwa wani yanki mai ƙarfi, ana iya sauƙaƙe tsarin ƙirar kuma ana iya adana farashi.

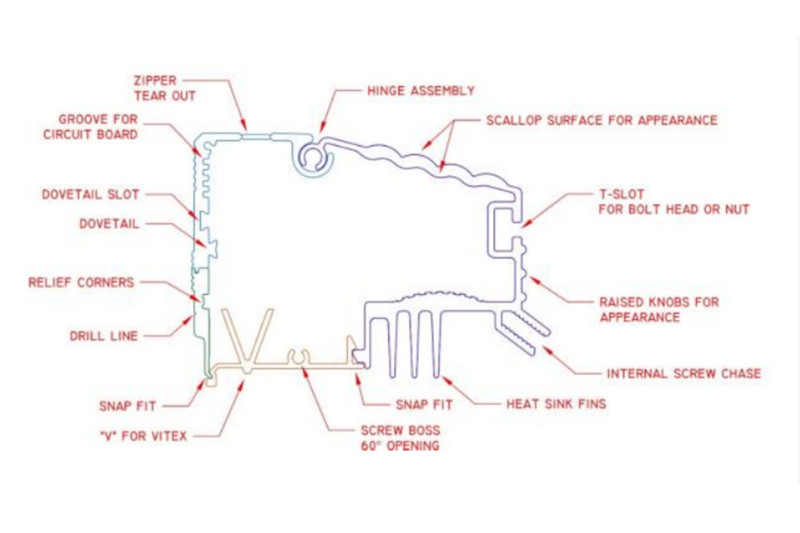

6.Kauce wa sashe mai sheki

Za a iya inganta sassan ɓoyayyen ɓoyayyen ta hanyar ƙira don rage farashin ƙira da wahalar sarrafawa da samarwa.

May Jiang ta gyara daga MAT Aluminum

Janairu 16, 2023

Lokacin aikawa: Fabrairu-18-2023